We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Whether you’re a rookie handyman or a seasoned do-it-yourselfer, a range of basic tools is essential to doing the small jobs around the house. Pick a place for your cache of tools—a kitchen drawer, maybe, a carton in the hall closet, or even a real toolbox—and make a point of always returning the ones you use to their designated home.

What tools will you need? Your skills and the kinds of jobs you do must be your guide, but a good basic selection would include a tape measure, square, and torpedo level for measuring and setting. A handsaw or handheld circular saw; a utility knife; a cordless drill; and maybe a glass cutter will take care of your cutting and drilling tasks. For fastening, how about a small set of screwdrivers; a staple gun; pairs of electrician’s, waterpump, and locking pliers; and a hammer?

You can take it from there. Add what you need, like chisels, a sander, and some clamps, and supplies, too, like sandpaper, nails, glue, screws, and so on. Don’t necessarily tool up all at once—that could feel expensive—but do buy tools of good quality rather than the cheap and flimsy ones on sale. Better tools last and last, and get you through many jobs, those you do both for recreation and in an emergency.

Tape Measure

Few tools translate to so many trades, from dressmaking to dressing stone—the convenient and compact tape measure makes all kinds of jobs possible.

Also called a push-pull tape, the basic tape measure is spring loaded so that the tape retracts into its metal or plastic case when not in use. It comes in all sorts of sizes, from 3-foot key-chain sized rules to bulky 25-foot flexible rules.

Tape measures have blades (as the tapes themselves are officially known) that come in 1/2-inch, 3/4-inch, and 1-inch widths. Wider tapes are bulkier, but also have the advantage of extending farther without the supporting hand of an assistant at the other end. A good size for most around-the-house jobs is a 3/4-inch-wide, 16-foot-long tape measure.

Combination Square

As with any square, the principle job of a combination square is to advise its user when the relationship of two sides of an object is a true 90-degree angle.

The combination square is adjustable, consisting of a rigid steel rule, typically 12 inches long, with a headpiece that slides along its length. The headpiece has both a 90-degree edge and one that forms a 45-degree angle with respect to the rule. It’s ideal for marking (and checking) both 90-degree crosscuts and miter cuts.

The combination square can be used to determine the squareness of a piece or joint or as a saw guide when using a handheld circular saw. When the head is set at the end of the rule, the combination square can measure heights; and it can be adjusted to measure depths. It’s very handy for marking, and there’s even a bubble level in its handle, enabling the tool to be used for leveling.

Torpedo Level

Usually 9 inches long and tapered at both ends, this handy tool is also known as a canoe or boat-shaped level. Inside the plastic, wood, or metal body of the torpedo level are two or three spirit tubes.

These sealed vials contain water, alcohol, or another clear liquid. Each tube or vial is slightly curved with two parallel lines drawn at its center. The vial is not quite full, leaving space for an all-important air bubble. The bubble vial has been precisely mounted so that when the bubble is aligned between the hairlines, it indicates that the body of the level, and thus the object being trued, is at true vertical or horizontal, depending upon how the vial in mounted in the level.

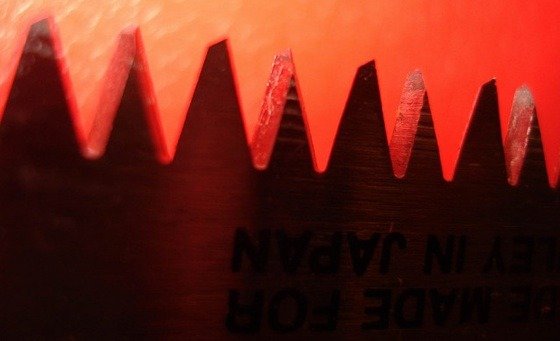

Handsaws

Even in this age of power tools, the traditional handsaw has many uses. It’s quiet, portable, easy to use, requires no electrical power, and can finish more than a few jobs the basic hand-held circular saw cannot. It’s also inexpensive and poses little risk to little hands.

The basic handsaw has a blade roughly two feel long that tapers from the heel (at the handle) to its toe. The most common use is simple cut-off work when it’s quicker to grab a handsaw than it is to run an extension cord to do the job with a power saw.

Approach a handsaw as if to shake hands, grabbing its closed wood or plastic handle. The flat blade, typically of steel, will flex from side to side. The teeth may be designed for cutting across the grain (crosscut saws) or for cutting with it (ripsaws). A 10- or 12-tooth crosscut saw of 22 inches is a good basic saw that can also rip a board if necessary.

