We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Trying to make a list of the best woodworking tools is something of a challenge. Whether the tools are for general-purpose use, for experienced DIYers, for fine cabinet makers, or are woodworking tools for beginners, the types of tools chosen can make a difference. The list could also focus on the latest power tools or include traditional hand tools.

There is no simple one-size-fits-all list of best tools that suits every type of tool user in every application at every price point, but there are a number of categories that are consistently popular among many types of tool users. Starting with perennial favorites like saws, drills, planers, and sanders, we can build a selection of some of the best woodworking tools currently available that will suit most people, most of the time.

- BEST OVERALL: DEWALT Sliding Compound Miter Saw, 12-Inc

- BEST JIGSAW: SKIL 6 Amp Corded Jig Saw

- BEST TABLE SAW: SKIL 15 Amp 10 Inch Table Saw

- BEST DRILL DRIVER: DEWALT 20V Max Cordless Drill / Driver Kit

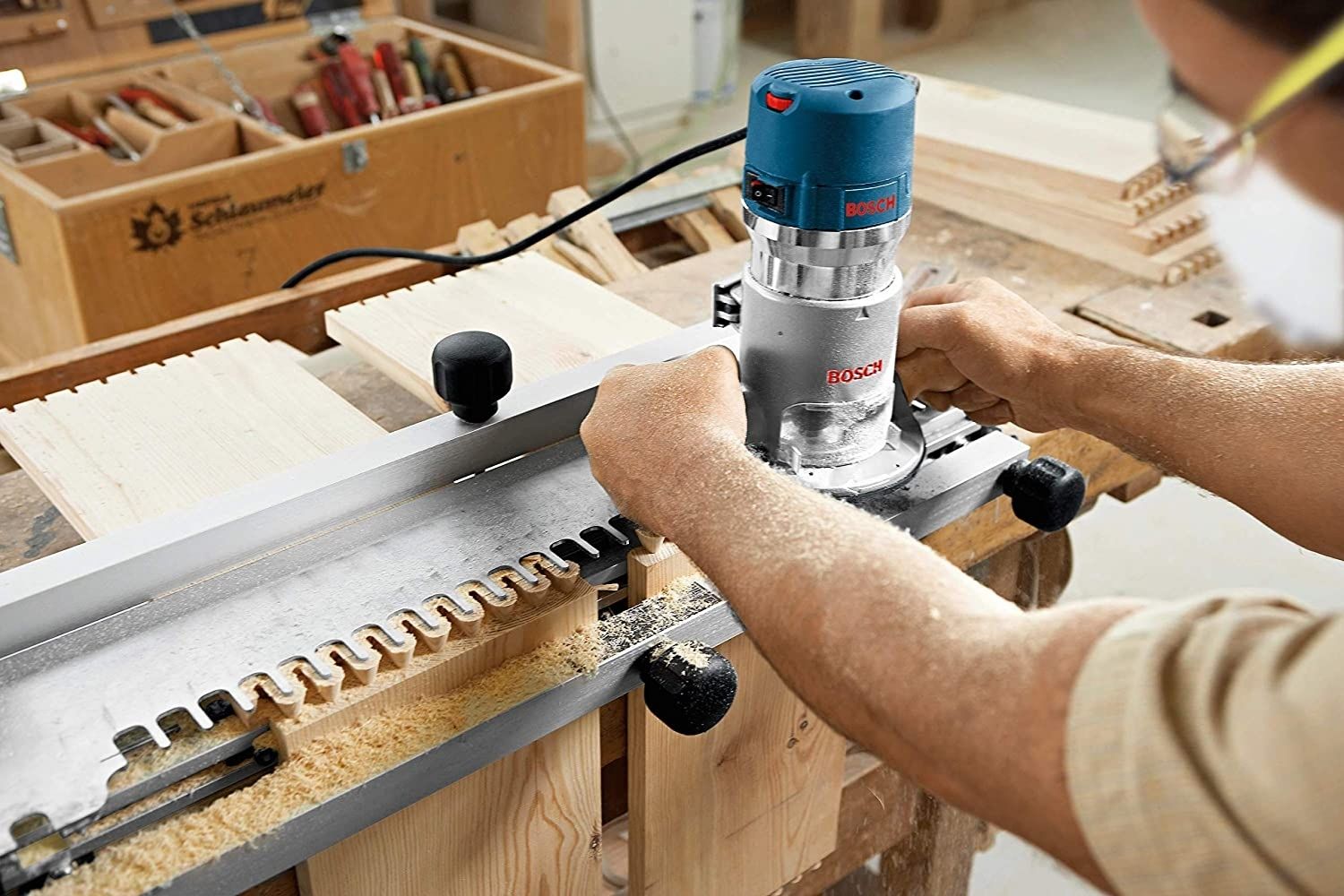

- BEST ROUTER: Bosch 1617EVSPK Wood Router Tool Combo Kit

- BEST RANDOM ORBITAL SANDER: Makita 18-Volt LXT Lithium-Ion Random Orbit Sander

- BEST WOOD CHISELS: REXBETI 10pc Premium Wood Chisel Set

- BEST BENCH GRINDER: Delta 8-in Grinder Model #23-197

- BEST DUST COLLECTOR: SHOP FOX W1727 1 HP Dust Collector

What to Consider When Choosing the Best Woodworking Tools

There are many factors to consider when shopping for woodworking tools, including budget, workshop space, compatibility with other tools, and safety features, but quality and durability are typically two of the most important key features to look for when it comes to tools. Understanding the typical uses for different types of woodworking tools can also help make it easier when deciding on which tool will add the most value to a tool user’s shop.

Types of Woodworking Tools

The variety of tools is vast, from traditional hand joinery tools to the latest woodworking power tools. Below is an overview of each type of tool, the tool category’s functionality, and the important features to look for. While some basic woodworking tools didn’t make our list of top picks, it’s not because they aren’t of value. Many tool users typically already own the very basics as part of a general DIY tool set, and the basics are not specifically intended for woodworking.

