We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Ask any seasoned carpenter or DIYer what tools take up the most room in their toolbox, and the answer is probably “screwdrivers.” While there are a few types that are more common around the house than others, like the flathead and Phillips, there are plenty of others used in home improvement and many carpenters have different go-to favorites.

Unlike other building standards, there is no single universal screwhead that is suitable for use in framing, decking, or woodworking, so it’s imperative to have a variety of screwdriver types and screwdriver heads (bits) ready to insert or remove any type of screw you may come across. Plus, you’ll also probably find the need for both manual and powered screwdrivers for around-the-house maintenance and woodworking projects.

If you’re just getting started equipping your toolbox, pay close attention to the following different screwdriver types. More than just outfitting your toolbox for future projects, it’s way easier to find the right driver for a screw when you know the name of the shape.

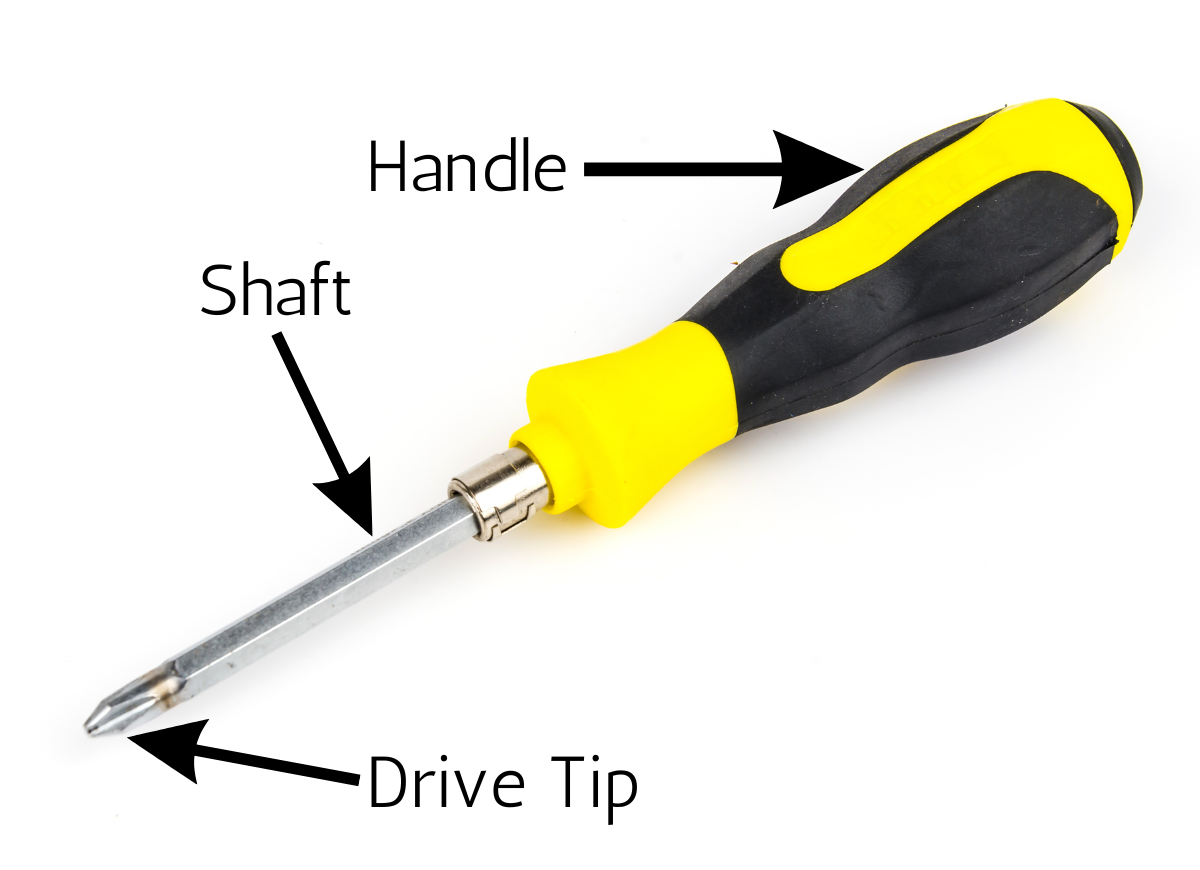

Screwdriver Parts

Before diving too deeply into the different types of screwdrivers, it’s important to recognize these tools’ parts. In fact, it’s typically one or two of these parts that differentiate one screwdriver from the other.

