We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

It’s hard to beat the look of hardwood flooring. But, solid hardwood flooring can be expensive, and it’s not always the best choice for use in humid conditions.

Alternatively, engineered wood flooring uses boards that are made of layers of wood that form a stable core that is less likely to expand and contract when exposed to fluctuating temperatures and humidity. This makes engineered hardwood floors a good pick for basements or rooms with radiant heating systems in the floor. Keep reading to learn more about the best engineered wood flooring.

- BEST OVERALL: Heritage Mill Oak Harvest Engineered Click Hardwood

- RUNNER UP: Bellawood Red Oak Engineered Hardwood Flooring

- BEST VALUE: Malibu Wide Plank French Oak Rincon Hardwood Flooring

- UPGRADE PICK: Bellawood Select Maple Engineered Hardwood Flooring

- BEST WIDE PLANK: Bellawood Willow Manor Oak Engineered Hardwood

- BEST TRADITIONAL: Heritage Mill Red Oak Natural Engineered Hardwood

What to Consider When Choosing the Best Engineered Wood Flooring

When installed properly, engineered wood flooring looks just like genuine, solid hardwood. Choosing the best engineered wood flooring takes some consideration, and there’s a bit to know. The following points will explain some of the most important considerations to keep in mind when shopping for this flexible flooring option.

One of the most important points to understand is that engineered wood flooring consists of a hardwood veneer on top of a core layer of other woods.

Veneer Wear Layer and Finish

Unlike solid hardwood, engineered wood floors have a veneer wear layer at the top portion of the flooring. It’s the part on which you walk, play, drop stuff, and put your furniture. The veneer is hardwood, so you can get engineered wood flooring in the same colors and species as solid hardwood flooring. The best engineered hardwood floors come in oak, maple, mahogany, bamboo, and more.

There’s a great degree of variance between products when it comes to the veneer layer’s thickness. Some products feature thin wear layers (often less than 1 millimeter thick), while others offer 2-, 3-, 4-, or 6-millimeter veneers. The thicker veneer products can be refinished if damaged.

Some of the best engineered wood flooring takes durability to another level with a protective finish that’s made of a naturally occurring compound called aluminum oxide. These products are more durable and harder to scratch than engineered wood without an aluminum oxide finish, but they usually cannot be refinished.

Core Layers

The core layer is the material that the veneer sits upon. Manufacturers make core layers from a variety of materials. Higher-quality products typically use a plywood core, with seven to 11 layers of wood. These layers are called plys. The more plys in an engineered wood floor, the less likely it is to cup, shrink, split, or expand. Simply put, the thicker the flooring, the longer it will last.

Some engineered wood flooring has HDF (high-density fiberboard) cores. They’re often much more affordable than a plywood engineered wood floor. These cores are stable, but they soak up moisture like a sponge.

Finally, there are also softwood core layers, made up of strips of softwood (typically aspen). The strips run perpendicular to the veneer, helping to resist cupping, shrinking, and splitting.

Dimensions and Installation Options

Engineered wood flooring comes in a variety of widths from traditional sizes in the 4-inch range to farmhouse-style boards that are 7 inches wide or more. Most engineered hardwood floors are around 5 inches wide, a size that is less susceptible to cupping than wider boards. There are design considerations for choosing a width as well. Narrow engineered wood planks give a room a formal or contemporary feel, while wider planks give a room a country, a colonial, or an old-world aesthetic.

Most engineered wood flooring comes in random-length planks to give the installation a more hand-built look.

The proper way to install engineered hardwood flooring varies based on the product. Some engineered wood floors need nailing or adhesive to stay in place, while others can float on top of an existing floor. Unlike solid hardwood, floating floors have click-in systems that hold the entire floor together. The installation method is less a sign of quality than it is a preference. There are high- and low-quality options in both varieties.

Maintenance

Maintaining the best engineered wood flooring is no different than maintaining a solid hardwood floor. The veneer layer is hardwood, after all. You can use a wood floor cleaner, vacuum, and/or wax them with the same products you use for solid hardwood floors.