Saws

Saws are perhaps the most essential of woodshop tools. Nothing can be made until the wood is cut. Their importance is underlined by the enormous choice, from a small gent’s saw for cutting decorative joints to huge table saws that can rip through large sheet material and boards in moments.

For a beginner woodworking tool setup, this means a choice of miter saws, table saws, bandsaws, jigsaws, and circular saws. Most woodworking enthusiasts will have at least two of these. While there are overlaps, it’s important to investigate the main differences.

With miter saws (also called chop saws), table saws, and bandsaws, the work is taken to the saw.

- Miter saws are great for cutting boards and posts, but can have limited reach.

- Table saws are for sheet material and boards, cutting straight lines (ripping) quickly and accurately. They have limited depth.

- Bandsaws offer good versatility and are the only large saw that can cut curves, but material width is limited.

With jigsaws and circular saws, the saw is taken to the work.

- Jigsaws can be seen as the portable version of the bandsaw. They are great for cutting curves. While they can cut straight lines, more concentration is required.

- Circular saws are a little like a portable table saw. While they are a good choice for sheet material, they cannot cut curves.

Planing and Sanding

Once the wood has been sawn, it often needs to be planed to the required size, and then sanded to a smooth finish.

Planing by hand has long been considered a test of a craftperson’s skill, and it can be very rewarding. However, doing it well takes time. Power planers and thickness planers do the job much more quickly. Powered hand planers are a motorized version taken to the workpiece. Thickness planers, as the name suggests, quickly reduce the thickness of a board. Power planers are used to true up the side (face) of a board and the edge. Combined planers are available, but they tend to be large tools for professional workshops.

Powered sanders vary considerably from detail sanders designed to get into small spaces, through light and highly maneuverable palm sanders, to general-purpose random orbital sanders. The latter is probably the best choice for beginners because of its versatility with both large and relatively small workpieces. Drum and belt sanders are also options, but these are more often found in professional shops or used by trade carpenters.