Screwdrivers are generally made up of three parts: the handle, the shaft or shank, and the drive tip or bit.

- The handle is the part of the screwdriver that the user holds and twists. While some may be wood or carbon fiber, they’re generally a hard plastic or nylon and some feature rubber grips.

- The shaft or shank is the long section that connects the tip to the handle. These are generally smooth and polished for easy cleaning, but some may be hexagonal or partially hexagonal to allow the user to place a wrench on the shaft. They vary in length from stubby (under 2 inches) to very long (over 12 inches).

- The drive tip or bit is arguably the most important part of the screwdriver as it determines which fasteners the screwdriver can engage to tighten or loosen. Common screwdriver bits include slotted, Phillips, Pozidriv, Torx, square, star, security or tamper-proof bits, and hex or Allen bits.

RELATED: Buyer’s Guide: The Best Screwdriver Sets We Tested This Year

Types of Screwdrivers

There are many different types of screwdrivers made for a variety of uses. The following includes some of the most common (and not so common) screwdrivers that DIYers and pros might want to add to their collections.

1. Flathead (or Slotted Head) Screwdriver

While flathead screws and screwdrivers aren’t used extensively in residential construction anymore, you’ll need them to remove or install plate covers on outlets and switches and in other instances where it’s important not to over-tighten a screw. You also can still find them in furniture construction and small cabinet-making projects.

Flathead screwdriver bits are available for ratcheting screwdrivers and drills, but it’s also a good idea to keep a handful of flat manual screwdrivers in your tool bag. They’ll come labeled by both the size of the tip and the length of the steel shank. Tip sizes vary, from fractions of millimeters (which are tiny enough to tighten eyeglass screws) up to an inch or larger (fit for industrial-size screws). When matching a slotted screwdriver to a flat screw, pick one that matches the width and depth of the slot on the screw head in question. (One request, though: Please don’t use your flathead screwdriver to pry lids off paint cans because you can damage the can lid. A better tool for that is a painter’s multitool.)

Best For: Electrical cover applications and some woodworking and cabinet-making scenarios where overtightening could split wood

Our Recommendation: Craftsman 5-piece Slotted Screwdriver Set — Get it on Amazon for $18.78

This 5-piece kit comes with varying sizes of screwdrivers that will fit the most common slotted screws a DIYer is likely to encounter around the house.

2. Phillips Screwdriver

Phillips screws, identifiable by a flared “+” on their heads, are widely used for construction and woodworking purposes. The screwdrivers and bits that fit Phillips screws are labeled “Ph,” followed by a number ranging in increasing size from 0000 up to the number 4. The drivers are numbered differently than the Phillips screw sizes, so it is usually easiest to physically match the driver tip to the specific screw.

A manual or ratcheting screwdriver works fine for when you have just one or two screws to install, but construction projects notoriously use a number of screws. Opt for a power drill or impact driver with interchangeable Phillips bits for the most efficient build.

Best For: General purpose fastening, assembly, and repairs

Our Recommendation: Greenlee 0153-33C Heavy Duty Phillips Screwdriver — Get it on Amazon for $12.87

Greenlee’s 0153-033C screwdriver has a soft cushioned grip, and durable construction, and it features a #2 Phillips tip that fits screws 5, 6, 7, 8, and 9 is helpful for general use.

RELATED: How to Use a Phillips Head Screwdriver

3. Pozidriv Screwdriver

A Pozidriv screwdriver is essentially a new-and-improved version of the Phillips screwdriver. These bits have the same self-centering Phillips recesses with the addition of a blade between the wings of the Phillips bit. These blades fit into the notches in the recess of a Pozidriv screw, providing more surface area and preventing slipping when applying greater torque, like when using an impact driver or drill fitted with a Pozidriv bit.

