We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Whether shaving down a wood door that’s sticking or smoothing the surface of a wavy board, no tool works quite as well as a hand planer tool. Although these simple woodworking hand tools have been around for hundreds of years, they still have a place in today’s woodshop.

These wood smoothers that run on muscle power unlike electric hand planers, are a craftsman’s best friend. Most handheld wood planers are similar in shape, but they come in a host of sizes and types, and each type performs slightly different tasks, so the best hand plane tool will depend on the particular woodworking projects done.

To help determine the best hand planes for a variety of projects, we put several popular models through their paces, evaluating finish, performance, and who they’ll truly suit, from beginner crafter to master woodworker. Learn what factors are essential in choosing the best hand plane, and discover why one or more of the models in our lineup deserves a spot in anyone’s workshop.

- BEST OVERALL: WoodRiver #4 Bench Plane, V3

- BEST EDGE RELIEF PLANER: Yogeon 4-Inch Woodworking Hand Planer

- BEST FOR TIGHT SPOTS: Stanley 12-101 3½-Inch Small Trimming Plane

- BEST FOR ROUGH LUMBER: Stanley 12-137 No. 62 SweetHeart Low Angle Jack Plane

- BEST SMOOTHING PLANE: Veritas #4 ½ Smoothing Plane

How We Tested the Best Hand Planes

The products were each tested by a professional woodworker over the course of a month. They were tested on several different pieces of test wood in a live woodworking shop and also during the manufacture of client kitchen cabinets to judge performance under real-project conditions.

Each plane was also tested to see how it would function straight out of the box, then continually used and tested after readjusting. We looked at the following aspects of each plane:

- Weight and finish: The feel and comfort of the tool in the user’s hand, as well as the overall look of the tool’s quality.

- First cut: How well the tool functions right out of the box with no other setup.

- Difficulty: How much skill is needed to set up and adjust the tool for use.

Our Top Picks

The following hand planes are meant for different jobs, and one or more of these will be a boon in a workshop whether making furniture or cabinets.

Best Overall

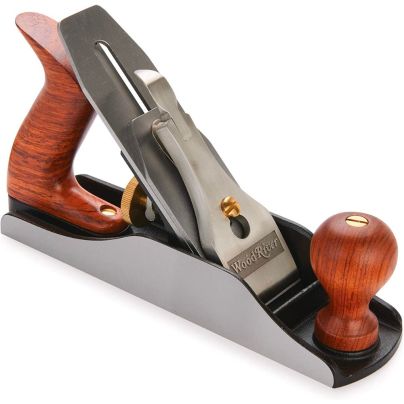

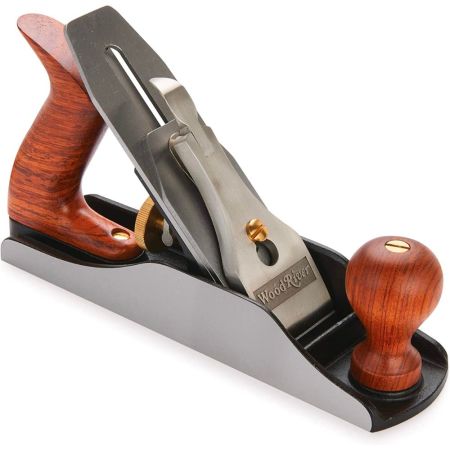

WoodRiver #4 Bench Plane, V3

See ItDesigned for the dedicated craftsman, the WoodRiver Bench Plane is a high-quality tool that can smooth both softwoods and hardwoods with ease. This full-size plane (9-7/8 inches long and 2-7/16 inches wide) has a knob in the front that can serve as a second handle, making this a two-hand plane. In testing, using the plane to flatten out an entire tabletop, it proved quick and effective.

The handle on this beautifully finished and designed plane fits comfortably in the hand for long periods of time. The plane is perfectly balanced, which makes it easy to move, while the cap iron-in blade proved particularly easy to use and adjust.

Manufactured from high-quality steel and polished wood, the WoodRiver hand plane is a good choice for shaving away high spots on large wood projects such as cedar chests or toy boxes. It’s well suited for the woodworking artisan who takes pride in creating custom projects, yet its ease of use makes it ideal for beginners as well. We consider this WoodRiver hand plane to be an heirloom-quality tool that could be passed along to future generations.

Product Specs

- Size: 9-7/8 inches long by 2-7/16 inches wide

- First cut: Very easy to use out of the box; simple setup

- Difficulty level: Beginner

Pros

- Easy-to-adjust cutting size to suit multiple projects and cutting styles

- No assembly required; ready to use right out of the box

- Excellent quality and construction for long-term use or multiple projects

- Versatile and easy to use; adjustable first handle and second handle

Cons

- Some users have reported poor quality blades; may be tricky for some users

Get the WoodRiver hand plane at Amazon or Woodcraft.

