We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Most saws are typically sold with a budget blade, regardless of the saw type. Even the best miter saw includes a basic woodcutting version—which is adequate for chopping through store-bought lumber, but the finished cut can be a bit rough. These budget saw blades aren’t equipped to accurately saw thicker materials like hardwood, plywood, laminates, etc.

But cutting these materials becomes a breeze with the right saw blade, and there are many to choose from. The challenge is knowing how to pick the right one. This article offers a clear guide on how to select the best miter saw blade for a variety of purposes.

- BEST OVERALL: Makita A-93681 10-Inch 80-Tooth Miter Saw Blade

- BEST BANG FOR THE BUCK: Neiko 10768A 12-Inch Carbide Saw Blade

- BEST FOR PLYWOOD: Freud 10-Inch Ultimate Plywood & Melamine Blade

- BEST FOR COMPOSITE/PLASTIC: Irwin 10-Inch Miter Saw Blade

- BEST FINISH: Diablo D12100X Ultimate Polished Finish Saw Blade

- BEST TWIN PACK: DeWalt 12-Inch Construction Miter Saw Blade

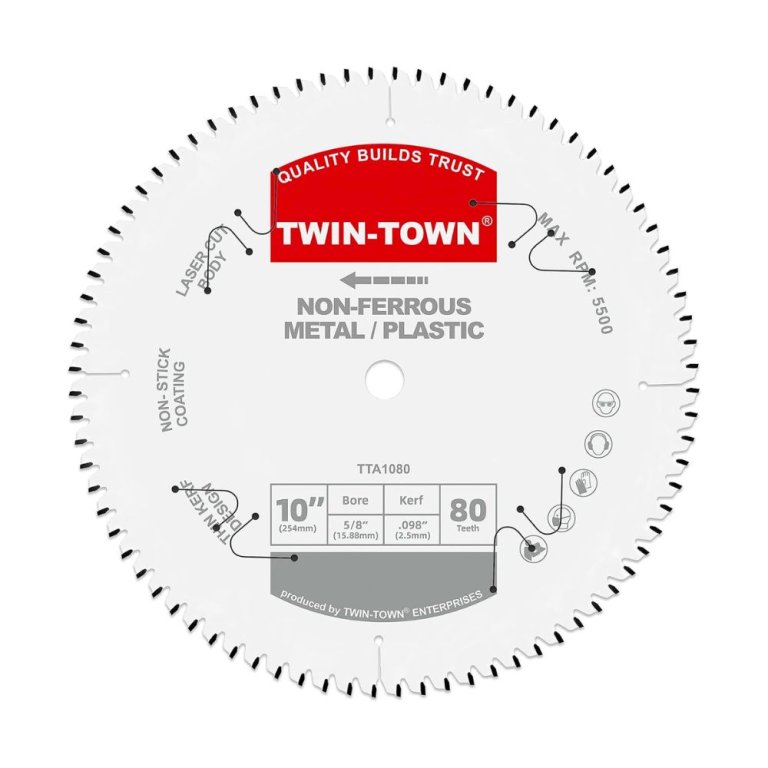

- BEST NONFERROUS METAL: Twin-Town 10-Inch Non-Ferrous Metal Saw Blade

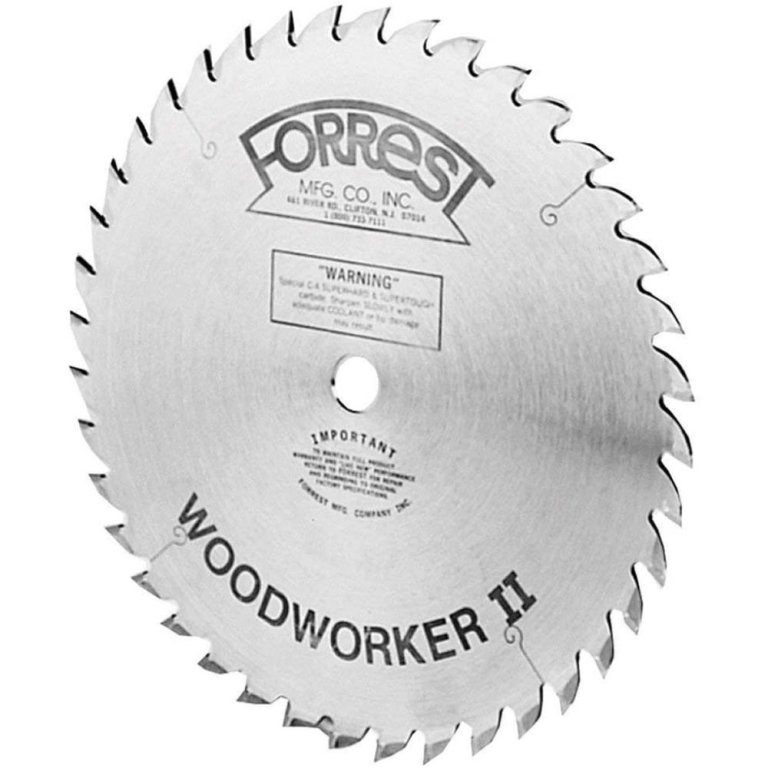

- ALSO CONSIDER: Forrest WW12487125A 12-Inch Woodworker II Saw Blade

How We Chose the Best Miter Saw Blades

Here at Bob Vila, we spend considerable time on research to ensure comprehensive coverage of a subject. My own background is in engineering, and after a change of career, I owned my own woodshop for 11 years. I have firsthand experience of using miter saws with many different blades.

In addition to diameter, blade material and tooth structure are key elements and thus the main focus when shopping for a new miter saw blade. Manufacturer reputation is important, too. Big brands consistently produce high-quality blades. Cheap miter saw blades are usually a poor investment, but value-for-money options are available, so I was careful not to overlook them.

Our Top Picks

It’s time to look at some real-world examples. The following blades come from top brands and have proven quality. Each product listed below includes a separate category so that you can quickly identify the best miter saw blade for a particular range of tasks.

Best Overall

Makita A-93681 10-Inch 80-Tooth Miter Saw Blade

Pros

- Teeth have Alternate Top Bevel (ATB) patterns with a 5-degree angle for clean cutting

