We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

DIYers can’t get much of anything done without a good hammer. In fact, they might need several hammers, all of which could serve different purposes. They hang pictures, fasten moldings, remove nails, and much more. But is it really necessary to have five or 10 different types of hammers in a do-it-yourselfer’s tool kit?

Yes, probably.

Just about every tradesperson uses a striking tool of some sort. These tools might look and perform differently, but each type of hammer has a job to do. This guide will highlight the common types of hammers, what they can do, and who uses them.

RELATED: The Best Hammers, Tested and Reviewed

Parts of a Hammer

While the striking surface is arguably the most important part of a hammer, there are other parts you should also know about. Some of these parts have uses that can make home improvement projects and tasks around the house easier.

- The head of the hammer is the entire portion on the end of the handle. It includes the face, the claws, cheeks, and eye. It’s essentially the entire business-end of the hammer.

- The handle is the part that the user holds when using the hammer. They can be one-piece steel, wood like hickory or ash, or fiberglass. Some might have rubber grips to make swinging the hammer more comfortable.

- The claw is the part of the hammer that resembles a two-prong fork. The claw is used for removing nails, as the user can slide the claw under the head of the nail and pry it up and out of a board. They can also separate boards that are nailed together or lift heavy items off the deck slightly.

- The hammer face is the main striking surface of the hammer head. It comes in smooth or waffled configuration, with waffled faces being suitable for heavy-duty fasteners and smooth faces serving as finish and general purpose fastening.

- The neck is the portion of the hammer head that connects the face to the main head. There are hammers with longer necks meant to reach into tight areas, and those with shorter necks meant for better control.

- The eye is the hole through the hammer head that the handle sits in.

- The cheeks of the hammer head are the thin metal portions on either side of the eye. These can be used to drive nails in tight confines where the face and claw wouldn’t fit.

RELATED: How To: Use a Hammer

Common Types of Hammers

There are many different types of hammers. The following are the hammers that craftspeople and homeowners might need or use.

1. Claw Hammer

This is the kind of hammer most of us reach for when we need a hammer. The claw hammer’s steel head is dual-function: The face drives nails and the two-pronged claw pulls nails out of wood. The handle is made of fiberglass, wood (commonly a tough, springy hickory wood), or steel. Choose a fiberglass or steel option, and it will also have rubber, plastic, or vinyl handle for comfort and shock absorption.

Claw hammers can be purchased in many sizes, and the exact shape of the claw varies from one hammer to another.

- Smaller hammers that weigh a few ounces usually have claws with sharper curves.

- A moderate-sized hammer with 16-ounce head and 16-inch-long handle can perform a wide variety of tasks.

- Larger hammers that weigh up to 28 ounces often have a flattened claw, and sometimes are referred to as wrecking or rip hammers because the claw can be used to pry apart wooden elements in demolition work.

Best For: Carpentry work, general purpose projects

Our Recommendation: Estwing 16 oz. Rip Claw Hammer — Get it at Amazon for $24.88

The Estwing Rip Claw Hammer features a one-piece, forged design and a ripping claw for demolition or tearing fastened boards apart.

RELATED: For Us, This Estwing Hammer Is a Solid Hit. Find Out Why We Like It and if It’s the Hammer for You.

2. Ball Peen Hammer

Sometimes called an engineer’s hammer, the ball peen hammer is used for many metalwork tasks. Rather than having a claw, the ball peen hammer has a flat striking surface on one face and a rounded one on the other. The steel ball peen head is hardened and is less likely than a claw hammer’s to chip, making it better suited to drive punches and cold chisels, set rivets, and shape metal. Handles are usually made of hickory.

Common head weights for ball peen hammers are 4, 8, 12, and up to 32 ounces. In order to drive a cold chisel or punch, the ball peen hammer needs to have enough weight. However, a hammer that is too large can scar or distort the material (especially brass), while a smaller one will tend to shape it more efficiently. The ball peen can also be used for driving heavy nails and other tasks where its weight and hardness is an asset.

Best For: Machine work, setting rivets, and metal work

Our Recommendation: Estwing Ball Peen Hammer — Get it at Amazon for $29.98

Estwing’s Ball Peen Hammer features a do-it-all weight at 16 ounces, and its forged one-piece design is durable enough for years of work.

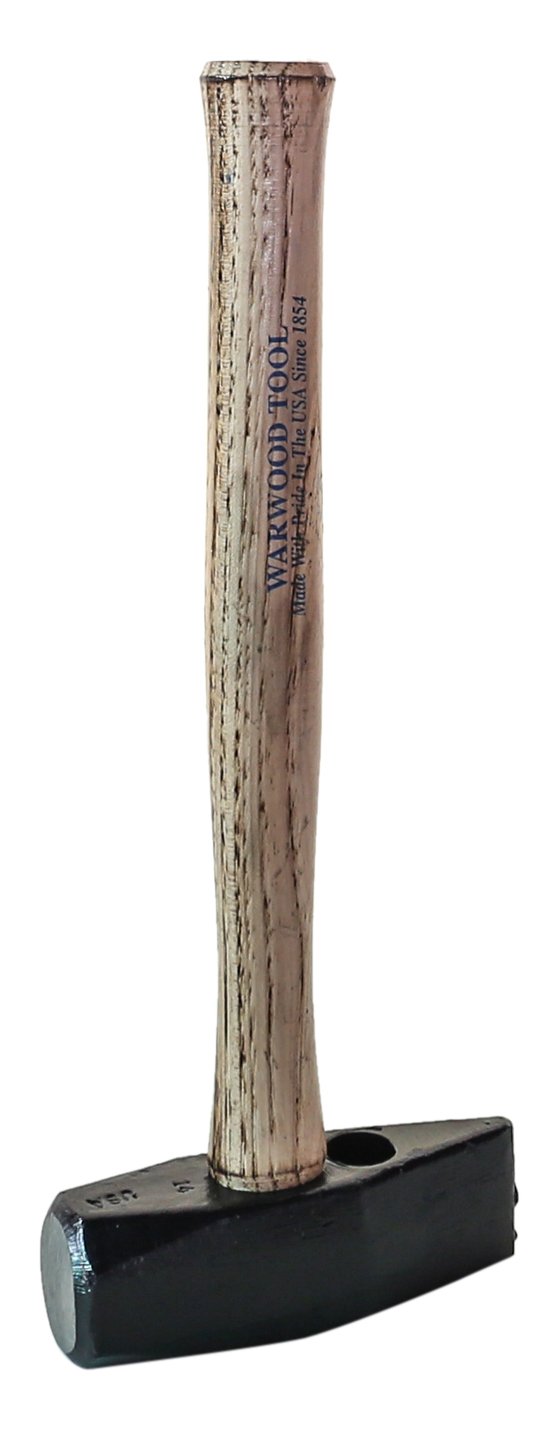

3. Club Hammer

Most club hammers have two identical faces and a short handle (typically 10 inches long). Both faces can be used, though the primary reason for the second face is that the hammer would be awkward to use if the head were not evenly balanced. Wooden handles are typically made of hickory, though fiberglass-handled club hammers are available.

The club hammer is light enough that it can be managed comfortably with one hand. A club hammer with a 2½-pound head is a useful size, though 3- and 5-pound models are also common.

Like its bigger brethren, the sledgehammers, the club hammer is used to drive stakes or cold chisels and to demolish masonry. They are sometimes called hand-drilling hammers because they are often used to drive masonry drills.

Best For: Demolition, chiseling

Our Recommendation: Stanley AntiVibe Club Hammer at Amazon for $38.45

The Stanley AntiVibe Hammer has patented AntiVibe technology to reduce vibration as well as provide a comfortable grip.