Electric Drill

This is one versatile tool—it will drill holes, sand and grind, stir paint, and drive screws and good basic electric drills start at a very modest price.

The basic electric drill consists of a motor built into a pistol-shaped body. Instead of a gun barrel, though, there’s a gripping device called a chuck into which one of a wide variety of bits or drill are inserted. Older models lock the bits in place using a key that tightens the chuck, but most new drills use a keyless chuck that requires only the grip of your hand to tighten it. It’s a good innovation, that makes changing bits much quicker and easier.

Another recent shift is to cordless drills. The initial cost is significantly is higher, but for the extra money there’s a big jump in convenience. It’s a judgment call, but if the price doesn’t seem prohibitive, the gain in flexibility is probably worth the extra investment.

Claw Hammer

When most people think of a hammer, the image of a claw hammer comes to mind. The head has a face that is used to drive nails; on the opposite side of the head is a two-pronged claw that is used to pull nails out of wood. The head is steel, the handle can be of fiberglass, wood (typically hickory), or steel. Fiberglass and steel hammers usually have rubber, plastic, or vinyl handles for a sure grip and shock absorption.

The claw hammer may be the carpenter’s most essential tool, but not all hammers are the same. They range in size from small tack hammers to huge framing hammers that are 18 inches long and weight almost two pounds. For most people, a good general purpose hammer is moderate in size, weighing perhaps 16 ounces with a 16-inch handle. The heads vary greatly, too, with flattened or curved claws. Chose a smaller hammer for finer work; go larger if you plan to drive large nails.

Screwdrivers

Most screwdrivers share an overall design, consisting of a steel shaft called a shank, a tip called a blade, and a handle. But there are lots of variations in blades and handles, not to mention the oddball screwdrivers that have no shafts at all but instead use ratchets offset at a 90-degree angle to the tip to drive screws in confined spaces.

Most handles are bulb-shaped, large enough to be gripped comfortably in the palm of the hand. Electrician’s screwdrivers usually have plastic handles—the plastic insulates the user from the risk of electric shock. Wooden-handled drivers are more often found in woodshops. Auto mechanics tend to favor drivers that have rubber sleeves on the handles for a firm grip. Drivers can be long or short, ranging from stubbies about 2-1/2 inches long to specialty drivers 2 feet or more.

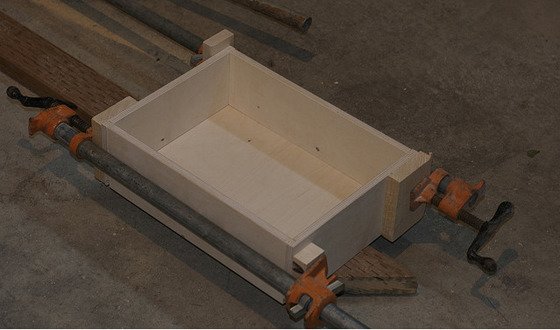

C-Clamps and Bar Clamps

The clamp is a simple tool, consisting of a pair of jaws drawn together with a tightening mechanism, typically a screw drive. When working with wood in particular, a clamp is essential for pulling together the pieces to be glued and for holding them tight and flush until the glue sets.

While there are lots of types of clamps, for most around-the-house jobs, C-clamps or bar clamps will do the work. C-clamps have jaws in the shape of the letter C, with metal shoes at the top and bottom to grip the work piece. Bar clamps are usually larger, with a fixed jaw at one end of the bar and another on a tail slide that moves up or down its length. The pressure is exerted by both C-clamps and bar clamps by the screwdrive, typically driven by a T bar that forms a handle.

A recent variation on the traditional bar clamp is the quick-grip clamp. These rely on a pistol-squeeze action. Quick-grips don’t have the same clamping power as bar clamps but have cushioned jaws and are easier to use.

Random Orbital Sander

A convenient, one-handed tool, the random orbital sander is driven by an electric motor. The motor spins a shaft on which a counterweight is mounted. The combination of the weight, the spinning shaft, and an offset thrust bearing produces a random, varying motion. Which is to say, it spins and wiggles, never the same way twice, and does a neat job, producing little or no scratching across the grain. The motion also tends to clean the sandpaper, avoiding the clogged surfaces common to straight-line sanders.

The random orbital sander uses prefabricated sandpaper disks, available from coarse to fine, which will remove lots of material quickly or produce a fine finish. Depending upon the manufacturers, the sandpaper is attached with either hook-and-loop (Velcro) or pressure sensitive (adhesive) backings.

Random orbital sanders are sold as single-speed and variable-speed models. Most come with a dustbag attachment, which also reduces the frequency with which the dust clogs the paper and results in a somewhat cleaner work area.