- Hardened Japanese steel and carbide-tipped teeth provide long-term effectiveness

- Thin kerf on the 80 teeth provides accurate and precise cutting

Cons

- Limited material range compared to similar options on this list

Product Specs

- Blade diameter: 10 inches

- Tooth count: 80

- Materials: Hardwoods and softwoods

Choosing just one miter saw blade is something of a challenge, as many are quite function-specific. The Makita A-93681 takes the top spot because it offers excellent performance as a general-purpose blade for hardwoods and softwoods, but the finish exceeds that of many competitors. This reduces the need for further planing or sanding.

In part that’s due to the thin kerf of 0.091 inches, which allows great precision and minimal waste. It’s also a result of the carbide-tipped teeth, which have been honed to the equivalent of 600-grit abrasive. Teeth are ATB patterns with a 5-degree angle that helps clear waste from the cut line.

The competitive price should make it popular with both job site trades and DIY users.

Get the Makita miter saw blade at Amazon, The Home Depot, or Walmart.

Best Bang for the Buck

Neiko 10768A 12-Inch Carbide Saw Blade

Pros

- Ideal for DIY woodworking; compatible with standard miter saws

- Carbide-tipped teeth provide precise cuts and long-term durability

- Capable of withstanding high heat from frequent use

Cons

- Average finish quality may not last as long as some other blades

- Modest durability; may not be ideal for use on hardwoods

Product Specs

- Blade diameter: 12 inches

- Tooth count: 80

- Materials: Softwoods/dimensioned lumber

Many DIY users who buy a miter saw do so for cutting store-bought dimensioned lumber like 2x4s and planks for decking. This is invariably some kind of softwood. A fine finish to the cut isn’t required, which isn’t something the open-grain structure of softwood lends itself to anyway.

Neiko’s 12-inch carbide-tipped blade is ideal for this kind of cutting. The 80 teeth provide a perfectly acceptable finish and adequate precision. The blade is also designed to cope with the heat generated in high-productivity job site environments. This makes it a good choice for cutting framing for partition walls or other construction-related work. While it is capable of cutting hardwoods, it will wear much more quickly.

Get the Neiko miter saw blade at Amazon or Walmart.

