We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

The jigsaw resembles the band saw in that the workpiece is presented to the blade atop a small table (nine inches by seventeen is about average; some brands have larger tables). Curved workpieces can be done on both the jigsaw and band saw, but that’s where the resemblance ends.

Also called the power scroll saw, the jigsaw differs in several significant ways from the band saw. For one, the blade is not continuous, but rather is short and straight, cutting in a reciprocating (up-and-down) motion. More important, the jigsaw cuts more slowly than a band saw and with very much less power; it’s used to cut quite intricate shapes. Most models have variable speed controls.

As with the band saw, the depth of the throat determines the flexibility of the tool; sixteen inches is a practical size, though models with smaller and larger throats are sold. A depth of cut of an inch and half is common, but one- and two-inch maximums are found on smaller and larger models.

A variety of jigsaw blades are available, with the teeth per inch ranging from as few as seven to twenty-five or more. Most are jeweler’s blades, which are five inches long, between one-twentieth of an inch and a quarter inch wide. Others are blades designed for use on a saber saw.

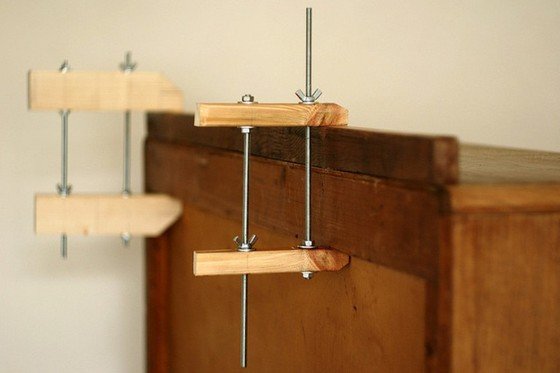

Jeweler’s blades are fastened at top and bottom in clamps, with the teeth facing forward and pointing down. Saber-saw blades are installed in the lower chuck only, with the point of the blade directed upward.

On most saws, the blade can be turned, so work can be presented to it from the front or the side of the saw. Different blades are designed for different tasks, but one or another will cut just about any wood, metal, or plastic. Some tiny ones are sold, as small as one one-hundredth of an inch thick and only about two one-hundredths wide. They are perfect for delicate marquetry work.

The blade used for a given task must be suited to the material to be cut: Finer-toothed blades are appropriate for metal and hardwoods, coarser blades for softwoods.

The speed at which the saw cycles is another consideration. Slower speeds are best suited to cutting metal, faster ones for softwood. It may seem odd at first, but cutting plastic is done at slower speeds (too much blade speed will actually melt the plastic, allowing it to weld together again after the blade passes through). Hardwood will also heat up if the speed is too fast. Speeds of up to about seven hundred and fifty strokes per minute are regarded as slow, while fifteen hundred or more strokes per minute is fast. Not all models come with variable speed controls; on some, as on certain drill presses, the drive belt is shifted from one set of pulleys to another.

The jigsaw also has a holddown device which acts very much like the adjustable foot on a sewing machine, holding the work down (without it, the up-and-down motion of the saw tends to lift the workpiece). The worktable on most models tilts up to forty-five degrees for bevel cuts. Most models have stands available, and some are sold with vacuum attachments and with sawdust blowers to keep the cutting area free of debris.

Cutting Curves with the Jigsaw. This is the jigsaw’s forte. Even so, a little thinking ahead will enable the saw to do the best possible job. For complex cuts full of twists and turns, drill turning holes at the tightest corners to enable the blade to make the turn without straining (and possibly breaking) the blade. This will also ensure a more regular cut.

Use the holddown, and feed the stock at a measured pace. The jigsaw doesn’t race through wood like a circular saw: Take special care to keep the blade from bending or twisting.

Internal Cuts. These are cuts in which the opening being sawn is entirely within the perimeter of the workpiece. You’ll need to cut a hole through the waste area inside the piece, and fit the jigsaw blade through it (after first disconnecting the blade from the upper chuck). An easier method is to use a saber-saw blade. Drill the starter hole first, then lower the piece over the blade.