Best Edge Relief Planer

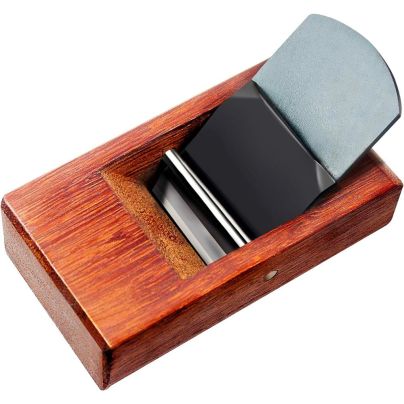

Yogeon 4-Inch Woodworking Hand Planer

See ItSmooth with or against the wood grain, or shave away the splintery ends of cut boards with the Yogeon Woodworking Hand Planer. The razor-sharp blade on this block plane is milled from ⅛-inch steel for precision and accuracy. The blade on this classic plane is fully adjustable using a mallet, and the rosewood block-style case is smooth and fits comfortably in the palm of the hand. It features a traditional wedge and iron plane and no mechanical adjustment.

Just 4-1/10 inches long and 2-2/5 inches wide, the small plane fits easily in a tool belt, so it can be kept handy at all times in the workshop or on the job site. The only wooden plane tested, it embodies the tool’s simplicity, and we found it to be a good, basic choice for putting in chamfers or doing small relief cuts and edge relief jobs. However, multiple attempts to get the wedge to hold the iron in place were required.

Product Specs

- Size: 4-1/10 inches long by 2-2/5 inches wide

- First cut: Quite tough; required significant adjusting

- Difficulty level: Intermediate

Pros

- Small size for fitting into tight spaces or for small projects; can be a portable planer for the jobsite

- Helpful instructional video included for convenience and added user-friendliness

- Affordable compared to similar options; great quality for the price

Cons

- Setup takes some time; may be tricky for first-time buyers

- Too small for surfaces; can chamfer corners and clean up small areas

Get the Yogeon hand planer at Amazon.

Best for Tight Spots

Stanley 12-101 3½-Inch Small Trimming Plane

See ItThose who took shop class in high school will probably recognize this tool. Measuring just 3½ inches long and 1 inch wide, the Stanley Small Trimming Plane is a basic plane that can shave away uneven wood in tight spots where a larger plane won’t fit. This block-type plane is made from steel, and its high-quality blade adjusts with a thumb knob or removes for hand-sharpening when necessary. This mini but durable hand plane delivers clean cuts for sculpting wood and modeling or for other types of light woodworking.

In testing, we found the Stanley 3½-inch plane to be a durable, solid tool that seemed built to last, although the overall finish is pretty generic. Those who do a lot of planing may appreciate having this small, lightweight model around. It fits easily in the hand to create a chamfered edge, yet it can also tackle planing a shoulder. While it won’t give a glasslike finish on a workpiece, it’s an ideal choice for finishing joinery. One caveat: We found that this plane required frequent readjusting during use to ensure that the blade could produce consistent shavings.

Product Specs

- Size: 3½ inches long by 1 inch wide

- First cut: Required frequent readjusting

- Difficulty level: Intermediate

Pros

- Convenient size; can be used for multiple planing types

- Shaped to hold in 1 hand, yet can still plane a larger surface

- Inexpensive compared to similar hand plane products

Cons

- Difficult to set up compared to similar options; may be tricky for first-time users

- Can be stubborn; may need frequent readjustment while in use

Get the Stanley 12-101 hand plane at Amazon, Ace Hardware, The Home Depot, or Grainger.

Best for Rough Lumber

Stanley 12-137 No. 62 SweetHeart Low Angle Jack Plane

See ItFor smoothing the surface of rough-sawn boards and timbers, the Stanley Sweetheart Jack Plane doesn’t disappoint. To do this job, a jack plane is typically larger than a standard bench model, and this one measures 15-4/5 inches long and 6-7/10 inches wide. It’s made from iron castings, weighs in at a beefy 6-plus pounds, and features two handles for controlled planing.

Part of Stanley’s Sweetheart plane line, it features a one-piece shoe and frog unit constructed from ductile cast iron milled to a tolerance of 0.003. The low-angle, one-piece base helps it glide over rough wood. Its thick steel blade improves edge retention and reduces chatter. It also features a 25-degree blade angle for less tear-out when working with highly figured wood—and this gives a quality finish on wood that has a lot of natural marking and patterns.