Assembly Tools

Assembly tools for woodworking are quite basic, but nevertheless important. Below are some of the most common types of assembly tools found in a woodworking shop.

Hammers. Pretty much every home tool set includes a hammer, but the hammer used for putting panel pins into plywood needs to be a lighter tool with a smaller head than the one used for knocking in 6-inch nails.

Nailers. Power nailers are another consideration. While finish nailers can have applications for woodworking, they are more often used as remodeling or trade carpentry tools.

Drills. Drill drivers are part of many DIY tool kits and are another woodworking essential. Screws have more holding power than nails and generally provide a neater and more precise fixing. Pillar drills—freestanding drills—are a valuable addition to higher productivity shops, both amateur and professional.

Clamps. Most keen woodworkers can never have too many clamps. They are vital when gluing up material. Their modest cost means a variety of sizes can be purchased.

Jointers. Those putting together workbenches, tabletops, or similar projects may want to look at biscuit jointers, which offer a fast and accurate way to join multiple boards.

Measurement Tools

Measuring tools for woodworkers range from a basic steel tape to high-precision vernier calipers, though the latter is a somewhat specialist tool.

- Tape or ruler: Tape measures are fine for general carpentry but over time, the end tends to come loose and some of the accuracy is lost. A steel rule is a durable alternative favored by many.

- Try square: A try square is absolutely essential for marking out 90-degree angles, and these also incorporate a graduated scale.

- Combination square: A combination square combines a steel rule and a sliding block with surfaces for both 45- and 90-degree angles. A spirit level bubble is usually incorporated in a combination square for checking level.

- Sliding bevel: A sliding bevel may not have markings for measurement, but it is a useful tool that can be set at any angle, then laid against the workpiece to transfer cut lines or markings for drilling.

Other Tools

Keeping the woodshop clean is few people’s favorite task but can impact working in it on several levels. A clean workshop is safer, tools work better, and equipment lasts longer. Plus, sawdust can ruin the finish of a job.

Shop vacs are often a tough and economical solution. Some can clean up not just sawdust but nails, screws, and other debris. Many can also deal with water.

A more focused option for keen woodworkers is a dedicated dust extractor. These can be attached to individual woodworking machines, or a system of ducting and “blast gates” can be created that provides extraction for the whole workshop. Dust extractors also often have a higher level of filtration, so fewer small particles are left in the air.

Safety Equipment

Most woodworking tools incorporate valuable safety features. If a tool is capable of cutting, sanding, or drilling wood, then it has the potential to cause serious harm to hands and fingers. Sawdust can get into eyes, nose, and mouth. Some exotic hardwoods produce toxic dust when worked and can severely irritate the respiratory system.

Eye protection, either safety glasses or goggles, should always be worn. At minimum, a lightweight dust mask should be used. Some machinery is loud, and the OHSA (Occupational Health and Safety Administration) recommends ear protection for noise levels above 85 decibels. While not a legal requirement in home woodshops, in addition to protecting hearing, ear protection also helps reduce fatigue.

As far as woodworking machinery is concerned, always read manufacturer guidelines, and never remove any guards or shields.

Our Top Picks

In selecting our top picks, we have gone beyond the most basic essentials, which often form part of DIY tool kits. While there may be cheaper woodworking tools available, and we often include budget picks in other top picks lists, we are focusing on the higher quality tools that are expected to provide many years of service. Initial cost might be higher, but the fact that they frequently outperform and outlast their competitors means they also represent excellent value. The following tools are specifically for woodworkers, from those just starting out to full-time professionals.

Best Overall

DEWALT Sliding Compound Miter Saw, 12-Inch

See ItCompound miter saws can cut vertical angles, horizontal bevels, or combinations. The DeWalt sliding compound miter saw can also slide forward, giving 6¾-inch depth of cut at the fence, or up to 2-inch by 14-inch width. The sliding action can be locked out when not required. The saw bevels to 48 degrees both left and right.

