We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Precision cutting on a table saw, band saw, or router table can be demanding, and a good miter gauge makes it much easier. Simple miters on narrow boards can be cut with a hand saw and miter box, or with a powered miter saw. However, a miter saw can’t compete with a table saw when it comes to cutting wide boards and sheet material. But the table saw’s blade can’t be rotated to cut angles. The miter gauge solves this problem by guiding the workpiece into the blade at the proper angle. Unfortunately, the “free” miter gauges included with most shop tools leave much to be desired in terms of accuracy, adjustability, and repeatable results.

For this guide, we tested four popular aftermarket miter gauges, using our portable table saw. After three days of testing and more than 100 miter cuts, the JessEm Mite-R-Excel II became our all-around favorite. The compact telescoping fence and moderate-length miter bar were a good fit for our saw. The protractor, adjustment knobs, and sliding fence felt more sturdy than the others in the test group. The gauge was very accurate right out of the box, and the flip-stop mechanism was compatible with a sacrificial fence setup (which was not the case for every model we tested).

But our top pick will not be right for every user. Others we tested range from a capable budget model for basic joinery to high-precision devices better suited for larger freestanding saws. Read on to learn more about our selection criteria for the best miter gauges, our workshop test observations, and other highly rated options that we did not get to test.

- BEST OVERALL: JessEm Mite-R-Excel II

↓ Jump to Review - BEST BANG FOR THE BUCK: Fulton Precision Miter Gauge With Fence and Flip Stop

↓ Jump to Review - BEST FOR LARGE TABLES: Kreg KMS7102 Precision Miter Gauge System