4. Dead Blow Hammer

Dead blow hammers are large, heavy tools meant for moving or adjusting an item without damaging it, such as a piece of machinery, a vehicle framing member, or any other stubborn item. They’re usually made from a polyurethane shell with loose steel shot or sand inside.

These hammers control the force used to strike the item to prevent denting and won’t bounce backward as readily. Once the strike lands on the item, the hammer’s energy stops, making it easier to control than a sledge hammer or even a ball peen hammer. They’re commonly used in maintenance and machinery applications. They come in a variety of sizes, and folks who work in these industries usually have a few options to choose from, depending on the situation.

Best For: Maintenance and machinery settings

Our Recommendation: Titan 4-pound Dead Blow Hammer — Get it at Amazon for $20.99

The Titan 4-pound dead blow hammer features a nonslip diamond grip and 4 pounds of loose steel shot for plenty of inertia without bounce-back or damage.

RELATED: The Best Tools Made in the U.S.A.

5. Electrician’s Hammer

An electrician’s hammer doesn’t look a whole lot different than a standard claw hammer, but there are some important distinctions. For one, most electrician’s hammers feature fiberglass handles. This is because fiberglass is non-conductive and should the electrician accidentally touch a live circuit, they won’t receive a dangerous shock.

The other difference is that most electrician’s hammers have longer necks. This allows them to hold a tricky staple in place with one hand and strike it with the other. They can also reach into electrical boxes or stud bays to fasten boxes. They can have curved or straight claws; electricians who choose curved claws do so because they fit in stud bays better, while those who choose straight claws like their ability to separate electrical box fasteners and other items from stud bays.

Best For: Electrical work, stapling wires, and setting boxes

Our Recommendation: Klein Tools Electrician’s Straight Claw Hammer — Get it at Amazon for $40.99

The Klein Tools electrician’s hammer features a non-conductive fiberglass handle and an extra-long neck for nailing into outlet boxes.

6. Framing Hammer

Framing hammers are long, heavy carpentry hammers designed specifically for driving framing nails into framing lumber. They generally weigh between 20 and 24 ounces (22 ounces is most common), though some titanium models are lighter but provide similar impact force. These hammers also exclusively have straight claws so they can pry framing members apart or dig into a board when picking them up. Many have handles that are more than 18 inches long, some of which are curved like axe handles (these are known as “California Framers”).

Framing hammers have large faces and short necks, allowing a carpenter to swing them hard without painstaking accuracy. Some have milled faces that bite onto the head of the nail, preventing it from slipping off, causing injury, or bending nails.

Best For: Framing

Our Recommendation: Stiletto Framing Hammer — Get it at Amazon for $90

The Stiletto Framing Hammer features a titanium head and waffled face for driving heavy-duty framing nails.

RELATED: The Best Hammers, Tested and Reviewed

7. Ripping Hammer

A ripping hammer is really any hammer that has a set of straight claws on the back. These straight claws are known as rippers, or ripping claws, and they’re used to separate boards during demolition or framing projects. They can also lift heavy items off the floor.

Lots of hammers have ripping claws. They can be general purpose hammers, those meant for precise trimwork, large framing hammers, and more. They’re handy for a wide range of projects, but they do take up more space than a curved claw hammer, so they can be a bit unwieldy in tight spaces.

It’s worth noting that some folks consider large demolition hammers to be ripping hammers. These hammers do have ripping claws, but they also have other features built in to quickly demolish surfaces and structures.

Best For: General purpose work, demolition

Our Recommendation: Vaughan & Bushnell 16 oz. Rip Hammer — Get it at Amazon for $33.50

The Vaughan & Bushnell 16-ounce Rip Hammer features a straight grain hickory handle for strength and shock absorption and a useful straight-claw design.

