We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

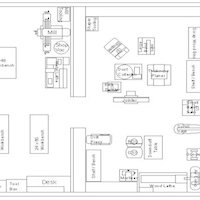

Consider some of these issues as you’re planning your woodworking shop.

Doorways. Standard household doors are often as narrow as thirty-two or thirty-four inches; in a shop, a minimum of thirty-six inches is more like it. Wider, even double doors make moving in machinery and stock and moving out millwork easier.

Stairways. As wide as possible is the rule when planning your woodworking shop: certainly no less than thirty-six inches (if you have any choice), and forty-two inches is better yet. The steps should, ideally, fit the standard formula, being not too steep (risers more than eight inches tall tend to be a bit trippy). Wide treads of ten or more inches make carrying tools, materials, and finished work a bit less hazardous.

Ventilation. If you need a ventilation fan (and you will if you do any spray painting or much finishing work), here’s the formula for determining the size you need. Calculate the number of cubic feet in your shop (width times length times height), then divide by four (e.g. a 10-foot-wide x 20-foot-long x 8-foot-tall space = 1,600, divided by 4 = 400 cubic feet). Many standard kitchen exhaust fans will move some 400 cubic feet of air per minute (CFM), but larger fans are available for larger spaces.

Be sure if you ever use contact cement, solvents, or other materials that produce flammable fumes that the fan is equipped with an enclosed motor.

Heating and Cooling. When planning your woodworking shop, remember it should be not too cold, but also not too hot. Somewhere in the sixty- to sixty-five-degree range is probably best (warmer is not ideal, because you want to work with some protection and perspiration will tempt you to shed the safety gear).

In a cellar, a nearby furnace will probably suffice. A small space heater is an option in a space that is warmed to some degree by another source. An electric baseboard heater is relatively inexpensive and easy to install but expensive to run for long periods. Some models come with a built-in thermostat, others require a separate wall-mounted control.

In other spaces, you may need to provide another source of heat. A traditional one is a woodstove, an especially efficient approach in cold-climate woodshops. The supply of fuel in a woodshop usually keeps pace with the need (when you’re at work on a project, the scrap provides you with heating BTUs; when you’re not at work, you don’t need to heat the place anyway). Woodstoves require special precautions. When spray painting, or using strippers or other chemicals with flammable fumes, be especially careful with the stove and use an exhaust fan. You may want to heat the shop first, let the fire die, then do your work.

Be vigilant about keeping the vicinity of the stove clean. Sawing, sanding, and other tasks launch sawdust into the air. A little sawdust and a hot coal that escaped the stove undetected spell instant danger. Be sure to follow the local fire codes when installing a stove (clearances below, beneath, and behind the stove, as well as spark protection in front of any openings). Make sure you have proper fireproof materials or insulation around the stove fittings. A proper chimney may be most important of all.