We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Pipe Clamp

Woodcraft

A pipe clamp is often used in cabinet or furniture construction for edge gluing wood together. It can be made to any size by simply changing the length of pipe between the fittings. The pressure exerted by a pipe clamp can mar wood, so it’s a good idea to protect the wood being clamped with blocks, cardboard, or felt.

C-Clamp

Ace Hardware

One of the most widely used and most versatile clamps, the C-clamp is generally made of steel or cast iron. It comes in a variety of sizes and is operated by turning a threaded rod that closes the “C” when tightened. You can easily overtighten a C-clamp, so take care not to damage softer woods—sandwich your work between blocks of wood, or buffer it with cardboard or felt.

Spring Clamp

Rockler

Spring clamps work much like clothespins, but with greater force and stability. They come in many sizes, which are rated by the width of the opening. They are useful in so many applications, not only in the shop, but throughout the house as well. Because they’re some of the cheapest clamps to purchase, you can afford to have several in every size.

Handscrew Clamp

Lumberjocks

A handscrew clamp consists of two hardwood jaws and two handles with long threaded screws. This clamp’s greatest advantage is that it can be adjusted for various odd shapes and angles. It distributes pressure evenly over the hardwood jaws, so it is less likely to damage or mar the wood it’s holding.

Ratcheting Bar Clamp

Wayfair

A bar clamp is similar in construction to a pipe clamp, but it’s outfitted with a ratcheting handle that slowly draws the jaws together, so it can be operated with one hand. The handle also has a quick release, making the clamp a snap to remove.

Ratcheting Band Clamp

Fine Woodworking

A band clamp is an excellent choice for situations where multiple surfaces, particularly those that aren’t parallel, need to be clamped together, or where clamping pressure needs to come from multiple directions. Special band clamps, through which you can thread corner blocks, can be used to clamp a mitered frame or box. The band clamp is also great to use for circular pieces.

Toggle Clamp

StrongHandTools

A toggle clamp can be attached to a work surface or a jig to keep a piece of work stationary while it’s being machined. Toggle clamps come in several sizes and in differing varieties—push, pull, and right-angle—all tailored to specific circumstances. Pushing the handle down forces an adjusting screw onto the work to keep it immobilized.

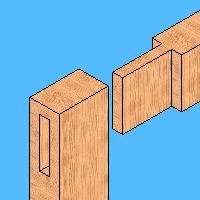

Corner Clamp

Corner clamps help you make corners or T-joints by holding your pieces in place while you work. Smaller sizes are used for jobs like pictures frames, larger sizes for something like a bookcase. They don’t apply force, so they don’t actually push two pieces of wood against each other. Rather, they frame and hold your pieces so you can glue and screw them together. Buy them in pairs.

For More…

Core77

If you are interested in more about tools, consider: