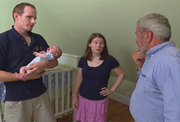

Hi, I'm Bob Vila, welcome to the show and our remodeling project here, where were making a couple of rooms ready for a brand new baby in a two-family house outside of Boston.

Today we're going to be showing you some nice new windows from Pella that include some very safe types of window shades.

Also, we're installing a toilet, and in the master bathroom we're going to be putting in some paneling, as well as some new type of tile.

Stick around.

It's good to have you with us.

Today, we're back at our nursery project here in Melrose, Massachusetts.

Our 1895 two-family house and last week we insulated the roof of the third floor, and Nick and Maggie, the homeowners, gave us a tour of their apartment, second and third floor, where they're pretty busy making some changes and remodeling , getting ready for their first baby, who's arrival is quite imminent.

And today we're going to look at an important feature of the nursery which has to do with windows and window shades, we've got Cordel Burton here from Pella, hey Cordel.

Hi Bob.

So, the big news here Cordel is that the window shape is sandwiched in between panes of glass, right?

That's right.

It's right inside the two panes of glass.

And they're all interchangeable so if you want to change from one color to another it's easy to do?

That's right yes.

And of course the good news is that you don't have to worry about cords which can be a real danger to a youngster, getting caught in the crib or even with toddlers and stuff.

It actually goes from out here, you adjust it from the outside.

Okay, and the top sash?

And the top sash, we have the shades already in side.

We've been putting in some room-darkening shades.

So that's a darkening on, and of course you could always flip it out and change that one as well, what kind of color selection have you got?

actually, if they have a little baby girl we do have pink so.

Pinks and blues and all sorts of options there.

That's nice.

That's a nice blue.

So they've chosen a nice color that goes with the

Nice neutral color.

You know what I like as well, you're not gonna have any dust catchers here.

That's right, there's actually 200 times less allergens on these shades than there are on a normal shade or blind.

'Cause they're trapped behind the glass.

What about the actual efficiency of the window in terms of the weather.

Yeah, you've actually got a full-insulated panel on the outside, plus another paint so they are far more efficient than the normal typical window.

For cold and for sound.

And for sound.

That's right.

Now, Cordell, is this an easy installation for the average do-it-yourselfer.

Yes, actually it's quite simple.

Most of the typical homeowners could do this by themselves.

So how do you go about it with an old window that you've got to get out of there and stuff?

With an old double hung window, the first thing you got to think about is just removing the old stops and as you remove the stops the sash will actually come out as well.

Right, so you've got the inside stop and the parting bead or...

Parting stop.

Yeah.

Yeah, and then so if you remove those the sash come out.

Right.

That leaves a nice open pocket for the new window to go inside of.

The sill of the window quite often can be damaged.

So we come up with a new smart flash tape, it's a butyl based tape that you can actually use to protect areas at the bottom of the window opening.

What about, you know, old double hung sash, there's pockets for the weights in there and that's usually a big source of energy loss

That's right.

It's a big old pocket in the side.

What we used here today is actually a foam that we just blow in the side of that pocket and it'll expand and fill most of that up.

So, it's an easy do-it-yourself job?

Yes.

Thanks Cordel.

And downstairs, our homeowner, Nick has dealt with a different kind of installation.

We've finished our roofs, which then allowed us move on to our framing.

We re-framed the floor, leveling it, and taking care of some of the structural damage that the previous plumbers had done.

We were able to then do the rest of our framing in the bathroom to define the new master bath, which is off the bedroom and on the other side of this wall is the powder room.

On this wall, we were able to install our cementitious board to accept tile.

We got our tub in.

And our new tub deck, and we got our cement board down on the floor too for the tile.

and then when we took the plaster down on the exterior wall we realized that we didn't have... it was under framed for what it should have been.

There were no headers or anything and the windows, which were mismatched because they were originally in two different bathrooms.

Thought this was a good time to just, re-do the whole thing.

Make it structurally sound and also put in some matching windows that would be more centered on the space.

So, to re-frame the wall for the new windows we wanted the space between the windows to match and so, although this looks like a big structural support, it's actually really just acting as a big spacer.

Up above we had to put in a new header, which we made out of two, two by eights and in between the two by eights we put a piece of half-inch plywood, which is just, again, actually this space there's not really structural, but that way our dimension of the two two by eighths and the half inch is three and a half inches which is the same dimension as a two by four.

So, now we're ready to install the windows.

So, to make sure the installation is water tight we followed the recommendations of the window manufacturer which we're using Pella windows in this case.

So, we start with a cut down the middle, stopping close to the bottom.

A couple angle cuts down to the corners, then we cut straight across the top.

and this allows us to fold everything back.

It creates a nice water proofing.

And we just staple it back keep it out of our way.

And then we trim the excess off, so it's nice and clean.

Makes it easier to work with.

Next, the manufacturer recommends that we basically make a water pan out of a water proof tape.

It's self adhesive, so we cut it .

They recommend going about 6 inches up on each side.

Maybe you installed it.

This kind of tape it's always really important that you get the corners nice and tight, because you can end up with a fair amount of build up, which can create problems later on when you try to fit your window.

So we double it up so we make sure that we get the complete window sill covered, and let it overhang about an inch, so we can cover the, get all the way beyond the opening, that way if there is any water that does manage to get in or we get any condensation build-up around the window, it will get, it'll flow to the outside and not affect our framing.

So it's important whenever your doing waterproof projects like this that you work from the bottom up, because if you think like a drop of water, The water's going to run down the sides and then into the bottom.

And so you want to make sure that if it runs down, it overlaps the bottom piece instead of running behind the bottom piece.

Before we hand the window out the opening, I'd like to get it all set by bending back the nailing flange.

Got it?

Get the bottom out, there we go.

You're okay?

With the window roughed in place we make sure it's nice and level and plumb, and then we As per the manufacturer's recommendation, we shim it in three spots on the bottom, in the middle and the top, and we do that before we nail off flange.

To make sure that it's, it won't move once we start nailing.

One more.

Now we check one more time.

Still looks good.

Alright, John, nail it.

In order to make an air tight seal, Pella provided us with some spray foam insulation.

We'll just run around and fill all the voids around the window.

So this is low expansion window and door foam.

And it's important that you use low expansion foam when you're doing windows and doors because, if the foam expands too much it can push your jams out of plum, or out of level.

And then your door and window won't operate correctly.