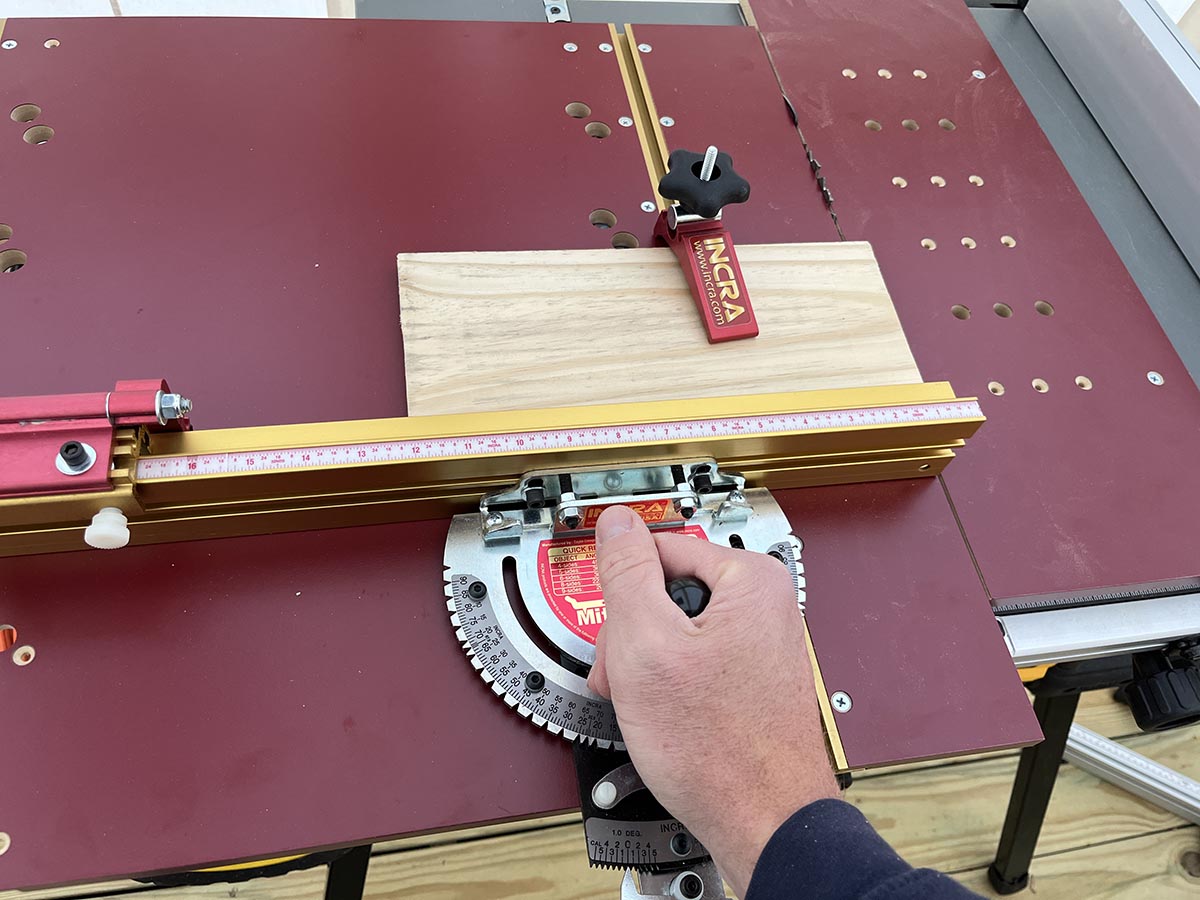

↓ Jump to Review - BEST WITH SLED: Incra Miter5000

↓ Jump to Review - BEST FOR BENCH TOOLS: Incra V27 Miter Gauge

↓ Jump to Review - BEST FOR BEGINNERS: Powertec Universal Table Saw Miter Gauge

↓ Jump to Review - BEST FOR EXPERTS: Incra 1000HD Miter Gauge

↓ Jump to Review - ALSO CONSIDER: The Original (Left Side) Dubby Cutoff Sled 3160

↓ Jump to Review

Our Top Picks

We chose the following miter gauges for testing based on their popularity among woodworkers. Each one offers its own blend of strengths for different projects, shop setups, and work styles.

Best Overall

JessEm Mite-R-Excel II

What We Like

- Sturdy aluminum construction

- Telescoping fence for full-length support

- 9 preset angles with spring-loaded indexing pins

- Adjustable-depth flip stop with micro adjuster

What We Don’t Like

- Short miter bar

- Assembly took longer than necessary

- More expensive than many other options

Specs

- Material: Steel and aluminum

- Fence: Adjustable 20 to 36 inches

- Quick stops: 9

Our Ratings: Ease of Use 5/5; Accuracy 5/5; Build Quality 5/5; Value 4.7/5

The JessEm Mite-R-Excel II has the precision necessary for fine woodworking combined with fast setting angles at 0, 10, 22.5, 30, and 45 degrees. At its shortest, the telescopic fence is suitable for small table saws, band saws, or router tables, yet it will extend out to 36 inches providing excellent workpiece support on large table saws. It also has flip and end stops for improved productivity when sawing high volumes.

Assembling this miter gauge took about 15 minutes, but should have only taken about five. The illustrations of the parts varied from the actual hardware, and one of the bolts was threaded differently than two others that otherwise looked identical at a glance. Once we figured it out, everything fit together perfectly.

The JessEm Mite-R-Excel II was just the right size to work with our portable table saw. The miter bar was the shortest among our test group, but we had no problem cutting 45-degree angles on boards up to 8 inches wide. And it was consistently accurate. We made the rounds cutting angles at all of the positive-stop positions, and after the fourth round, all of the pieces from each cutting position measured within 0.3 degrees or less.

What our tester says: “Just picking up the JessEm Mite-R-Excel II leaves the impression of quality. It is weighty—and dead-on accurate right out of the box. After adjusting the miter bar for a snug fit in our saw’s T-track, all of our matched cuts measured within 0.3 degrees of each other.” —Mark Wolfe, writer and product tester

Get the JessEm miter gauge at Amazon, Woodcraft, Lee Valley, Infinity Cutting Tools, or Walmart.

Best Bang for the Buck

Fulton Precision Miter Gauge With Fence and Flip Stop

What We Like

- Budget-friendly miter gauge

- Good accuracy for the price

- Beveled fence for improved support

- Works with T-track or straight slot tables

What We Don’t Like

- Measuring tap does not come pre-installed

Specs

- Material: Steel and aluminum

- Fence: 18.9 inches

- Quick stops: 13

Our Ratings: Ease of Use 4.3/5; Accuracy 5/5; Build Quality 5/5; Value 5/5

The Fulton miter gauge is a well-thought-out device, offering many features of much more expensive models. The sturdy aluminum head has settings for angles of 22.5, 30, 45, 60, 67.5, and 90 degrees and is capable of both left and right angles. A spring-loaded pin allows for rapid positioning. The main gauge is marked in single-degree increments.