One issue we encountered in testing was that the handle was loose out of the box, so some adjusting was required. Additionally, the front handle is also the tightening mechanism of the mouth adjustment, so we had to be mindful when adjusting the front handle because it affected the mouth adjustment—a situation that happened multiple times during use.

Handle issue aside, this Stanley Sweetheart is a solid, high-quality tool that fits comfortably in the hand, and even the finish is beautiful, making the humble plane heirloom-worthy. Wood craftsmen who fashion projects from raw lumber will find this hand plane a great option.

Product Specs

- Size: 15-4/5 inches long by 6-7/10 inches wide

- First cut: Good; produced paper-thin full-width wood shavings

- Difficulty level: Beginner; it did require some time to set up, but it was a straightforward setup

Pros

- Throat adjustment makes quick work of large and small projects

- High-quality tool; made with iron castings and durable wood

- Straightforward adjustments; easy for changing cut types quickly and easily

Cons

- Front handle/mouth adjustment may be difficult for some users

Get the Stanley jack plane at Amazon, The Home Depot, or Acme Tools.

Best Smoothing Plane

Veritas #4 ½ Smoothing Plane

See ItAn all-purpose smoothing plane meant for fitting or sizing lumber and putting up a surface of wood, the versatile Veritas #4 1/2 can be used for a host of different tasks, such as edge jointing or truing up a surface.Veritas bench planes are known for incorporating a frog that reaches to the end of the sole, providing complete blade support that also reduces chatter and makes for a quick mouth adjustment. The manufacturer’s #4 1/2 model is no different, allowing the user to obtain narrow slits or wider openings simply by loosening two screws and setting the opening with a thumb wheel.

The plane’s body is made of fully stress-relieved ductile cast iron, with a flat, surface-ground 10-inch by 2⅞-inch sole, and a 2⅜-inch and ⅛-inch blade available in A2, O1 or PM-V11 tool steel (user’s choice). It’s comfortable to use, and the handle is big enough to accommodate larger hands.

This incredibly well-built, heirloom-quality tool worked extremely well in testing. Everything on it proved well casted, well machined, and well put-together. Even the packaging was superior, with the blade packaged separately from the plane—perhaps to help decrease damage or to allow for ordering different-type grinds.

Product Specs

- Size:10 inches long by 2-7/8 inches wide

- First cut: Frog and adjustments took some time to adjust

- Difficulty level: Advanced (but did include very helpful instructions, including a diagram, to get started)

Pros

- Well built for long-term use, durability, and/or multiple projects

- Quality function and ease of use compared to similar options

- Provides smooth cuts every time; built for blade support and reduced vibration while planing

Cons

- Lengthy initial setup and adjustment; may be tricky for first-time users

Get the Veritas hand plane at Lee Valley.

ALSO TESTED

We also tested the GreatNeck C4 9-Inch Bench Jack Plane and the Grizzly Industrial H7568 22-Inch Jointer Plane but found they did not meet our standards to be included in our Top Picks.

The GreatNeck C4 arrived in an open package and in a very damaged state. Both handles were broken, and the defective blade required an entire day’s worth of sharpening. While these issues might have been the result of an ultra-busy shipping season, unfortunately, the product we received was unusable.

The Grizzly Industrial Jointer Plane’s blade iron was slightly defective, and while this didn’t affect the tool’s performance, we consider it worth mentioning because a defect on the blade iron could have an impact on the blade stability. The blade was also a bit lighter and not as sharp as those in some other bench planes tested. We also found that the blade depth adjuster was installed incorrectly during manufacturing, and the frog was not set up correctly. What’s more, the tool arrived dirty, with an excessive amount of packaging grease that would have affected our testing workpiece had we not thoroughly cleaned it. The plane was sturdy but uncomfortable to use and produced a mediocre finish.

Jump to Our Top Picks

Types of Hand Planes

All hand planes remove excess wood by shaving it off with a blade, but within the hand plane classification, there are different types suited to specific woodworking goals.

Bench Plane

The bench plane—so called because it’s used most often at the workbench—is a two-handed plane that features a knob in the front and a handle at the rear for controlling with both hands. Its shaving blade sits at a 45-degree angle with the bevel pointing downward. The depth of the blade is adjustable, and most bench planes have a chip deflector above the cutting blade. More than 20 types of hand planes fall under the bench plane designation.

Block Plane

A block plane is a traditional woodworking tool that can be held in one hand and be used for such jobs as erasing mill marks, squaring up small stocks, beveling an edge, planing a line, or even sharpening a shop pencil. Block planes differ from bench planes in that they feature an angle of about 20 degrees instead of 45 degrees with a bevel pointing upward, not down. Block planes are best known for their versatility and convenience.