Best for Plywood

Freud 10-Inch Ultimate Plywood & Melamine Blade

Pros

- Hi-ATB teeth reduce chipping and splinters for a smoother, precise cut

- Engineered for maximum stability with laser-cut anti-vibration slots

- Versatile construction is suitable for a wide variety of applications and materials

Cons

- Pricey compared to some other options on this list

Product Specs

- Blade diameter: 10 inches

- Tooth count: 80

- Materials: Plywood, melamine, laminates, hardwood, and fine moldings

Freud is a leading maker of miter saw blades, each of which is of exceptional quality. The company makes its own carbide that includes titanium and cobalt, which results in very sharp, hard-wearing teeth. Freud blades also have a proprietary Perma-Shield, a nonstick coating that reduces friction when cutting and makes the blades easy to clean.

This 10-inch plywood and melamine blade has Hi-ATB teeth designed to slice through laminated surfaces with minimal chipping or splintering. It also results in a very clean finish in hardwoods, making this a very versatile saw blade. Expansion slots are not unusual, but the Freud blade also has laser-cut, anti-vibration slots to maximize blade stability. These features help maintain a clean cut in materials with fragile surfaces.

Get the Freud miter saw blade at Amazon.

Best for Composite/Plastic

Irwin 10-Inch Miter Saw Blade

Pros

- Tough high-carbon steel construction provides maximum durability

- Great versatility in man-made materials like OSB and veneered boards

- Affordably priced for all of the features included; suitable for DIYers

Cons

- Tends to warp if overheated; may not be ideal for bustling workshops or jobsites

- Not designed for natural woods

Product Specs

- Blade diameter: 10 inches

- Tooth count: 180

- Materials: Oriented strand board (OSB), veneered products, plywood, plastics

This 10-inch high-carbon steel blade from Irwin is very basic in design but is effective nevertheless. While carbon steel is much harder than ordinary steel, it’s not of as good quality as carbide, but it does keep the cost down.

The thin 0.09-inch kerf, high tooth count, and aggressive angle are perfect for cutting through materials like OSB and veneered boards. This blade is also efficient at cutting the kind of plastics used for electrical conduits, vinyl fence posts, and similar materials. However, with no expansion slots, it may need occasional breaks to prevent overheating and blade warp.

The majority of DIY users may not need a blade like this very often, but the price is so low that it’s an affordable extra to keep handy for just-in-case occasions.

Get the Irwin miter saw blade at Amazon.

Best Finish

Diablo D12100X Ultimate Polished Finish Saw Blade

Pros

- Superb cut finish with a kerf of 0.098 inches and a friction-resistant Perma-Shield coating

- Advanced TiCo Hi-Density carbide, titanium, and cobalt construction

- Suitable for crosscuts and chip-free edges; perfect for crafters, DIYers, or furniture builders

Cons

- Slightly more expensive than comparable blades on the market

- Some users have reported jagged edges and some splintering

Product Specs

- Blade diameter: 12 inches

- Tooth count: 100

- Materials: Hardwood, softwood, melamine, and veneered plywood

High-quality woodworking demands precision cutting and finer finishes. This 100-tooth ultrafine blade from Diablo is designed to deliver both.

The Diablo D12100X blade has a fine kerf of just 0.098 inches. The teeth are made of Freud’s very own hard TiCo Hi-Density blend of carbide, titanium, and cobalt. The profile is also a Freud development called Axial Shear Face Grind (ASFG) that slices cleanly through wood fibers. It leaves a finish that is as smooth as surfaces that have been worked with 220-grit sandpaper.

As with most Freud miter saw blades, this Diablo one is coated with friction-reducing Perma-Shield. It helps shrug off the gunk and resin often found in composite boards and, in conjunction with expansion slots, reduces heat buildup. Plus, the Diablo D12100X is compatible with miter saws and slide miter saws.

Get the Diablo miter saw blade at The Home Depot or Northern Tool + Equipment.

Best Twin Pack

DeWalt 12-Inch Construction Miter Saw Blade

Pros

- Great versatility; comes with 2 blades of different tooth counts to suit a variety of projects

- Proven DeWalt durability with the help of the tungsten carbide tips

- Nonstick coating and expansion slots reduce heat and vibration

- Inexpensive blades compared to some other options available

Cons

- Not for melamine or other laminate materials

Product Specs

- Blade diameter: 12 inches

- Tooth count: 32 and 80

- Materials: Hardwood, softwood, plywood

DeWalt’s two-blade pack offers the perfect solution for most DIY users and many tradespeople, too. One blade has 32 teeth and is intended as a rapid-cutting, general-purpose blade for chopping through dimensioned lumber when cut finish isn’t particularly important. The other has 80 teeth and is designed to produce a clean finish on both hardwoods and softwoods.