The miter bar is 18.9 inches long, designed to eliminate play on the saw table slot. It will fit most straight and T-slot tables (though not Craftsman or Sears brands). The extruded aluminum fence has ends precut at 45 degrees, which allows workpiece support closer to the saw blade when cutting angles. A flip stop makes it easy to produce repetitive cuts.

In terms of basic functionality, the Fulton Precision miter gauge proved to be a very nice upgrade over the one that came with our table saw. The miter bar fit perfectly in the T-track slot on the table saw, and a few turns of the roller ball plungers achieved perfect alignment with no play. The 13 positive stops were perfectly accurate, quick, and easy to engage by means of a spring-loaded drop pin. Finding angles between the positive stops was a little trickier for repeat cuts. But all of our matched-angle cuts measured within 0.3 degrees. And the price was considerably lower than the other products we tested.

Get the Fulton miter gauge at Amazon or Wood Art Supply.

Best for Large Tables

Kreg KMS7102 Precision Miter Gauge System

What We Like

- 24-inch fence supports larger workpieces

- 0.1-degree angle resolution

- Large swing stop

- Mid-range price point

What We Don’t Like

- Felt oversized on our saw table

- Brass stop lock pin could be easily lost

Specs

- Material: Aluminum

- Fence: 24 inches

- Quick stops: 9

Our Ratings: Ease of Use 4.3/5; Accuracy 5/5; Build Quality 5/5; Value 5/5

The Kreg KMS7102 Miter Gauge was a bit larger than we preferred for working on our portable table saw, but would be a handy accessory for a large freestanding saw. This model’s protractor gauge is computer numerical control (CNC) machined, rather than pressed, and factory calibrated to within 0.003 inches. Positive stops at 0, 10, 22.5, 30, and 45 degrees to left and right allow for rapid setting of commonly used angles. Extra precision comes from a vernier scale that gives adjustment to 0.1 degrees and a micro adjuster capable of 0.01 degrees.

The table saw miter bar has five screw adjusters to ensure a snug fit in the table slot. The fence is 24 inches long—excellent for guiding long boards or large sheet material—and made of cast aluminum for rigidity. It has slots for mounting the Swing Stop workpiece positioning system, which also helps to improve the accuracy of repeat miter cuts.

The extra long miter bar allowed us to guide wider workpieces easily, but the long fence reminded us that our small portable table saw was not equipped to get the full value of the gauge. The KMS7102 would be great for cutting sheet material, but we would have needed a larger surface to support bigger workpieces. With its combination of competitive price and high performance, this miter gauge from Kreg is an excellent choice for freestanding table saws.

Get the Kreg miter gauge at Amazon, The Home Depot, Kreg, Menards, Grizzly, ToolNut, or Walmart.

Best with Sled

Incra Miter5000

What We Like

- Telescoping fence supports long workpieces

- Suitable for left or right side of the saw blade

- 364 positive stops in .5-degree increments

- Includes track clamp and swing stop

What We Don’t Like

- Premium price for an MDF sled

- Once assembled, cannot switch sides easily

Specs

- Material: Aluminum

- Fence: Adjustable 36 to 64 inches

- Quick stops: 364

Our Ratings: Ease of Use 4.3/5; Accuracy 5/5; Build Quality 5/5; Value 4.7/5

A sled offers the best workpiece support for miter cuts in wide panels because it carries the piece through the cut instead of pushing the piece into the blade. The Incra Miter 5000 miter sled features a laser cut steel protractor head with 364 angle stops, 36- to 64-inch telescoping fence. It also comes with such table saw miter gauge accessories as swing stop, and T-track clamp. The MDF sled base panels are easy to install for a zero-clearance cutting system, and customizable for cutting from the right or left side of the saw blade.

The Miter 5000 worked well on our portable table saw without added support, but that may not be the case for every saw and would not have been the case if we had to cut pieces longer than about 36 inches. The hardware was clearly labeled and the instructions were easy to follow, which made assembly a breeze. We installed the sled left of the blade, with the non-moving receiving panel mounted in the right-side miter track, following the instructions as written. There were also supplemental instructions for installing the sled on the right.

Setting the angles at 5-degree increments was a straightforward process, but setting between pre-marked angles required a 2-step process that took a little more time than other products we tested. That said, this system delivered incredibly accurate and repeatable results, with less than .1-degree difference between matched pieces. We especially liked the included T-track clamp for total support and control, particularly with small pieces.

What our tester says: “The Incra Miter 5000 was easy to set up, perfectly accurate, and worked well with the contractor table saw we used for testing. It was expensive, but way easier to use than just a miter gauge.” —Mark Wolfe, writer and product tester

Get the Incra Miter 5000 miter gauge at Amazon, Acme Tools, Woodcraft, Rockler, Grizzly, or Incra Tools.

More Great Options

If the models we tested don’t fit your needs, other great options remain. These highly rated miter gauges offer unique feature combinations for highly accurate cuts and easy adjustments.

Best for Bench Tools

Incra V27 Miter Gauge

What We Like

- 27 stops for most common angles

- Works with most benchtop saws and router tables

- Miter bar adjusts to fit most table tracks

- Affordable model from a premium brand

What We Don’t Like

- Fence is not included

- Periodic recalibration may be necessary

Specs

- Material: Steel

- Fence: Mounting bracket

- Quick stops: 27

Precision generally comes with a premium price tag. Still, this Incra model is not only affordable but also maximizes its value by tripling as a router table miter gauge, a sanding table miter gauge, or a band saw miter gauge. Where most miter heads have a handful of preset angle stops, the V27 takes its name from the 27 locking indents that make the setting of even unusual angles quick and easy.

The miter bar has an optional T-slot washer and adjustment that allows it to be used with many different woodworking machines. The only thing lacking is a fence. However, there are two slots machined into the head for attachment of shop-made alternatives. It’s constructed of highly durable chromed steel, so it’s sure to last a long time.

Get the Incra V27 miter gauge at Amazon, Walmart, Acme Tools, Woodcraft, or Incra Tools.

Best for Beginners

Powertec Universal Table Saw Miter Gauge

What We Like

- Proven design at a competitive price

- Compatible with slotted and non-slotted tables

- Guide plate accepts a variety of aftermarket accessories

What We Don’t Like

- Aluminum locating stops may wear over time

- Adding a fence will increase overall cost

Specs

- Material: Laser-cut aluminum

- Fence: Basic slotted

- Quick stops: 27

Many woodworkers never need to saw material to 0.1 of a degree. For beginners, a robust, low-cost miter gauge like this one from Powertec can be easier to use and more useful than something with extreme precision. But that doesn’t mean it’s short on features.

The head is thick laser-cut aluminum, offering the necessary accuracy and durability. There are 27 indents around the edge, with a pivoting locating mechanism that’s fast and easy to use. The miter bar has an adjustment, so it fits tightly in saw tables and can also be used with other machinery. While a miter gauge fence isn’t provided, there are fixing slots available for aftermarket or homemade additions. It is a basic miter gauge, which for some users might be the ideal solution.

Get the Powertec universal miter gauge at Amazon, The Home Depot, Powertec, or Walmart.

Best for Experts

Incra 1000HD Miter Gauge

What We Like

- Precisely machined and laser-cut components

- Fast-setting angle lock system in single-degree steps

- Telescopic fence provides excellent workpiece support

What We Don’t Like

- Premium price tag

Specs

- Material: Steel and aluminum

- Fence: 18 to 31 inches

- Quick stops: 180

This Incra miter gauge has been designed to satisfy the most demanding woodworker, offering both fine detail and great flexibility. The heavy-duty aluminum steel head of the 1000HD is laser cut and machined for high accuracy. It has fast, positive locking increments at every single degree and further fine adjustment to 0.1 degrees. The patented miter bar allows an almost perfect fit in saw table slots. There’s also a removable T-slot adapter.

The aluminum fence extends from 18 to 31 inches, offering excellent workpiece support while being compact enough for smaller saws. The accompanying adjustable flip stop provides accurate control over cut length. The Incra 1000HD miter gauge is a considerable investment, but for those who need a high level of accuracy time after time, it may be worth the expense.

Get the Incra 1000HD miter gauge at Amazon or Acme Tools.