8. Rubber Mallet

A rubber mallet is the right tool for striking items that need to be driven but can’t withstand damage. They’re typically big, rounded chunks of rubber on the end of a wooden handle, with two wide faces. They don’t have claws and they’re usually symmetrical. They can drive tent stakes, strike chisels, or even strike flooring nailers, if needed. They can also be handy for setting stepping stones and other landscaping items.

Rubber mallets don’t last forever, though. The rubber dry rots and deteriorates over time. But they’re usually inexpensive and readily available, so replacing them is rarely an issue.

Best For: Landscaping, tent stakes, chiseling

Our Recommendation: Stanley Rubber Mallet — Get it at Amazon for $13.12

Stanley’s rubber mallet is affordable and features a tough rubber head molded to a wooden handle for durability.

9. Sledge Hammer

A sledge hammer is the bigger, heavier cousin of the club hammer. These hammers have huge, heavy heads that can break rugged materials like stone and concrete. DIYers can also use them for knocking down drywall and the studs behind it, as well as for splitting wood with a wedge or many other purposes.

In general, sledge hammer heads weigh at least 6 pounds, and their handles are usually 36 inches long. This creates a lot of force when swung at an object, allowing the user to demolish heavy objects and remove them in smaller pieces. They can even move stud walls into place on a framing project, if needed.

Best For: Demolition, splitting wood, framing projects

Our Recommendation: Husky 10-pound Sledge Hammer — Get it at The Home Depot for $39.98

Husky’s 10-pound sledge hammer features a 36-inch long hickory handle to create plenty of force for demolition.

10. Tack Hammer

Tack hammers are used in some rather niche projects, such as upholstery or shoe repair. They’re lightweight hammers with long, pointy heads that allow the user to drive a tack with pin-point accuracy. They usually feature wooden handles, and the face opposite of the strike surface is claw shaped to remove tacks. Some models have magnetic heads that allow the user to start the tack with one hand.

These hammers are meant specifically for tacks, not nails. They can pin fabric in place, or drive small shoe tacks without bending them. DIYers can use them to reupholster chairs and other furniture items.

Best For: Upholstery projects and shoe repairs

Our Recommendation: Estwing Sure Strike Tack Hammer — Get it at Amazon for $19.86

Estwing’s Sure Strike Tack Hammer features a forged head, a hickory handle, and a built-in magnetic tack starter.

RELATED: How To: Use a Hammer

Specialty Hammers

While the above hammers are general purpose, the following are some of the more specific, specialty-type hammers that folks in certain trades often use. Many are used to drive special hardware or even work with specific materials.

11. Brick or Scutch Hammer

Brick or scutch hammers are used solely during masonry projects to modify bricks and blocks. They come in single scutch or double scutch versions. Single scutch hammers have a striking surface on one end and then a long, pointy neck with a slot in the end on the other. A scutch comb fits inside this slot, and it’s used to cut and shape bricks. Double scutch versions forgo the striking surface and instead feature two scutch slots.

To use these hammers, the mason or landscaper will strike the surface with the scutch comb to snap away material. They can do this to cut or shorten blocks, or simply to demolish stone or concrete where they need to run electrical lines or pipes.

Best For: Masonry projects

Our Recommendation: Draper Brick Scutch Hammer — Get it at Amazon for $36.90

The Draper Scutch hammer features a single-sided scutch design opposite a flat hammering face.

12. Bush or Axe Hammer

When concrete surfaces are too smooth, a mason or DIYer will give them a bit of texture with a bush hammer. These hammers have serrated teeth that bite down into the concrete surface, creating a bit of nonslip texture and grittiness to prevent slips.

Bush hammers are metal blocks on the end of a wooden handle. As mentioned, the faces of these hammers have serrated teeth that act as chisels to chip away small bits of concrete. The hardened steel used for bush hammer heads does make them fairly expensive, however, and most modern masons use power tools to texture concrete today.

Best For: Texturing concrete

Our Recommendation: Bon Bush Hammer — Get it at Amazon for $140.74

The pro-grade Bon Bush Hammer features 25 meticulously milled teeth and a 16-inch wooden handle for shock absorption.