Joinery Plane

Joinery planes make the grooves and cuts necessary to fit joints together in fine woodworking. They are often named for the type of joint they cut, such as rabbet planes and dovetail planes. These hand planes come with different-size blades and guides, called shoulders, that help the user create uniform cuts and notches along the sides or ends of a wood board. There’s a wide variety of specialty joinery planes for cutting grooves and notches of various widths and depths, and with the wood grain and against it (cross-grain).

Note: Joinery planes are different from jointer planes that create flat edges for butting two pieces of wood together, such as for wood strips in a butcher-block cutting board.

Molding

The molding plane, also known as a moulding plane, creates the shapes and contours found in wood molding and trim. This time-honored hand tool has a rich history in the creation of the ornate moldings found in early European cathedrals and other decorative interiors. Often, more than one molding plane is necessary to create custom trim—a large curved plane may be used first to create a wide contour along the length of a trim board, followed by two or more smaller planes that cut grooves or rounded beads to give the trim a fancier look.

What to Consider When Choosing the Best Hand Plane

When shopping for a new hand plane, keep the following in mind.

Metal vs. Wooden

Hand planes are designed to be used in the workshop, largely for furniture building. While hand planes are made from wood or metal, in general, metal hand planes are preferred for their durability and the consistency of their results. However, some folks appreciate the look and feel of wooden planes and use them for specialized projects.

- Metal planes are the heavier option for planing wood, and woodworkers may use that extra weight to their advantage since it’s not necessary to push down hard to shave off wood. Adjusting blade depth is easier on a metal plane than a wooden one. These tools are often made from powder-coated cast iron for durability and have either metal or wood handles.

- Wooden planes are lighter than metal planes, so they’re handier for planing wood that’s upright where a heavier metal plane might be fatiguing to use. Woodworking traditionalists love the smooth feel of timeworn wood planes, and scoring one that’s a century old can be an accomplishment. However, adjusting the blade depth of a wooden plane often requires the use of a mallet, which takes time. For artisans who love wood planes, though, the extra time is well worth it.

Low Angle

Made from metal but lighter in weight than other metal planes, low-angle planes are shallower in depth and often come with thicker blades that are easy to adjust. If users are new to woodworking, a low-angle plane is an excellent choice to start with because it’s easy to set up and control.

Stanley-Bailey

If users can get their hands on a Stanley-Bailey plane, they’ll have a tool wood crafters hold in high regard. Stanley still sells high-quality hand planes today, but as of the late 20th century, Bailey is no longer part of the manufacturer’s name. Authentic Stanley-Bailey planes are still in demand by collectors because master wood craftsman Leonard Bailey—who designed the planes in the mid-1800s—created planes that made precise cuts and shaves. Stanley-Bailey planes came in various designs, including molding planes, joinery planes, and standard bench planes.

Comfortable Grip

A large knob and a curved back handle can make it more comfortable to use a heavy plane. Small hand planes often come with only a single knob for controlling the plane, and some all-wood hand planes feature just a block of wood the user grasps while sliding the plane along the wood. On a two-handle plane, the handle is typically gripped by the user’s dominant hand, while the knob in front serves as a second handle for guiding the plane. Round metal handles are acceptable, but polished wood handles absorb more vibration and impact, making them more comfortable to use.

FAQs

Hand planes can be used for a variety of projects, from building a jewelry box to crafting an entire kitchen. Those who want more info on these basic woodworking tools may find it below in the answers to some commonly asked questions about hand planes.

Q. What hand plane is good for beginners?

A decent all-around hand plane, either a #4 smoothing hand plane or a #5 jack plane will give you a good start. As you become more adept at using a hand plane, you may want to add specialty planes to your hand tool collection.

Q. What is the difference between a block plane and bench plane?

The bevel on the cutting blade faces up on a block plane, which is better for planing against the grain or end grain. On a bench plane, the bevel faces down; this is ideal for cutting with the grain in preparing a piece for finishing.

Q. What is a jointer plane used for?

Jointer planes are the longest planes available, ranging from 22 to 30 inches in length, and their purpose is to flatten out curves in boards.

Why Trust Bob Vila

Bob Vila has been America’s Handyman since 1979. As the host of beloved and groundbreaking TV series including “This Old House” and “Bob Vila’s Home Again,” he popularized and became synonymous with “do-it-yourself” home improvement.

Over the course of his decades-long career, Bob Vila has helped millions of people build, renovate, repair, and live better each day—a tradition that continues today with expert yet accessible home advice. The Bob Vila team distills need-to-know information into project tutorials, maintenance guides, tool 101s, and more. These home and garden experts then thoroughly research, vet, and recommend products that support homeowners, renters, DIYers, and professionals in their to-do lists.