Both blades have a fine kerf of 0.095 inches, which will provide good accuracy and minimal waste. Teeth are tungsten carbide tipped, with a 7-degree angle—a good compromise between speed and precision.

Expansion slots reduce heat and vibration, and there is also a nonstick coating. Given the competitive price, it’s no surprise that DeWalt’s two-blade pack is extremely popular and considered among the best 12-inch miter saw blade options.

Get the DeWalt miter saw blade at Amazon or The Home Depot.

Best Nonferrous Metal

Twin-Town 10-Inch Non-Ferrous Metal Saw Blade

Pros

- Allows for effective metal cutting with standard woodworking miter saws

- Durable construction with tungsten carbide teeth and a 5-degree angle

- Stabilizer vents integrated to prevent heat buildup and friction

Cons

- Not built for cutting harder materials like steel

Product Specs

- Blade diameter: 10 inches (12 inches available)

- Tooth count: 80

- Materials: Aluminum, brass, copper, plastic, PVC

Whether or not a miter saw can cut metal is a common question. With this blade from Twin-Town, the answer is “Yes!” (within certain parameters, of course). It’s great for cutting aluminum sections, copper pipes, small-diameter brass bars, etc. This blade can also tackle a wide variety of plastics. It isn’t intended for cutting through solid metals of considerable thickness. While no maximum is given, it’s likely to struggle over about ¼ inch.

The tungsten carbide teeth have a negative 5-degree angle that adds strength and makes for good durability. The stabilizer vents are particularly important in reducing heat buildup, which is more rapid when cutting metals. Overall, this blade is an affordable, versatile option for the DIY user and for site work.

Get the Twin-Town miter saw blade at Amazon.

Also Consider

Forrest WW12487125A 12-Inch Woodworker II Saw Blade

Pros

- Premium quality with carbide teeth that are 40 percent harder than typical models

- 15-degree tooth angle is made for quick and aggressive cutting

- Can be resharpened as necessary after use; suitable for the nonwasteful consumer

Cons

- Slightly thicker kerf than other available models; may chip or splinter

Product Specs

- Blade diameter: 12 inches

- Tooth count: 48

- Materials: Hardwood and softwood

Forrest focuses on producing miter saw blades for precision woodworking; the quality is outstanding. Carbide for the teeth comes from specialist supplier C4 and is claimed to be 40 percent harder than normal carbide, which may extend its working life up to three times.

The kerf is 0.125 inches, which is thin but not ultrathin. The tooth angle is 15 degrees, which provides fast, aggressive cutting on multiple types of wood. With only 48 teeth, a fairly coarse finish might be expected, but the opposite is true. The finish is so smooth that further planing or sanding is often unnecessary.

Forrest blades are expensive, but while almost all other miter saws blades are disposable, these can be resharpened. That said, it’s not a job for the amateur, so this blade is likely to appeal to the professional rather than the DIY user.

Get the Forrest miter saw blade at Amazon.

Jump to Our Top Picks

What to Consider When Choosing a Miter Saw Blade

While a good miter box is perfectly capable of cutting one or two joints, most people choose a powered miter saw for convenience and speed. These saws can be found in wood shops and at job sites, often mounted on a convenient stand.

One of the key reasons for their versatility is the variety of blades available, allowing users to maximize performance with different materials. In this section, we cover what differentiates one blade from another.

Type of Saw

There are several types of miter saws: Compound miter saws cut miters and bevels, sliding miter saws have horizontal rails that increase cutting width, and sliding compound miter saws combine both. Most bevel on one side, but some can bevel on both.

Each saw is named according to the diameter of its blade. Mini miter saws can be as small as 2 inches, while larger saws can be up to 15 inches. However, 10-inch and 12-inch blades are the most common.

Types of Miter Saw Blades

Miter saw blades are generally termed “crosscut” blades because they cut across the material, not along it.

Ripping blades, for cutting quickly along the grain, are a common choice for table saws but that’s not how a miter saw works. That said, some dual-purpose miter saw blades are described as crosscut and ripping.

A general-purpose miter saw blade is supplied with the machine when new. While general-purpose saw blades can be good all-arounders, they have their limits. With other types of blades, the description usually gives a good idea of the purpose. The name might also refer to the type of material to be cut: a plywood blade or a nonferrous metal blade. Other types of miter saw blades are suited to laminate and melamine. Blade material, thickness, and type of teeth all have a major impact when it comes to performance, which will be examined in detail in the following sections.