13. Cross Peen Hammer

Cross peen hammers are metalworking and forging tools. They’re large and heavy, and resemble club hammers, however one side of the hammer has a tapered point that runs perpendicular to the handle. They generally have metal heads with wooden handles and weigh around 2 to 3 pounds.

These hammers are used to draw metal out, or make it larger and spread it once heated. They can even be used to cut heated metal, but not with much accuracy. They’re the most commonly used hammer types for blacksmithing for these reasons, and many DIYers may recognize them from these settings.

Best For: Metalworking and forging

Our Recommendation: Titan Cross Peen Hammer — Get it at Amazon for $25.36

This cross peen hammer from Titan features a heat-treated head for durability as well as a fiberglass handle to prevent fatigue and shock transmission.

14. Drywall Hammer

Drywall hammers are designed specifically for hanging drywall with nails. These hammers have big, round faces with cross-hatched patterns, and they create a perfect dimple in the drywall to make filling them with spackle easier. They also feature a hatchet side, as these tools were originally used by drywall installers to score sheets of drywall to size and cut out holes for outlets and other penetrations.

Drywall hammers are generally inexpensive because they don’t see a lot of force. The nails drive easily and drywall is not a difficult material to cut. Their heads are usually metal, but they often feature wooden handles to keep them lightweight and easy to carry.

Best For: Hanging drywall

Our Recommendation: Vaughan & Bushnell Drywall Hammer — Get it at Amazon for $44.92

Vaughan & Bushnell’s Drywall Hammer is lightweight enough for all-day drywalling projects, and the waffle-face is designed to grab a drywall nail nicely.

15. Brass Hammer

While brass hammers come in a wide range of sizes or styles, it’s less about what they look like and more about what they can do safely. The key feature is that brass doesn’t spark when it hits another metal object.

In conditions where explosive vapors or gasses could be present, these hammers are one of very few solutions. For example, most mechanics will use a brass hammer to tap the retaining ring off a fuel tank to remove the fuel pump.

These hammers can strike a punch without creating a spark. But, it’s also worth noting that to truly be safe, the punch should be brass as well.

Best For: Working around explosive gas or vapors

Our Recommendation: Real Steel Solid Brass Non-Sparking Hammer — Get it at Amazon for $20.80

Real Steel’s Solid Brass Hammer is an ideal do-all weight and the brass head won’t cause dangerous spark.

16. Hatchet Hammer

A hatchet hammer, also known as a rigger’s hatchet or rigster’s hatchet, is a large, heavy-duty hammer designed to drive framing nails. Typically, hatchet hammers have long handles like framing hammers, and similarly-shaped faces. However, opposite of the striking face is a large, thick, heavy-duty hatchet. These hammers can weigh 28 to 36 ounces, as well.

Originally, they were used to assemble scaffolding and rigging around large projects, and they could easily drive heavy-duty nails but also cut rope, lift objects, and do much more. Today, they’re much less commonly seen due to their heft and design, but they can be quite handy on a framing project.

Best For: Framing projects

Our Recommendation: Vaughan RB Rigster’s Hatchet — Get it at Amazon for $45.76

The Vaughan RB Rigster’s Hatchet features a built-in nail puller, a forged head, and a long, durable hickory handle.

17. Joiner’s Mallet

Joiner’s mallets might seem old school at first, but they’re very much a part of modern woodworking. These hammers are generally made from all wood (hardwood species like maple and ash, specifically), with a handle mated to the head through an eye, with many of these models using interesting pegs or joinery techniques to join the two. Occasionally, they may consist of a cylindrical synthetic material, but they’re a little less traditional.

Joiner’s mallets are typically used in woodworking projects when the user needs to strike high-end chisels. They provide a bit of shock absorption, minimize noise, and keep the chisel in good condition.

