We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Noise is an occupational hazard in any shop where power tools are used. Strategies must be employed to minimize the discomforts and risks it poses to you and to the peace of your household. The problem is twofold: You need to control both the noise within the shop and the din that escapes to pollute nearby rooms and spaces.

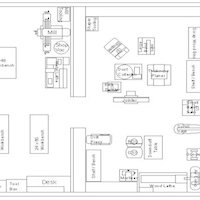

Noise Without… Two modes of sound transmission require your attention: one, through the air and, two, as transmitted through walls, ceilings, or floors.

The first is relatively easy to address. A good, tight door with weather-stripping added can lessen the volume traveling from one room to the next. But limiting the conduction of sound through walls usually requires more complicated renovations.

Applying acoustic tile to a ceiling can limit the sound traveling from a cellar workshop to the rooms above. When the problem is sound traveling through the floor to living spaces below, the floor of the workshop can be modified. A layer of sound-absorbing fiberboard can be laid on the floor; attach furring strips and plywood and vinyl flooring atop that.

New walls can be double-studded, using two-by-three studs between two-by-four plates and sills (or two-by-fours between two-by-sixes). Stagger the studs on opposite sides of the wall so that the wallboard and supporting framework on each side of the wall is independent from its mate on the other. This way, the sound is not conducted straight through the wall.

…And Noise Within. Sound inside the shop is an important issue, too. Sound can be literally deafening, short and long term. Over time, loud tools will produce actual hearing loss; in addition, too much noise also causes fatigue. In short, sound can be dangerous both to your hearing and to your safety.

Wearing protective hearing devices is the first and most obvious strategy. There are other options, too. To muffle vibrations, use rubber pads as mounts for benchtop machines. Rubber or cork feet on stationary tools can also help.

Some flooring is quieter than others. Vinyl sheet flooring is relatively inexpensive, easy to clean, and absorbs some sound. A thin underlayment (building or rosin paper or a purpose-made product from the floor store) will also help.

When purchasing machines, ask friends, local contractors, or even the salespeople about the loudness of the models you are considering. There are table saws that hum and others that positively scream.