Pozidriv screws aren’t overly common, but they can be used in any situation that a Phillips screw can be used. The most common use is heavy-duty construction screws, but they can be used for woodworking and common repairs, too. Keep in mind that it is possible to remove a Pozidriv screw with a Phillips bit, but it’s best to use a Pozidriv for the best nonslip results. For active DIYers and pros, a Pozidriv set is a good addition to a tool kit.

Best For: Heavy-duty construction screws and anywhere a Phillips screw could be used

Our Recommendation: Vessel Ball Grip Interchangeable Screwdriver — Get it on Amazon for $13.00

Vessel’s Ball Grip Interchangeable Screwdriver comes with three interchangeable bits, two of which are Pozidriv bits (#2 and #3), providing the DIYer with plenty of flexibility.

4. Robertson (or Square) Screwdriver

The Robertson screw offers the distinct advantage of reduced screwdriver slippage. Also known as the “square recess screw,” this screw head was developed in the early 1900s by a Canadian inventor who was tired of damaging slotted screws every time the screwdriver tip slipped out of the slot. Though a great improvement, it didn’t catch on in the U.S. until power drills began being used in place of screwdrivers.

Today, the Robertson screw, which commonly comes in sizes 0, 1, 2, and 3, is used in construction and remodeling projects but is most popular in cabinetry and pocket hole joinery. You can find manual and ratcheting square recess screwdrivers, but the Robertson screw is most often inserted and removed using a power drill. One of the most common uses for the Robertson screw is in the installation of subflooring, which goes a lot quicker if you use a power drill and a Robertson screw bit.

Best For: Construction, remodeling, cabinetry, pocket hole joinery

Our Recommendation: Picquic’s Robertson Bit Set — Get it on Amazon for $12.49

Picquic’s Robertson Bit Set comes with four sizes, including the most commonly needed #2.

5. Torx (or Star) Screwdriver

Quickly becoming a favorite of builders and serious DIYers, the Torx screw—sometimes called the star drive screw—features a 6-point recessed star tip in sizes that range from 0.031” to 0.81,” and are designated by “T” numbers (from T1 to T100). Common building sizes are T15 and T25 and, whatever the screw size, there’s a corresponding Torx screwdriver or screwdriver bit to fit.

Manual and ratcheting Torx screwdrivers are available, but power drill users like Torx screws for the same reason they like Robertson screws: They resist slippage during applications that require serious power. Torx screws are typically used for structural framing, finish work, and as wood-to-concrete fasteners. They’re also popular in automotive and bicycling applications.

Best For: DIY, structural framing, finish work, wood-to-concrete scenarios, automotive, bicycling

Our Recommendation: Wera 05028062001 Kraftform Plus 367/6 Torx Screwdriver Set — Get it on Amazon for $33.05

This kit from Wera comes with six of the most common Torx screwdriver sizes and features a comfortable, ergonomic grip that also resists rolling.

6. Hexagon (Hex) Screwdriver

Hex-head screws are typically small and commonly found in doorknobs, towel bars, faucet handles, and even some mechanical installations. They require a hex key screwdriver (also called an Allen screwdriver, Allen key, or Allen wrench) to tighten or loosen. Other uses for this tool include working on cars and bicycles, and assembling some types of flat-packed furniture.

Screwdrivers and bits range in size to fit hex-head screw recesses from around 0.03-inch to ⅜-inch wide. Allen-type screwdrivers, or wrenches, are often L- or T-shaped manual screwdrivers, although Allen bits are available for both ratcheting screwdrivers and drills. Some swappable bits may take the place of individual drivers, popping into and out of a ¼-inch hex driver for improved versatility.

Best For: Installing small fixtures, working on automotive or bicycle applications

Our Recommendation: Bondhus 10686 1.5-5mm Balldriver Screwdrivers, 6 Piece Set —Get it on Amazon for $19.99 and Bondhus 10632 Set of 8 Balldriver Screwdrivers — Get it on Amazon for $22.80

With both kits, DIYers will have the most frequently used small to mid-size hex screwdrivers necessary to tackle a range of projects.

7. Spanner Driver

Spanner screwdrivers have forked tips with two prongs. They’re commonly used for hardware in tamper-proof situations such as fire alarms, commercial door hardware, and electronic devices that have a code or for devices that the manufacturer deems should stay shut. These screws have two small recesses in their heads, preventing any traditional screwdriver from successfully opening them.