Best For: Joinery, woodworking, crafting

Our Recommendation: Bora Wooden Mallet — Get it at Amazon for $39.81

The Bora Wooden Mallet features a balanced design with a tapered 9-inch beechwood handle.

18. Linesman’s Hammer

Linesmen obviously have a difficult job. They work in all conditions and they’re frequently high overhead working with very high voltage. They have to be tough, and so do their hammers. Linesman hammers are generally large chunks of steel on the end of non-conductive fiberglass handle. They typically weigh more than 30 ounces and have 15- or 16-inch handles.

These hammers’ heads have serrated faces for driving heavy-duty lugs and hooks into power poles. Some have two faces, while others may have short, sturdy claws for removing staples and fasteners. These hammers often have eyelets in the handles for tethers, preventing the linesman from dropping them while working.

Best For: Heavy-duty electrical work

Our Recommendation: Klein Tools Lineman’s Straight Claw Hammer — Get it at Amazon for $66.29

The Klein Tools Lineman’s hammer has a heavy-duty design and a hickory handle to keep weight low without compromising strength.

19. Shingle or Roofing Hammer

Shingle or roofing hammers or hatchets are designed for installing strips (or individual) shingles, whether they be asphalt or wood. They’re heavy, weighing at least 20 ounces, and generally have square, serrated faces on one side and a curved hatchet face on the other. Attached to the face is usually a v-notched razor blade that the users can pull out or slide away, as well as a gauge used to adjust the height of the next course of shingles.

Most roofers these days use nail guns, so shingle hammers aren’t as popular as they used to be. And, the razor on the edge of the hatchet does take some getting used to. However, when it comes to wood shingles, these hatchets are still popular with installers as they can quickly split a shingle to width.

Best For: Installing asphalt or wooden shingles

Our Recommendation: Get the Estwing Shingler’s Hammer — Get it at Amazon for $32.97

Estwing’s Shingler’s Hammer features a built-in blade for cutting shingles, a spacing gauge, and a waffle face for grip on the nail.

RELATED: The Roofing Tools That Are Most Important for Repairs

20. Soft Face Hammer

Not everything that needs to be struck with a hammer is durable enough for metal. In cases where a hammer could dent, break, or mar a surface, a soft-faced hammer is a better choice. These models typically have metal heads attached to the end of a wooden or fiberglass handle, and they have replaceable pads on either side of the head. The user can strike the item with these pads and worry less about damaging it.

Soft faced hammers are popular in automotive situations, where mechanics shouldn’t hit plastic clips, delicate paint, and other small items or machined surfaces with a standard hammer. They can also be used to adjust wood framing, cabinetry, and other delicate woodworking pieces without denting or scratching the materials.

Best For: Automotive work and installations, cabinetry and woodworking applications

Our Recommendation: Stanley Soft Face Hammer — Get it at Amazon for $26.43

This soft face hammer from Stanley features swappable faces that won’t mar finished surfaces.

21. Straight Peen Hammer

Straight peen hammers are less popular than cross peen hammers, but they’re fairly similar in design. They feature sturdy metal heads attached to (typically) wooden handles, and they’re usually fairly heavy (2 to 4 pounds). They feature a flat striking surface and a tapered edge that runs parallel with the handle.

These hammers are useful with metalworking and blacksmithing projects. They can also draw out metal and spread it. They’re also used for stone cutting and shaping. With the peen inline with the handle, it’s easier to direct accurately than when using a cross peen.

Best For: Metalworking and blacksmithing, stone work

Our Recommendation: Bon RiverWorks Straight Peen Hammer — Get it at Amazon for $35.41

The Bon RiverWorks Straight Peen Driving Hammer features a hand forged steel head and crowned striking surfaces for accurate strikes.

22. Trim Hammer

Trim hammers are designed to work with smaller nails and delicate moldings. These hammers have smaller heads attached to shorter handles. Their faces are flat (or slightly rounded) and never feature serrated teeth. They can have both curved and straight claws, but straight claws are the most common. They generally weigh around 12 to 16 ounces.

