Ace Hardware Is Clearing Out DeWalt Tools for Free Ahead of Spring

Buy a DeWalt 60V string trimmer kit or 20V trimmer and blower combo and choose a free pruning saw, hedge trimmer, or pruner valued up to $179.

Buy a DeWalt 60V string trimmer kit or 20V trimmer and blower combo and choose a free pruning saw, hedge trimmer, or pruner valued up to $179.

Soak, dab, and gently clean away dirt and stains with inexpensive upholstery cleaners you can make at home.

This inexpensive household multitasker repels insects, removes rust, and cleans everything from coffee makers to laundry.

Meet PureGuard, Lawnbright's new natural perimeter pest control, and save 25% through March 30.

My biggest takeaway? It’s not impossible to take on an exterior renovation in winter with the proper preparation.

Eager to get a head start on gardening by planting seeds indoors? Learn which seeds are best for early sowing—and when to do it.

These trusty tools traverse floors, kitchen crevices, and other zones we shudder to think about. When was the last time you gave your broom a bath?

The EGO Power+ 56V trimmer and blower combo kit is now $249 (was $349), giving homeowners a battery-powered way to tackle edging and leaf cleanup before peak lawn season begins.

Amazon marked down several Bosch 18V tools, including a compact drill/driver kit with two batteries for $134. Sanding, grinding, and cutting tools are also seeing big price drops.

Bosch doesn’t run freebie promotions often. This Lowe’s deal lets shoppers add a CORE18V battery kit and choose a free pro-grade tool valued at up to $179.

Starting seeds indoors gives gardeners a jump on the summer growing season. Speed up the germination process with the right seedling heat mat.

You can grab a DeWalt drill and impact kit for $139, a Milwaukee multi-tool for $99, and brushless options from Bosch and Craftsman—all priced under $200. See our favorites.

Before you remove old paint or renovate an older home, use a home lead test kit to check if lead is present in your walls and other surfaces.

From a $144 chaise lounge set (was $674) to half-off propane fire pit tables and smokers under $200, these backyard deals deliver serious savings just in time for outdoor season. See our favorites.

Make artful and practical use of garden waste with linear creations that also provide an important ecological link, creating nutrient-rich homes for microorganisms and animals.

Experts want you to avoid storing these common items in the attic to ensure they don’t get ruined or forgotten.

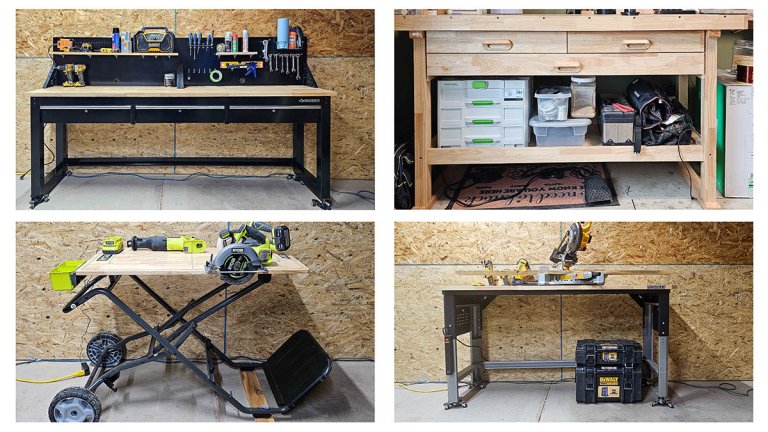

From weekend projects to pro-level builds, these workbenches provide the space and stability you need.

Increase kitchen functionality at any hour with extra output from easy-to-install under-cabinet lighting.

Get the lowdown on drill bits so you’ll know which ones to buy and rely on for all kinds of drilling tasks and DIY projects.

Add an essential tool to your workshop without overspending.