DIYers can even refinish engineered wood floors that have a veneer layer that is thicker than 2 millimeters and without the aluminum oxide overcoat. Scratches in the veneer can be sanded, and then a fresh coat of wax or other sealing product can be applied to refinish the floor.

One thing to consider is moisture resistance. While engineered wood floors are often mistaken for laminate floors, engineered wood floors are not as water resistant as laminate. Engineered wood will soak up moisture and humidity just like a hardwood floor, so it’s essential to mop up moisture, water, and liquids right away before they stain the veneer.

Our Top Picks

Based on the above shopping considerations, here are the top picks for some of the best engineered wood flooring in a range of categories.

Best Overall

Heritage Mill Oak Harvest Engineered Click Hardwood

Pros

- Measures ⅜ inches thick and 4 ½ inches wide

- Protective aluminum oxide clothing

- Covers 20 square feet of flooring

- 4 finishes offered

Cons

- No water protection

- Underlayment or padding required

Product Specs

- Veneer Thickness: 2 millimeters

- Veneer Finish: Oak

- Core Layer(s): 5 layers of solid wood

- Installation Type: Lay-and-click

DIYers looking for a quality click-style engineered wood floor should check out Heritage Mill’s Oak Harvest Engineered Click Hardwood Flooring. This flooring measures ⅜-inch thick and 4¼ inches wide, and it comes in random lengths to look like real wood floors.

The veneer layer of this flooring is prefinished oak that’s 2 millimeters thick. There is also a protective coating of aluminum oxide on the veneer to ensure the surface is as durable as possible. The core layer consists of five layers of solid wood, glued with the grain running perpendicular to each other for stability. One case covers 20 square feet of floor space.

This flooring comes in over 4 finish types including red oak, tan, natural, and oak. Installation requires a lay-and-click floating design, though gluing is also an option.

Get the Heritage Mill flooring at The Home Depot.

Runner Up

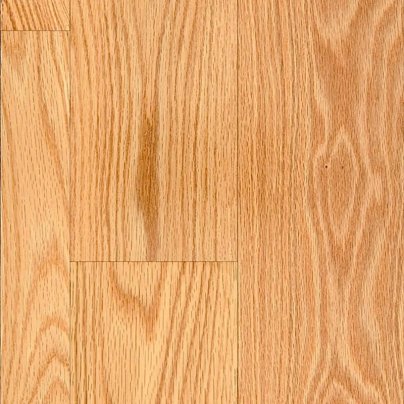

Bellawood Red Oak Engineered Hardwood Flooring

Pros

- Aluminum oxide protective layer

- Humidity- and moisture-resistant

- Irregular lengths for a solid hardwood look

Cons

- Trickier to install compared to similar products

Product Specs

- Veneer Thickness: 3 millimeters

- Veneer Finish: Red Oak

- Core Layer(s): Plywood

- Installation Type: Nailing and gluing

Bellawood’s Red Oak Engineered Hardwood Flooring features a 3-millimeter-thick veneer of red oak, giving it the traditional look of solid hardwood floors. Oak serves as the flooring industry’s benchmark for wood hardness, so it’s one of the most popular choices. Thanks to a protective layer of aluminum oxide on the veneer, this engineered oak flooring is more resistant to scratches, stains, and scuffs than solid oak flooring.

The oak veneer sits on top of a plywood core that’s resistant to humidity and moisture changes. Each plank is 5 inches wide and ½-inch thick and comes in random lengths between 12 inches and 71½ inches, mimicking the irregular lengths of solid hardwood flooring. Although this product has a tongue-and-groove design, installation requires nailing or gluing.

Get the Bellawood Red Oak flooring at LL Flooring.

Best Value

Malibu Wide Plank French Oak Rincon Hardwood Flooring

Pros

- 6 ½-inch wide planks

- Aluminum oxide protective layer

- All boards are the same length; meticulous design

- Comes in 10 finishes

Cons

- May require additional underlayment

- No water protection

Product Specs

- Veneer Thickness: 1.2 millimeters

- Veneer Finish: Oak

- Core Layer(s): High-density fiberboard

- Installation Type: Click-and-lock or gluing

For DIYers choosing engineered wood flooring to save money, this product from Malibu Wide Plank is an attractive option. This oak flooring has 6½ inch-wide planks that will give a room a premium look at a reasonable price. The oak veneers on this floor are just 1.2 millimeters thick, so they cannot be refinished. But the veneer has a tough aluminum oxide coating that will resist the scratches, stains, and scuffs that make refinishing necessary. That coating is an important feature for a thinner veneer.