The spacing of the prongs determines the size of the screw they’ll fit, and many kits come with several tips of different sizes. It’s important not to overtighten these screws as the tips of a spanner driver can snap off relatively easily.

Best For: Alarm devices, electronic devices

Our Recommendation: Rannb Spanner Screwdriver Set — Get it on Amazon for $11.99

Rannb’s Spanner Screwdriver Set has screwdrivers in five sizes with magnetic tips for ultimate tamperproof screw control.

8. Frearson Driver

Frearson drivers, also called Reed and Prince drivers, are common in the marine and boating industry. At first glance these screwdrivers look very similar to Phillips bits, but they’re slightly different. The recesses in Frearson screws come to a sharp point, and the blades of the Frearson drive match that point. Also, the inside angles of the cross pattern of a Frearson bit are much sharper, allowing for more surface area during tightening (if a Frearson drive is used, of course).

These bits are most common in the marine industry. They can handle a large amount of torque before stripping, which is critical for boatbuilders fastening hardwood timbers. Outside of the marine industry, however, these screws and their drivers are rare.

Best For: Boatbuilding, marine industry

Our Recommendation: Bosch FR2102 Extra Hard Frearson Bit — Get it on Amazon for $5.39

Bosch’s FR2102 bits fit in a ¼-inch drive socket or nut driver, allowing DIYers to keep a Frearson bit on hand without investing in an entire screwdriver kit.

9. Japanese Industrial Standard (JIS) Screwdriver

DIYers and home mechanics who enjoy working on Japanese motorcycles or vintage cars might be aware of the JIS screwdriver, but very few others are. These screwdrivers fit JIS screws, which are essentially shallower versions of the Phillips screw, with sharper angles and more surface area.

The JIS screwdriver design prevents JIS screws from camming out-–the driver slipping out of the screw head—when applying a lot of torque. However, it can frustrate folks who aren’t aware they exist. Using a Phillips screwdriver on a JIS screw will likely result in stripping. But, most JIS screws are easily identified by a small dimple to one side of the slot.

Best For: Working on Japanese machinery, like motorcycles or cars

Our Recommendation: Vessel Armor Grip 8-piece Set — Get it on Amazon for $29.99

Vessel’s Armor Grip set comes with JIS-ready bits for Japanese Industrial Standard screws.

10. Jewelers’ Screwdriver

Jeweler’s screwdrivers, also called precision screwdrivers, are small screwdrivers designed for working with very small fasteners. They typically feature all-metal construction with a wide cap on top. This cap spins, allowing the user to set a fingertip on top to steady the screwdriver while manipulating the screwdriver with the thumb and middle finger. This allows for careful control when working with tiny screws.

Jewelers’ screwdrivers aren’t just for jewelry. They can also be helpful in watchmaking and repairs, as well as their most common DIY use: Repairing and tightening eyeglass hardware.

Best For: DIY jewelry making, watch repairs, eyeglass repairs

Our Recommendation: SATA 15-Piece Master Precision Screwdriver Set — Get it on Amazon for $31.99

This kit from SATA includes 15 of the most common precision screwdriver sizes necessary for DIYers, watchmakers, and jewelers.

11. Computer Screwdriver

Computer screwdrivers are essentially the same as jewelers’ or precision screwdrivers. They feature the same spinning cap that the user places their fingertip on, allowing them to steady the screwdriver while fastening tiny screws that hold hardware, memory cards, and other important items in laptops and computer towers.

These screwdrivers can double as eyeglass repair tools and watchmaking kits. They can also repair electronic devices other than computers, such as TVs, remote controls, and even a smartphone (for those brave enough to crack theirs open). What generally separates these screwdrivers from jeweler’s kits is the comfortable plastic or rubber handle.

Best For: Computer and electronic repairs

Our Recommendation: EasyTime 140-in-1 Precision Screwdriver Set — Get it on Amazon for $20.99

The EasyTime kit comes with 140 pieces that allow users to work on a wide variety of electronics, including video game controllers, TV remotes, computers, and more.