A combination fence provides good support for tall items, and extending arms fitted on both sides support longer workpieces. A workpiece clamp can be used on either side of the blade. There are clear scales throughout and 10 positive stops (detents) for rapid setting of common angles via a quick-lock handle.

At 56 pounds the DeWalt isn’t light, but it remains reasonably portable. The supplied general-purpose blade is adequate but produces a fairly coarse cut. The dust collecting bag would benefit if it was larger. Fitting a shop vac or extractor would be a better idea where practical.

Product Specs

- Power: Corded, 15 amps

- Maximum width of cut: 14 inches

- Weight: 56 pounds

Pros

- High build quality and durability

- Excellent performance and capacities

- Very user-friendly

Cons

- Supplied blade could be better

- Dust bag has a limited capacity

Best Jigsaw

SKIL 6 Amp Corded Jig Saw

See ItThe SKIL 6-amp jigsaw offers tremendous versatility with the ability to crosscut boards or cut complex shapes in plywood or MDF. By changing the blade it can handle wood, plastic, aluminum, and even steel sheet. Blades use a U-shape fitting rather than the more common T-shape, though both are widely available.

A four-position orbital cutting action can be adjusted to suit different materials. The foot (base plate) can be angled to cut bevels. Often jigsaws need an Allen wrench to do this, but the Skil has a simple, fast-acting lever.

There are four speed ranges, again adjusted to suit the material being cut. This makes it easier to maintain constant speed, although inexperienced users might prefer a variable trigger for a slow speed at the start of the cut.

Product Specs

- Power: Corded, 6 amps

- Speed: Up to 3,200 strokes per minute (spm)

- Weight: 4.9 pounds

Pros

- Tool-free blade changing

- Quick-set shoe mechanism for bevels

- Work light illuminates cut line

Cons

- Uses less common U-shank blades

- Trigger is not fully variable

Best Table Saw

SKIL 15 Amp 10 Inch Table Saw

See ItThose who cut a lot of sheet material or boards might find a table saw a better choice than a miter saw. While the latter can take up a lot of space and be expensive, the compact SKIL table saw is a good compromise between size and performance and is also very affordable.

The 10-inch blade offers a 3½-inch depth of cut at 90 degrees, which is enough for 4×4 dimensional lumber. Depth is 2½ inches when beveling at 45 degrees. Maximum ripping width is 25½ inches to the right side of the blade and 14 inches to the left. The fence has a smooth accurate rack-and-pinion adjustment. A miter gauge is included for angled cuts.

The SKIL table saw also benefits from integral folding legs, allowing it to be used on a benchtop if workshop space is limited. It is also relatively portable.

Product Specs

- Power: Corded, 15 amps

- Cutting capacity: Up to 4×4 dimensional lumber

- Weight: 51.2 pounds

Pros

- 25½-inch ripping capacity

- Accurate and stable fence

- Folds for storage and portability

Cons

- Modest table size

- Legs are a little finicky

Best Drill Driver

DEWALT 20V Max Cordless Drill / Driver Kit

See ItThere are lots of very good drill drivers around, but as a complete package the DeWalt 20V Max cordless is hard to beat. The ½-inch keyless chuck reflects its heavy-duty nature. There are two speed ranges giving greater control over drilling or driving tasks. There is also a 16-position clutch allowing precise adjustment of torque.

The DeWalt drill/driver weighs just 3½ pounds, and its compact size makes it useful in confined spaces. An LED work light brightens dark corners. It uses a brush motor, rather than the more efficient brushless type, but it does offer proven reliability and helps keep costs down.

The only minor negative is that the included 1.5-amp-hour (Ah) battery does restrict runtime. Many users will want to invest in a spare, and we would recommend a 3-Ah battery or higher.