Each plank in this kit is ⅜-inch thick and 47½ inches long. Since the boards are all the same length, this floor won’t have the random look that flooring in random sizes does. While installers can glue this floor down if desired, it’s designed to click together and float without issue.

Get the Malibu Wide Plank flooring at The Home Depot.

Upgrade Pick

Bellawood Select Maple Engineered Hardwood Flooring

Pros

- Can be refinished

- Planks are different lengths; provides a solid hardwood look

- Patented finish resists scuffs and damage

- Tongue-and-groove design

Cons

- May require underlayment for installation

Product Specs

- Veneer Thickness: 3 millimeters

- Veneer Finish: Maple

- Core Layer(s): Plywood

- Installation Type: Gluing and nailing

Bellawood’s Select Maple Engineered Hardwood Flooring has premium veneers of creamy maple that are 3 millimeters thick. That means this product can be refinished, giving it a lifespan and durability to rival solid hardwood flooring. The veneer sits on a solid ½-inch-thick plywood core, adding to its durability.

The planks are 5 inches wide, so this product is a good pick for those looking for a luxe farmhouse style in a room. Lengths range from 12 inches to 71.5 inches, so the installed floor will have the random look of solid wood. The floor is topped with a best-in-class patented finish that resists scuffs. Bellawood’s floor features a tongue-and-groove design, but installation requires gluing or nailing.

Get the Bellawood Maple flooring at LL Flooring.

Best Wide Plank

Bellawood Willow Manor Oak Engineered Hardwood

Pros

- Wide and long plank design

- Various finish options

- Aluminum oxide finish

- FloorScore certified

Cons

- Pad recommended for installation

Product Specs

- Veneer Thickness: 3 millimeters

- Veneer Finish: Oak

- Core Layer(s): Lumber and plywood

- Installation Type: Gluing or nailing

Certain rooms and design styles beg for wide plank floors, and Willow Manor Oak engineered wood flooring from Bellawood delivers. These flooring planks are ½-inch thick and 7½ inches wide, giving a room a rustic, rugged look. Along with wide planks, Bellawood Willow Manor Oak features longer-than-normal lengths ranging from 16 inches to 84 inches. This gives the installed floor a rugged look that’s ideal for rooms where you want a farmhouse or an old-world style.

This flooring features a veneer layer of 3-millimeter white oak over a plywood core, thick enough to be refinished. The veneer has variances in color, knots, and grain to give it character. And the clear aluminum oxide finish over the top provides durability and resistance to scuffs and scratches. Installation requires gluing or nailing.

Get the Bellawood Willow Oak flooring at LL Flooring.