These hammers are designed to drive light-duty finish nails, so they don’t need to be hefty or bulky. In fact, their size helps trim carpenters avoid striking the trim, flooring, molding, or carpentry they’re working on. When the nail gets close enough to the surface, the carpenter will typically switch to a hardened steel nail set to poke the nail below the surface, so these hammers have to be made from hardened steel to last.

Best For: Installing finish nails in molding, cabinetry, flooring, and other projects

Our Recommendation: Vaughan & Bushnell 16-ounce Finish Hammerer at Amazon for $37.99

This finish nailer features a compact head size that fits in tight places, as well as a hickory handle to help reduce fatigue.

23. Body Hammer

A body hammer is a type of striking tool used to shape metal panels. Most often, they’re used in body shops and custom metalworking shops to fix and shape fenders, gas tanks, and other metal projects. Some of the faces are rounded while others might be tapered, and they’re all used to force metal to react in a specific way, such as shrinking, spreading, or flattening.

These tools come in many shapes and sizes, but they generally consist of a metal head and a wooden handle. Some might feature fiberglass handles, which can be a benefit when it comes to shock absorption.

Best For: Shaping body panels and metalworking

Our Recommendation: Martin High Crown Cross Peen at Amazon for $56.63

The Martin High Crown Cross Peen Hammer has a slightly rounded face for forming radiuses, contours, and curves in metal projects.

24. Pneumatic Hammer

A pneumatic hammer is a striking tool that does not resemble a hammer at all. These tools are pistol shaped and require compressed air to operate. The user places a chisel or punch inside the pistol, holds it to the surface that they intend to strike, and then pulls to trigger to strike it rapidly and repeatedly.

Air hammers have a lot of uses. They can chisel rivets and welds apart, carve materials like stone and metal, and even set lugs into wheel hubs, in some cases. They’re a handy tool to have around, though they can be loud and tough to get used to at first.

Best For: Chipping, chiseling, cutting, and drilling metal or stone materials

Our Recommendation: Chicago Pneumatic Air Hammer — Get it at Amazon for $390.99

The Chicago Pneumatic Air Hammer provides up to 2,000 blows per minute and can handle a wide variety of chisels and punches.

25. Scaling Hammer

Scaling hammers are designed to remove scale and build-up from metal surfaces. They have two chisel-type surfaces on either end of the head, but they’re perpendicular. One resembles a cross peen while the other resembles a straight peen. This allows the user to chip away at scale from any angle without the user having to reposition their body.

Best For: Chipping scale and build-up off of metal surfaces

Our Recommendation: Faithfull Boilers’ Scaling Hammer at Amazon for $23.91

Faithfull Boiler’s Scaling Hammer features a lightweight design (just 16 ounces), two chisel-peens for chipping away at scale, and an affordable price point.

Hammer Safety Tips

Hammers are incredibly handy, but they can also be dangerous if used improperly. Learn how to get the most out of your hammer without hurting yourself.

- Always wear safety glasses when working with a hammer. Fasteners can go flying, and striking two hardened surfaces together can cause chunks of metal to dislodge.

- Before using a hammer, be sure to check the fit of the head. If the head is loose on the handle, rattling or sliding, the handle should be replaced before using.

- Attempt to strike every nail so that the face of the hammer lands flat on the nail head. This will prevent the nail from bending or shooting out from under the hammer head.

- When hammering a small nail, hold the nail in place with a pair of pliers or punch it through a small piece of cardboard to prevent hammering fingers.

- Getting a good grip means wrapping the thumb around the handle. Many folks try to place it along the handle for accuracy, but this can result in a hammer slipping.

- Use the right size hammer for the job. A small hammer may bend a large nail and send it flying, while a larger hammer may drive a small nail but damage the material in the process.

Prices listed here are accurate as of publication on April 27, 2023.