Product Specs

- Power: Cordless, 20 volts

- Chuck size: ½-inch

- Weight: 3.64 pounds

Pros

- Reliable, high-performance drill driver

- Two speed ranges

- Includes drill, battery, charger, and sturdy bag

Cons

- Included battery is only 1.5 Ah

- Brush motor not as efficient as brushless

Best Router

Bosch 1617EVSPK Wood Router Tool Combo Kit

See ItOne of the big questions when choosing a router is whether to go for a fixed base or a plunge model. Bosch overcame the issue by including both in a high-quality, competitively priced kit. Versatility is increased by the inclusion of both ¼-inch and ½-inch collets, so an enormous range of router bits can be used.

As many expect from Bosch, the router employs some clever electronics. The Soft Start reduces the router’s initial tendency to twist sharply, making control easier. Its “constant response circuitry” means the motor delivers increased power if it starts to bog down. A small but nevertheless thoughtful addition is that the on-off switch can be fixed on either side for left- or right-handed users.

Product Specs

- Power: Corded, 12 amps

- Speed: 8,000 to 25,000 rpm

- Weight: 7.7 pounds (with fixed base)

Pros

- Powerful 2¼-horsepower motor

- Switch easily from fixed to plunge base

- Micro height adjustment for precision

Cons

- Height adjustment is a little finicky

- An edge guide is extra

Best Random Orbital Sander

Makita 18-Volt LXT Lithium-Ion Random Orbit Sander

See ItThe freedom of movement offered by the Makita cordless random orbital sander can be a major benefit, particularly when working over large areas. A one-touch speed control switches easily among 7,000, 9,500, and 11,000 oscillations per minute, so the Makita sander can change quickly from rapid material removal to fine finishing.

The Makita has a class-leading 5-Ah battery unit that will run the tool for up to an hour on low speed, and a half hour on the fastest setting. Recharging is rapid, taking just 45 minutes. The ergonomic hand grip provides good control over horizontal surfaces, though a second hand may be needed to maximize control if sanding vertically.

If the Makita cordless orbital sander is beyond the budget, the company also produces an excellent corded version that costs considerably less money.

Product Specs

- Power: Cordless, 18 volts

- Speeds: 7,000 / 9,500 / 11,000 oscillations per minute (opm)

- Weight: 3.6 pounds

Pros

- Lightweight with ergonomic grip

- Rapid charging

- High capacity 5-Ah battery

Cons

- Challenging to control vertically

- Expensive

Best Wood Chisels

REXBETI 10pc Premium Wood Chisel Set

See ItEven woodworkers who largely use power tools can benefit from a good set of general-purpose wood chisels. They are invaluable for cleaning up after machining or fitting joints and hinges. The six chisels in the REXBETI set range from ¼- to 1½-inch, providing solutions for a wide range of tasks.

Blades are made from chrome vanadium steel, which keeps its edge well. Sharpening chisels is often seen as a skill that takes time and patience to acquire, but a precise honing guide and stone are included, making the job quick and easy. Ergonomic handles provide good grip and have striking buttons on the end so use of a mallet will not damage them. The Rexbeti wood chisel set also includes a pair of carpenter’s pencils and comes in a smart storage case.

Product Specs

- Power: Hand or mallet

- Material: Chrome vanadium steel

- Weight: 5.8 pounds

Pros

- Variety of chisels included

- Chrome vanadium steel blades

- Ergonomic handles

Cons

- Not always sharp on arrival

- Traditionalists prefer wooden handles

Best Bench Grinder

Delta 8-in Grinder Model

See ItThe Delta 8-inch bench grinder is one of those tools that woodworkers wonder if they need, then wonder how they did without. Bench grinders are not just great for sharpening chisels and blades for hand planes and other tools; by changing one of the wheels, it can also be a polishing station.

Variable speed, which is changed from a dial on the front, makes it easy to adjust to different tasks. The supplied wheels are 36 grit and 60 grit, which are fine for general grinding and sharpening tasks. We would recommend a 100-grit wheel for use on quality wood chisels and wood-turning tools.

Guides can be something of a disappointment on bench grinders, but these have good adjustability, allowing precise angles to be set for sharpening. Shields are provided for safety, and a flexible lamp brightens the work area.