Best Traditional

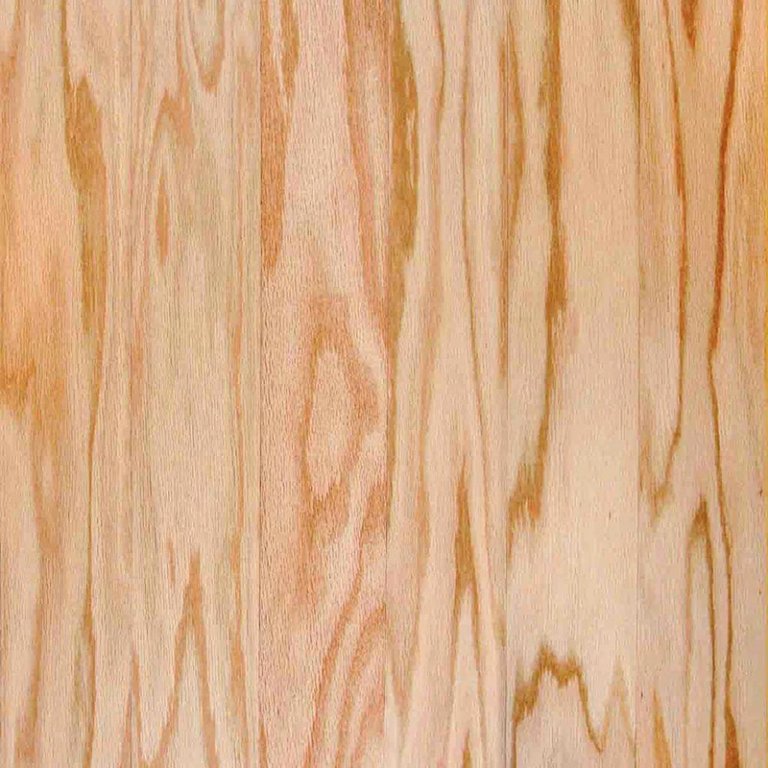

Heritage Mill Red Oak Natural Engineered Hardwood

Pros

- Real domestic hardwood construction

- Aluminum oxide finish

- Planks have random lengths; solid hardwood look

- Multiple installation methods

Cons

- No water protection

Product Specs

- Veneer Thickness: 2 millimeters

- Veneer Finish: Red Oak

- Core Layer(s): 5 layers of wood

- Installation Type: Gluing or lock-and-click

Heritage Mill’s Red Oak Natural flooring comes in 4¼-inch-wide planks that are a good pick for rooms where you want a more modern look. The veneers are made of real domestic oak hardwood that’s 2 millimeters thick with a clear finish of aluminum oxide for protection. The veneer sits atop five layers of solid wood, so this is a durable pick.

The planks are ⅜-inch thick and come in random lengths. DIYers can glue this product down, but the tongue-and-groove click design will allow for faster, glueless installations.

Get the Heritage Mill hardwood flooring at The Home Depot.

Our Verdict

For a reliable, durable engineered flooring option, consider the Heritage Mill hardwood flooring with its aluminum oxide protective layer, easy installation, and multiple finish options. Alternatively, for a budget-friendly pick, the Bellawood Red Oak flooring is moisture-resistant and the planks have irregular lengths for an authentic look.

How We Chose the Best Engineered Wood Flooring

We researched the most sought-after engineered wood floors in their respective categories and discovered that the best choices are determined by their veneer thickness and offered finishes, core layer, ease of installation, and other special features included by the top brands.

To ensure our options are versatile and last for years to come, we featured engineered wood floors with veneer wear layers of 1.2 to 3 millimeters that have an aluminum oxide coating for durability. Almost all of the options also come in multiple colorways to match your current space and have sturdy plywood, lumber, or fiberboard cores. As for how to install engineered hardwood flooring, most options come with an easy lock-and-click design or require nailing and gluing to stay in place.

Depending on the look you want for your floors, the above picks vary in plank lengths between irregular and long for an authentic, real wood floor aesthetic or a clean, modern style.

FAQs

After choosing engineered wood flooring, you may still have questions. Here are answers to commonly asked questions.

Q: Is engineered hardwood the same as laminate?

No, and this is a common misconception. Engineered wood flooring and laminate are similar in that they feature tongue-and-groove designs. They’re different in that laminate is usually made of dense fiberboard with a photo of wood grain beneath a clear plastic protective layer. Laminate doesn’t look as authentic as engineered or real wood, but it’s more affordable and more water- and scratch-resistant than engineered wood flooring.

Q: Can I refinish engineered hardwood?

Yes, you can refinish engineered wood flooring if the veneer layer is 2 millimeters thick or more and doesn’t have an aluminum oxide coating.

Q: Where should I use engineered wood flooring?

Engineered wood can be used in most any application where you would use solid wood flooring. The chief advantage of engineered wood is it can be used in places where solid wood flooring cannot, such as below-grade conditions, bathrooms, basements, and kitchens.

Q: Does engineered wood flooring scratch easily?

Engineered wood flooring scratches just like a solid hardwood floor. But engineered wood flooring coated with aluminum oxide is more scratch resistant than solid hardwood.

Q: Is engineered wood eco-friendly?

Yes. It’s much more eco-friendly than traditional hardwood flooring because each plank uses less wood. This means fewer trees were cut to make the floor so that the harvested lumber can go farther.