Staple Gun

The staple gun can be used to fasten all kinds of materials in home construction and maintenance work. Roofing contractors, insulation installers, carpenters, and all kinds of homeowners and hobbyists find a multitude of uses for staplers every day.

The staple gun is no more than the larger, tougher sibling of the desk stapler that’s a fixture in every office. The ammunition is bigger, as most guns take staples that are 1/4 inch to 9/16 inch long; the width of the staples varies with the manufacturer.

Staple guns come in hand-powered and electric models. The most common variety is powered by a spring: a large lever built into the handle at the top acts as trigger, and the spring squeezes out a staple when the gun is pressed into the workpiece. Electric models are faster and easier to use; another type, the hammer stapler is swung like a hammer. It’s great for construction jobs but not for delicate ones.

Locking Pliers

These adjustable pliers are useful as a hand-held vice or clamp. They lock firmly onto a workpiece, usually one of metal. They are also known as plier wrenches, lever-wrench pliers and by the proprietary name Vicegrips.

The key is the double-lever action of the jaws. Like other pliers, the jaws of the locking pliers are closed by squeezing the handles together; unlike water pumps, electrician’s, and other pliers, the jaw opening is adjusted by turning a screw drive in one handle so the jaws will close with a vice-like grip. A trigger on the other handle loosens the grip, which can apply tremendous force.

Locking pliers are sold in several designs (with long nose, flat-jawed, and even C-clamp jaws), but the standard design has serrated, straight jaws. A pair in the eight- to ten-inch long range will have the most uses in the basic toolbox.

Bevel Gauge

Though the bevel gauge is a near relation of the square, its purpose is to help fabricate pieces that are not square.

The tool consists of a handle (or stock) with an attached tongue (or blade). The tongue fits into a groove cut into the head of the stock where it’s fastened with a locking mechanism. Often the tongue is made of thin steel and the stock of wood, plastic, or metal.

To put the tool to use, hold the stock against an edge with the tongue stretched across the workpiece. The tongue can then be shifted to assume any angle between zero and 180 degrees. When the bevel gauge is set at the angle you want, use the bolt and wing nut or lever device to set the tool at the desired angle.

This is one of those wonderful tools that belies its simple design. It makes some difficult tasks easy to do well, such as matching an existing angle. You set the gauge then simply move the bevel gauge onto the stock from which you’ll be making the companion piece. There’s no geometry or arithmetic, just marking and cutting.

Carpenter’s Square

The carpenter’s square isn’t a four-sided figure. It’s really a giant L, usually with a 2-inch-wide, 24-inch-long leg perpendicular to a 1-1/2-inch-wide, 16-inch-long tongue.

The most common use, as one of its nicknames suggests, is for framing, laying out and marking patterns for framing, roofing, and stairway work. It’s also useful as a straightedge for determining the flatness of surface, and for marking cutoff work on wide stock. Call it almost anything you like—including rafter square, builder’s square, or roofer’s square — but this is a tool that has lots of uses.

The calibrations on the face of a carpenter’s square will include dimensions, usually down to eighths of an inches, but sometimes on the back there’ll be tens or even twelfths of an inch for roofing layout.

Plumb Bob

The plumb bob or plumb line employs the laws of gravity to establish what is “plumb” (exactly vertical). You don’t need a graduate degree in physics to understand that a string suspended with a weight at the bottom will be both precisely vertical AND perpendicular to any level plane through which it passes. The plumb bob, obviously, is the companion tool to the level.

A homemade plumb can consist of most any bit of string with a weight tied its end (a couple of washers, say, or a lead sinker from a fishing line. But the factory-made plumb bob has a specially designed weight and coarse string of twisted cotton or nylon threads (masons prefer the nylon because it stands up better over time to the dampness that comes with working with water and mortar). Well-machined and well-balanced bobs have pointed tips, too, that make them more precise to use.

Handheld Circular Saw

With the possible exception of the electric drill, the Skilsaw® or circular handsaw is the power tool most often found in the average homeowner’s tool chest. It’s easy to use, affordable, and astonishingly flexible and practical.

It’s designed to cut boards to size, typically using a 7-1/4-inch-diameter blade. An electric motor, protected in a housing, drives the blade that is, in turn, protected by a fixed guard on top and retractable guard below. Add a handle, a sole plate or shoe on the bottom, and you’ve got all the parts. Plug it in and go.

One warning, though: This is no toy. It’s a powerful and efficient tool, but one that poses a real danger if not used with respect and care. Keep it well out of reach of the under-18 set.