Product Specs

- Power: Corded, 5 amps

- Speed: 2,000 to 3,400 rpm

- Weight: 44 pounds

Pros

- Powerful and reliable variable-speed motor

- Guides offer good adjustment

- Flexible work light

Cons

- Supplied wheels are average quality and wear quickly

- Finer wheel required for quality chisels

Best Dust Collector

SHOP FOX W1727 1 HP Dust Collector

See ItSawdust is bad for the respiratory system, ruins finishes, and can be a fire hazard. If there’s static in the air, it may even explode. A shop vac is one way of keeping the woodshop clean, but a dedicated dust collector like the Shop Fox is much better.

The powerful motor and 9-inch impeller blade provide suction of up to 800 cfm (cubic feet per minute). Sawdust is drawn into an upper bag that filters particles down to 2.5 microns (as fine as the protection offered by N95 face masks). Waste then drops into the lower bag for collection and disposal. The Shop Fox dust collector can be attached to a single machine, used as a central unit for a small workshop and, thanks to the wheeled base, can be easily moved around as required.

Product Specs

- Power: Corded, 9 amps

- Height: 54 inches

- Weight: 55 pounds

Pros

- Suction power of 800 cfm

- Filters particles down to 2.5 microns

- Waste capacity of 2.1 cubic feet

Cons

- Casters are low quality

- Fitting lower bag is finicky

Our Verdict

The DEWALT Sliding Compound Miter Saw is superbly made, versatile, and has excellent capacities. Add the SKIL Corded Jig Saw to a workshop for sheet working and cutting curves. Every woodworker needs a drill driver, and again it’s a DeWalt that is our top pick. It is one of the best combinations of power and value currently available.

How We Chose the Best Woodworking Tools

I am an engineer, a DIY enthusiast, and for 11 years ran a woodworking shop. I have a thorough understanding of how these tools work and hands-on experience using them. Extensive product research has also been conducted to ensure up-to-date information.

Usually we compare a range of similar tools for these helpful guides. In this case, each tool is different. Nevertheless, many of the criteria remain the same.

First, we looked at top performers. While specifications can be impressive, we were also careful to consider cost. Some of the best woodworking tools are simply too expensive for most home users. They might also be too large for all but commercial workshops.

Brand reputation also has a major impact. Names like Bosch, DeWalt, Makita, and SKIL have long been recognized for build quality, and each makes an appearance in our list. However, we were also careful to look at sub-premium brands (though most are still household names). In doing so, we believe we have offered the widest possible choice, with tools for woodworkers at different stages of learning and with different budgets.

FAQs

In the article above, we have discussed some of the key aspects of the best woodworking tools and provided a selection of high-quality examples. While this information will have answered many of the questions that arise about adding woodworking tools to a shop, there are a few popular questions of a general nature that we have answered below.

Q. How many tools do I need for my woodworking projects?

It very much depends on the project, though many can be accomplished with fewer than you might expect. A lot can be done with just a saw, a drill, and a screwdriver. With a half dozen well-chosen woodworking tools, you can potentially make hundreds of different items.

Q. Do woodworking tools need to be maintained and cleaned from time to time?

Absolutely. Cleaning and maintaining your tools stops rust, prevents damage, makes woodworking tools and machinery more pleasant to use, and increases their working life. It is seldom hard work, and it doesn’t take very long if done regularly.

Q. When is the time to replace my woodworking tools?

When they no longer perform as originally intended; they cannot be repaired economically; and the performance is impacting accuracy, speed, ease of use or safety, it is usually time to replace the tools.

Q. What tools are not that essential for woodworking?

What’s not essential is different for every woodworker. Some will seldom use a router, while others will find it indispensable. Some will never use a hand plane. Others feel that using a hand plane is a real test of a carpenter’s skill. Focus first on the type of woodworking you want to begin with, and build a tool set that fits your needs and budget. Anything else is not essential unless your needs change.