Also Consider

The Original (Left Side) Dubby Cutoff Sled 3160

What We Like

- Cuts panels up to 24 inches wide by 52 inches long

- Hold-down clamp safely secures small pieces

- Pre-scribed miter cut lines for 4- to 16-sided frame angles

- Compatible with most cabinet and contractor table saws

- Choose from left side, right side, or both sides

What We Don’t Like

- Base may warp in a humid environment

- Does not include a zero-clearance tabletop

Specs

- Material: luminum and laminated medium-density fiberboard (MDF)

- Fence: 24 inches

- Quick stops: 1

Crosscut sleds are popular table saw accessories because they provide more support for larger panels than a fence alone. This typically increases accuracy and productivity. They also help to improve safety by keeping the hands further from the blade when cutting smaller pieces. The Dubby Original Cutoff Sled has garnered praise since the 1980s because it is simple to use and extremely accurate.

The Dubby features a laminated fiberboard base with scribed stainless steel angle gauge, and an extruded aluminum fence on a pivot. Simply move the outer end of the fence to the desired angle index line and tighten the knob for perfect cutting accuracy. The kit also includes a sliding stop with fine adjustment for repeat cuts, and a toggle hold-down clamp to secure the workpiece against the base. This system ensures an accurate cut every time while adding a measure of safety when working with smaller pieces.

Get the Dubby crosscut sled miter gauge at Amazon or Peachtree Woodworking Supply.

Jump to Our Top Picks

How We Chose and Tested the Best Miter Gauges

To identify our top picks, we started with a list of popular brands of aftermarket miter gauges. Then we listed features that enhance accuracy and repeatability, reduce setup and adjustment time, and increase durability and user safety. The models we tested earned high ratings from the experienced and beginner woodworkers who rely on them. To test each miter gauge, we used them to cut square ends and matched angles to form a square (8 45-degree angles) and an equilateral triangle (6 30-degree angles). Instead of cutting all of the matching angles in succession, we adjusted between cuts with alternate angles to test repeatability. After cutting all the pieces, we evaluated accuracy first by assembling the shapes, then by measuring each angled piece with a digital angle finder. Finally, we scored each tested model on a rubric and noted any other observations before assigning awards.

| Testing Stats | |

|---|---|

| Products tested | 4 |

| Time spent testing | 3 days |

| Tests performed | 6 |

| Price range | $80 to $400 |

What to Consider When Choosing a Miter Gauge

When a miter saw won’t cut it, a table saw miter gauge may help. The woodworker looking for a good miter gauge may be spoiled for choice, but as with any tool, some features should be prioritized over others. The following will help pinpoint the key benefits and highlight the versatility and potential creativity that the best miter gauge for table saw use can offer.

Construction

There are three main parts to a miter gauge: the miter bar, miter head, and fence.

Saw tables have a slot to accept various accessories. The miter bar is designed to fit in this, allowing the miter gauge to slide smoothly back and forth. The miter bar is often rectangular, though it may have an additional part shaped to fit table saws that have a T-slot in the table. The fit needs to be tight enough to maintain accuracy but not so tight that it jams in the slot. The best miter gauges can be adjusted to provide the right fit.

The miter head is semicircular and marked out for various angles. Increments vary from single degrees to .01 depending on the gauge. There’s usually a push handle, which is often also used to clamp the head at the correct angle, though a separate device may be employed.

The fence is fixed across the head and the workpiece rests against it. Fences may be solid or extendable. Longer fences provide better workpiece support but may not be suitable for small saws.

Material

Most miter gauges are made with components that are either steel or aluminum. Steel brings strength and durability, which is important for areas subject to frequent wear, like screw threads. However, steel is quite heavy and prone to rust. Aluminum is much lighter, highly resistant to corrosion, and is usually used for fences. These are normally sectional moldings that provide additional support and enough strength to avoid bending.

Nylon inserts or screws are frequently used to adjust how the miter bar (or miter gauge bar) fits in the slot on the saw table. These will wear out eventually and need to be replaced. Fortunately, they are not expensive.

Brass is sometimes used for handles and clamps. It’s very decorative but has no real influence on function.

Stops and Adjustments

To allow for setting of the cutting angle, the miter head rotates around a central point. As mentioned above, this is often clamped in the desired position using the push handle.

The head rotates through a total of 180 degrees, enabling the desired angle to be set with great freedom. However, certain angles—90 degrees, 45 degrees, and 22.5 degrees, for example—are used most often, so preset stops in the form of pins, holes, or grooves are often added. This makes setting the miter gauge much quicker.

More advanced miter gauges may provide stops in single-degree increments, though they normally still have a method of setting those common angles quickly.

