We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

An electric drill without bits is like a bow without arrows. And the better the bit (or arrow, I suppose), the better the result.

Like sawblades, drill bits come in lots of flavors, suited to drill through just about anything. Depending upon your needs, you’ll probably want to have several different types on hand, but a good starter set of drill bits should include at least a small index (perhaps ten drills) of twist drills and a set of spade bits (perhaps six pieces).

Twist Drills. Twist drills were invented by a fellow named Morse, and some machine shop types refer to a twist drill as a Morse drill. A twist drill has a cylindrical steel shank and a pointed tip. A pair of helical flutes (sometimes called chip channels) run along two-thirds of its length, twisted around the shank like the stripes on a barber’s pole.

The cutting edge (called the lip) is at the tip where the mouths of the flutes meet the workpiece. the flutes themselves do no drilling, but clear the debris from the hole to prevent the drill from binding or being slowed by the waste.

The tips on most twist drills are ground at a 59-degree angle to the shaft so that they will cut metal efficiently; naturally, they’ll cut wood, too. Carbon steel bits are ground specifically for drilling wood and should not be used to cut metal. Twist drills are commonly sold in sizes ranging from a sixteenth of an inch up to half-inch diameters. Most twist drills larger than a quarter inch have reduced shanks of a quarter inch.

Spade Bits. These bits look like their name suggests: Each steel shaft terminates in a spade-shaped blade. The spade is flat, with a sharp point at the center. The point acts as a guide, centering the hole and leading the way, but the bulk of the drilling is actually done by the honed cutting edge at the shoulder of the spade.

Don’t try to cut metal with this one. Spade bits are for wood, plywood, and some plastics, and cut quickly with surprising precision. Use them only at high speeds, to prevent the bit from catching in the workpiece and the drill from trying to wrench itself from your grasp. Spade bits are found in the range between quarter inch in diameter to one and a half inches.

Brad Point Drills. Designed specifically for cutting wood, brad point drills are a cross between spade bits and twist drills. The shaft of the drill resembles the twist drill, with fluted chip channels spiraling around the shaft. Most of the cutting is done at the lips of the channels, but the hole is actually started with a smaller-diameter brad point (or spur) that leads the shaft into the hole. Two other spurs at the outer edge of the drill help keep the drill on line. The channels are usually cut deeper on brad point drills that on twist drills, in order to clean out the wood debris.

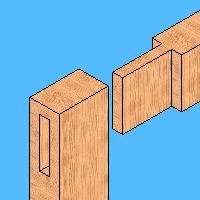

Countersink Drills. Specially made bits are sold that drill pilot holes for wood screws. Countersink drills have profiles to match the shape of the screws: The holes they drill taper gradually along the length of the screw, then enlarge, allowing the heads of the screws to be set (countersunk) into the wood.

Some countersink drills can be purchased with adjustable stop collars that can be set to halt the drill’s progress at a fixed depth. Another variety of drill, called a plug cutter, can also be purchased. It is used to cut small plugs from the same wood; the plugs can then be inserted into the screw holes after the screws have been sunk in order to camouflage their presence.

Hole Saws. The hole saw bit consists of two parts, the mandrel and the blade. The mandrel is a shaft to which the blade is attached; the mandrel is gripped by the chuck of the drill like the shaft of any other bit. The blade is a hollow cylinder with teeth on its top edge.

Hole saws handle the work in the gray area between the smaller holes best made with twist or spade bits (those roughly an inch in diameter and smaller) and larger ones (three or four inches and up) that are sawn most easily with a saber saw. Hole saws cut wood, plastics, and a variety of metals, including iron, steel, and aluminum. Hole saws are invaluable when installing piping, tubing, conduit, and cables.

Forstner Bits. These clever bits drill holes with virtually flat bottoms. Rather than having a steeply ground tip that is followed by angled cutting edges, the Forstner bit is guided by the rim. Channels in the drill clear the hole of chips and dust. The resulting hole has a virtually flat bottom, marred only by a 1/32-inch hole at center where the starter spur of the drill is located.

Forstner bits are relatively expensive, and they aren’t necessary for most jobs. However, they are essential for others, like mounting hinges that must be recessed into a round hole that extends only partway through the door stile. (If you were to use a spade bit for the same purpose, its point would probably protrude through to the other side, marring the surface.)

Masonry Bits. These are designed for drilling concrete, brick, stone, plaster, and other masonry materials that would quickly dull or fracture most drills. A masonry bit has an enlarged tip of tungsten carbide that is attached to a steel shaft.

These bits are used to cut relatively small holes (typically three-quarter-inch or less) in masonry, either to run cables or piping through, or for mounting plugs or shields for attaching shelves or other materials to the masonry.

Masonry bits should be driven at relatively slow speeds to prevent them from overheating. Periodically withdraw the bit from the hole as you drill, to remove loose dust and debris.

Other Drills. Among other options are corner bits (they resemble spade bits, but the sides as well as the face of the drill are sharpened); glass bits; and mixing bits, large and small, for paint, plaster, and other liquids.