We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Melamine-coated particleboard is a great material for storage, basement, garage, home office, and kid’s room projects. It’s less expensive than plywood and has a much cleaner finished look than painted MDF or fiberboard. Unfortunately, the plastic resins in the coating are prone to chip when cut with a spinning saw blade. They make special (read: expensive) saw blades just for the task, but with a bit of care, you can get perfectly clean, factory-like edges with the circular or table saw blade you currently have.

This technique will also work when salvaging old particleboard furniture from secondhand stores or garage sales.

Step 1

First, measure your cut line and use a straight edge, utility knife, or box cutter to lightly score along the line on both sides of the board.

Step 2

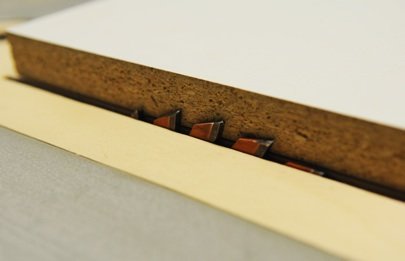

Next, set up your table saw or circular saw blade to cut 1/4″ into the material. You are not cutting through the material here; you are simply creating a clean cut in the bottom face of the melamine. Since most chips occur when the teeth that are not actually removing material come in contact with the surface, this 1/4″ deep scoring will help prevent tear-out during the final cut.

Step 3

Now, set your blade height or cut depth to just above the gullets of the blade (the standard height to prevent kickback), then…

Step 4

Turn on the saw and make your final cut.

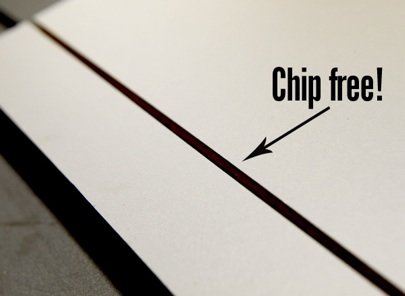

See? No chips, and no need for a special $150 laminate cutting blade.