Capacity

When shopping for a miter gauge, it’s important to consider the size of the saw table and the dimensions of the material that will be cut most often.

Budget miter gauges generally have a short fence of a fixed length. For those who have a compact miter and table saw and work with material of modest sizes, that’s not a problem. However, as material length increases, there’s a tendency for it to flex. If that happens, it can reduce cutting accuracy. Some of the best miter gauges have either longer or adjustable fences to combat this. The ability to set the fence to different lengths maximizes workpiece control. That said, it’s important to check their minimum length. Some models may actually be too long for smaller table saws.

Accuracy

Manufacturing quality has an impact on overall accuracy. On a low-cost table saw miter guide, the head might be punched out of a steel sheet, whereas on better models, this part is laser cut or machined from a solid block.

A basic, low-cost miter gauge will allow for the cutting of angles to within a degree or so. For those making rustic furniture or a gate for the yard, that could well be close enough. However, much greater accuracy is possible. Machined stops at single-degree increments are common and several can further refine this to 0.1-degree stops. Those who demand absolute precision may prefer a table saw gauge with a micro adjuster that can be set to 0.01 degrees.

While not a feature of budget models, the fence may also have a measuring scale for accurate alignment of the workpiece with the saw blade. Flip stops that attach to the fence and slide along preformed groves are sometimes provided. These help hold the workpiece in exactly the right place when cutting to length.

Ease of Use

One may assume a basic saw table miter gauge is the easiest to use. To some extent, that’s true. However, on a slightly more expensive miter gauge, some stops make for faster setting, which may speed up the overall work process.

The consistent accuracy of a high-quality miter gauge can make repetitive tasks easier and help reduce errors. While adding precision at this stage of a job might be seen as making a tool more difficult to use, it will often save time at later stages.

What’s important is how well suited a particular miter gauge is to the work that is being done. It could be argued that ease of use isn’t just about simplicity; it’s also about how easy it makes the whole job.

Tips on Using a Miter Gauge

When the new miter gauge arrives, buyers will likely be keen to use it as soon as possible. Before doing so, take a few minutes to check and make certain nothing is missing or was damaged in transit. The following quick tips will help maximize performance.

- Whether it’s a first miter gauge for those just learning the basics or an upgrade with more advanced features, always read the instructions. It can save a lot of time and frustration later. Before starting on a job that matters, test the miter gauge on a few offcuts or extra pieces of wood.

- There’s an old adage in woodworking: Measure twice and cut once. In this case, users should not only double-check their measurements but also check that the clamps are nice and tight. It can be frustrating if the gauge moves during a cut, plus it can be dangerous.

- Inaccurate cuts may not be due to the miter gauge; it could be the saw blade is out of alignment or not square to the table. Always check these parts before starting—which is a habit woodworkers should get into whether using a miter gauge or not.

FAQs

In this comprehensive guide to choosing the best miter gauge, we provided insight into how these tools work and how to pick the right model for your table saw. Nevertheless, it’s natural to still have questions. We tackle some of the most common ones here.

The blade can usually be tilted up to 45 degrees to cut angles on the edges of a board, but this kind of cut is called a bevel, not a miter. You’ll need to add a miter gauge to cut the proper angle for a miter with the saw blade in the upright position.

The slots on most table saw beds are the same, so a universal miter gauge ought to fit. However, there can be rare exceptions. It’s worth a quick check of your saw’s specifications before you buy your woodworking gauge.

You could argue that the standard miter cut is by nature a 45-degree taper. It’s also possible to cut two-sided and four-sided tapers at 45 degrees and, with creative use of your miter gauge, at various other angles. However, these are all quite short. If you need long tapers, you may want to invest in a taper jig.

The most common angles that woodworkers cut with a miter gauge are 90-, 45-, 22.5-, and 30- degrees, angled either to the right or left.

The miter gauge and the fence are both designed to be used alone. Use the miter gauge for cross-cuts and angles. Use the fence for rip cuts. Sliding a board into the sawblade with the miter gauge while the fence is in place risks binding the board against the fence.

Meet the Tester

Mark Wolfe is a writer, product tester, and serial DIYer who lives in an older home. When he isn’t writing, he spends his time upgrading, repairing, and replacing anything and everything in his home, yard, and garden. He tests and writes reviews about hand and power tools, lawn care and home repair products, and outdoor living goods.

Additional research provided by Bob Beacham