12. Precision Screwdriver

Precision screwdriver kits are similar to jewelers’ and computer screwdrivers. They’re designed for working on small hardware such as those in watches, electronics, jewelry, and other scenarios where the hardware is too small to use a full-size screwdriver.

There are two main types of precision screwdrivers: all metal and those with plastic or rubberized handles. Both feature the spinning cap on the butt of the handle that allows the user to hold the screwdriver in place and spin it without slipping.

Best For: Electronics, jewelry, watches, tiny hardware

Our Recommendation: Fertoriy 24-in-1 Precision Screwdriver Set — Get it on Amazon for $6.19

The 24-in-1 precision screwdriver kit from Fertoriy comes with an all-metal body and swappable tips for most precision screws.

13. Tri-Angle Driver

Tri-angle screwdrivers feature a three-sided tip that fits into a triangular recess in the top of a screw. These screws are most common in security or tamper-proof situations, such as alarm devices and sprinkler system switches.

These screws don’t offer a ton of surface area so screwdrivers can slip under a lot of torque. However, these odd-shaped screws are very effective at keeping folks out of places they shouldn’t be, unless they have a triangle screwdriver.

Best For: Fire alarm, security, and tamper-proof screws

Our Recommendation: Olirexd 4PCS 16CM Triangle Magnetic Tip Screwdriver Kit — Get it on Amazon for $9.99

The Olirexd kit comes with four magnetic screwdrivers, with triangle sizes 1.8, 2, 2.3, and 3.0 millimeters for common triangle screws.

14. Tri-Wing Screwdriver

Tri-wing screwdrivers are another common form of security driver bit. These screwdrivers look similar to Phillips drivers but have three blades instead of four. Also, the blades (the wings) are slightly offset and do not meet in the middle.

These screwdrivers are common in the aerospace field. Many screws and bolts used to assemble aircraft and their parts are tri-wing. They’ve also been used on Apple and Microsoft products, as they offer a bit more security than a Phillips screw.

Best For: Aerospace applications and some Apple and Microsoft devices

Our Recommendation: Octoder Triwing Screwdriver Kit — Get it on Amazon for $9.99

The Octoder Triwing Screwdriver Kit offers three precision-style screwdrivers with silicone handles at a very reasonable price.

15. Clutch Head (or Bow Tie) Screwdriver

Clutch head screwdrivers feature bow tie-shaped tips that fit in security-type screws. Like the spanner, triangle, and tri-wing screwdrivers, these screwdrivers are used on devices that have a code or the manufacturer requires to stay closed. This could be an alarm device or an electronic device.

Clutch head screws are generally a one-way type of screw. Their heads are designed to grab a slotted screwdriver blade in the clockwise direction (tighten), but allow the tip to slip in the clockwise (loosen) direction. Clutch head screwdrivers are able to grab these screws, however, in either direction.

Best For: Security and alarm devices, removing one-way screws

Our Recommendation: PICQUIC 95010 Clutch Set — Get it on Amazon for $11.99

Picquic’s 4-piece set of clutch screwdriver bits come in four sizes and fit into ¼-inch drive screwdrivers.

Styles of Screwdrivers

Screwdrivers have only two purposes: to insert screws and to remove them. While types of screwdrivers are defined by tips that match the specific design of specific screw heads, you’ll find additional variations in how screwdrivers operate. These design differences often dictate which style is chosen as the best method for working with screws in a given project.

16. Manual Screwdriver

Manual screwdrivers, the hand tool’s most recognizable variation, consist of a thick handle and a cylindrical steel shank that ends in the working tip of the screwdriver. In some cases, the tip features an interchangeable bit in order to match a number of screw head patterns and sizes. Because the handle is larger than the tip, it takes only moderate twisting force to turn a screw.

When using a manual screwdriver, you may have to lift the screwdriver from the screw head after every turn of the screw and reposition it before the next turn. As you grow more accustomed to screwdrivers, you’ll be able to hold the butt of the screwdriver in your palm and twist the screwdriver with your thumb and index and middle fingers instead of lifting it out of the screw.

Best For: Situations where screws shouldn’t be overtightened, one-off fastening, copper or brass hardware, small screws

Our Recommendation: Klein Tools 32500 11-in-1 Screwdriver / Nut Driver Set — Get it on Amazon for $14.97

This manual screwdriver from Klein has 8 bit tips and 3 different nut driver sizes, giving users a versatile tool that can handle most screwdriving situations.

17. Electric Screwdriver

Some power tool manufacturers have improved on the standard drill by manufacturing designated power screwdrivers, or screw-insertion tools geared to specific applications. These machines have powerful electric motors attached to transmissions and clutches, allowing users to easily drive screws into a variety of materials. This allows for improved production and reduced fatigue.

There are several job-specific electric screwdrivers. Drywall screw guns, for example, are used only for hanging drywall, while subflooring screw guns work specifically with collated screw coils.

Best For: Repetitive fastening

Our Recommendation: DeWalt Drywall Screw Gun — Get it on Amazon for $89.98

DeWalt’s Drywall Screw Gun features a 5,300-rpm high-speed motor and will release the bit from the screw at the correct depth.

18. Impact Screwdriver

Impact screwdrivers are all about applying a ton of torque very quickly, mainly to break a heavy-duty bolt loose. These tools have thick metal bodies with gears inside. As the user strikes the butt of the impact screwdriver with a hammer, the gears force the swappable bit in the end to rotate, cracking the bolt or screw loose. The sudden force both onto the bolt and rotationally resists stripping.

Impact screwdrivers aren’t commonly used for anything other than breaking a stubborn screw or bolt loose. Once the fastener is free, the user can switch to a standard tool to remove it.

Best For: Breaking stubborn bolts and screws loose

Our Recommendation: Tekton 3/8-inch Drive Impact Screwdriver — Get it on Amazon for $19.39

Tekton’s ⅜-inch drive impact screwdriver kit comes with four bits and a swappable square drive socket.

RELATED: How to Remove a Stripped Screw

19. Insulated Screwdriver

Insulated screwdrivers are standard screwdrivers that are made with materials that protect the user from electrical shock. They’re most commonly used by electricians, HVAC technicians, and other folks who regularly work around live voltage.

Insulated screwdrivers come in most tip styles, though slotted and Phillips are the most common. These screwdrivers are generally expensive, and although they’ll fit standard screws, DIYers often save them for electrical applications (though we suggest never working around live wires).

Best For: Electrical applications

Our Recommendation: Klein Tools 85076INS Insulated Screwdriver Set on Amazon for $39.97

The Klein Tools Insulated Screwdriver Kit comes with six screwdrivers in the most common sizes used in electrical work.

20. Right Angle Screwdriver

Right angle screwdrivers are screw guns with straight handles and a head that bends at 90 degrees toward the end. This allows the screw gun to maintain a lower profile between wall studs and floor joists, where a full-size drill or screw gun would not fit with a bit attached.

Some right angle screw guns have opposable heads that allow the user to adjust the angle of the head for easier fastening. These tools come in two varieties: light-duty and heavy-duty. Light-duty is ideal for small screws, while heavy-duty right angle drills are designed for drilling large holes in framing lumber.

Best For: Fastening screws when clearance is an issue

Our Recommendation: BOSCH PS11-102 12V Max 3/8 In. Right Angle Drill/Driver Kit — Get it on Amazon for $134.00

Bosch’s PS11-102 12V drill/driver features an opposable head that clicks into five positions for comfortable fastening.

21. Cordless Screwdriver

With the advent of the drill and the ability to swap drill bits for screwdriver bits, the converted screwdriver drill was born. Powered drill/screwdrivers greatly reduce the time it takes to insert or remove screws, which are swiftly replacing nails in many building and remodeling projects thanks to the strong hold in wood that their ribbed sides provide.

Cordless screwdrivers come in many forms, from lightweight drivers to full-size screw guns. The choice is largely based on a matter of preference. However, large screw guns can often be overkill for smaller fasteners, and light-duty screwdrivers won’t be as versatile.

Best For: Repetitive fastening where a power cord would get in the way

Our Recommendation: Bosch PS21-2A 12V Max 2-Speed Pocket Driver Kit — Get it on Amazon for $99.00

Bosch’s PS21-2A 12V Max Pocket Driver features two batteries and a powerful motor in a compact tool.

RELATED: Buyer’s Guide: The Best Screwdriver Bit Sets

22. Magnetic Screwdriver

There are few things as frustrating as trying to install a screw into a hole only to have it slip off and fall on the ground. Manufacturers combat this frustration by crafting magnetic screwdrivers. These drivers have magnets built in that cling to the screw, allowing the user to place it into the hole without it falling off.

Magnetic screwdrivers can be a big boost to productivity for those working with small parts or under the hood of a car. When these items fall off and go missing, it slows the entire work day. Instead, a magnetic screwdriver holds the screw or bolt firmly in place.

Best For: Working with small parts, automotive applications

Our Recommendation: Klein Tools 32500MAG Magnetic Multi-Bit Screwdriver — Get it on Amazon for $20.97

Klein’s Magnetic Multi-Bit Screwdriver features 11 different driver bits, all magnetized, in one tool.

RELATED: How to Magnetize a Screwdriver

23. Bolster Screwdriver

Bolster drivers refer to a style of screwdriver shaft, not a driver tip. These screwdrivers have hex-shaped bolsters at the base of the shaft (where it meets the handle). The bolster serves two purposes: it keeps the shaft from driving up into the handle in heavy-duty scenarios, and it also allows the user to place a wrench over the bolster to increase torque.

Bolster drivers come in a variety of driver types, but larger #3 Phillips and ¼-inch slotted are the most common.

Best For: Heavy-duty applications in which additional torque is required

Our Recommendation: Wiha 5-Piece Slotted and Phillips Screwdrivers — Get it on Amazon for $53.20

This 5-piece set of bolstered screwdrivers includes both slotted and Phillips styles, and features comfortable grips with heavy-duty bolsters.

24. Ratcheting Screwdriver

Ratcheting screwdrivers save time and reduce the need to lift and reposition the screwdriver tip after every turn. This saves a DIYer time, but also reduces the wear and tear on the screw or bolt. An internal ball-bearing mechanism allows the user to make multiple turns of the screw through an easy back-and-forth wrist action. One direction twists the screw while the other ratchets back to allow the user to apply force again.

The ratcheting action works both tightening and loosening. Users can change the direction from one way to the other by switching a button on the screwdriver, so that a DIYer can both insert screws (clockwise motion) and remove screws (counter-clockwise motion) with the same ratcheting function. This can go a long way to preventing fatigue and producing productivity.

Best For: Repetitive fastening

Our Recommendation: Wera Kraftform Kompakt 27 RA Slotted Ratcheting Screwdriver — Get it on Amazon for $43.23

Wera’s Kraftform Kompakt screwdriver allows users to switch between clockwise and counterclockwise ratcheting with the twist of a collar, and it comes with multiple driver bits.

RELATED: Buyer’s Guide: The Best Hand Tools We Tested This Year

25. Spiral Ratchet (or Yankee) Screwdriver

One specific ratcheting screwdriver called a Yankee screwdriver (also called Push Pull drivers) operates on a spring-loaded ratcheting principle. In addition to using wrist action to turn the screwdriver, users can simply position the tip of a Yankee screwdriver in the screw head and push firmly toward the screw. The pressure causes the screwdriver shank to turn; when released, the tension spring inside pushes the handle back to its starting position.

Yankee screwdrivers have been around since the late 1800s, but you can still find them in DIY stores. They do take some getting used to, but they can be very handy when tightening long screws or bolts. The tips are usually swappable, and they can be used to drill holes in a variety of materials

Best For: Tightening long screws or bolts or drilling holes without a drill

Our Recommendation: Eazypower 83635 8 Piece 9½ to 12″ Push Pull Click Screwdriver with Drill Bit Kit — Get it on Amazon for $42.99

The Eazypower kit comes with several bits and allows users to choose between push-pull fastening or basic ratcheting.

Final Thoughts

There are many types and styles of screwdrivers, and there is no one-size-fits-all tool for every project (though an 11-in-1 might be close). Because there is no standard fastener for home improvement projects, no handy DIY tool kit is complete without a variety of screwdrivers. Luckily, adding a screwdriver or two to the kit shouldn’t break the bank.

Prices listed here are accurate as of February 22, 2023.