Material

The body of a miter saw blade is invariably made of steel. Japanese steel is known for its quality in blade production.

Steel rusts, so most miter saw blades are coated with a special substance to prevent corrosion. High-end coatings may also disperse heat and provide a nonstick surface, both of which make for easier cutting. Most blades are designed with slots cut into the body, which look like elongated question marks. These are known as expansion slots or stabilizer vents; they’re there so the blade doesn’t warp as it gets hot. Expansion slots may also reduce blade vibration, which can improve the finish.

Teeth are generally cut from the same piece of steel. Many have tungsten carbide tips that have been brazed (welded) on. These tips, often just called “carbide,” are harder than steel and stay sharp longer, thus improving blade life.

Size, Thickness, and Kerf

The size of the blade should match the miter saw. Putting a 10-inch blade on a 12-inch saw isn’t a good idea. It’ll spoil the dynamics, probably won’t run at the intended speed, and will reduce cutting capacity. It’s also important to check the arbor size (effectively the hole in the middle) as this is how it mounts onto the saw. Normally a 10-inch blade has a ⅝-inch arbor size and a 12-inch blade has a 1-inch arbor, though there are variations.

The thickness of the blade defines the size of kerf, or width of cut. A general-purpose miter saw blade is comparatively thick and has a wide kerf. This is fine when chopping through dimensioned softwood from the DIY store, but not for precision woodworking with expensive hardwoods—that requires a thinner kerf. These are also better for laminates because narrower teeth cause less surface chipping.

Number of Teeth, Tooth Shape, and Configuration

The number of teeth helps define the speed the saw will cut and the finish. Generally speaking, a blade with fewer teeth cuts faster. A blade with more teeth leaves a smoother finish. A 30- or 40-tooth blade is fine for chopping through 2×4 lumber quickly. A 100-tooth blade could leave a fine finish on dense hardwood.

The tooth shape and configuration also have a major impact. Many crosscut blades have a tooth shape called Alternate Top Bevel (ATB) where the cutting edge is on the right of the tooth, then the left, for each consecutive tooth. Plywood and laminate blades may be High Alternate Top Bevel (HATB or Hi-ATB), where in addition to alternate edges, the teeth also have a steep (high) cutting angle to minimize chipping.

Combination blades (for crosscutting and ripping blades) mix ATB teeth with Flat Top (FT) teeth, usually at a ratio of 4 ATB to 1 FT. Finally, Triple (or Triple Chip) teeth, which alternate a tall, slender tooth and a flat tooth are frequently found on blades for plastics and nonferrous metals.

Gullet and Hook Angle

The gullet is the area between teeth. It helps waste material to clear from the blade so the teeth don’t clog in the cut. This would both slow the blade and cause overheating. On combination blades, gullets are large to allow for fast ripping through softwoods, which tend to produce a lot of sawdust. On crosscut miter saw blades, the gullets are smaller because the material is broken down into smaller pieces and blade binding is less likely. They can also provide a degree of resistance during cutting so users don’t force the blade through too quickly and spoil what would otherwise be a clean finish.

Hook angle also affects feed rate. On a ripping or combination blade, there will be an aggressive forward lean (an angle of around 20 degrees) that promotes fast cutting. Crosscut miter saw blades tend to have shallow or even negative angles for slower, more precise cutting and, again, to allow for blade cooling.

FAQs

The sections above contain a wealth of technical and practical information to help you decide on the best miter saw blade (or blades) for your needs. However, during our research, we found a number of questions from potential buyers that crop up quite often. You can find the answers to the most common ones below.

Q.How do I clean and maintain a miter saw blade?

Remove the blade and place it in a bowl or tray. Use a diluted all-purpose household cleaner and a cleaning pad (not a scourer). Use a toothbrush around the teeth. Work slowly so you don’t slip and cut yourself. Avoid oven cleaners; they can damage carbide tips.

Q.How many teeth should a miter saw blade have?

It depends on what you want to use it for, which is why it’s common to have several different saw blades. The article above answers this question in more detail.

Q. Can I use a 10-inch blade on a 12-inch miter saw?

If the arbor is the same size, it can be done. However, we wouldn’t recommend it. A 10-inch saw blade is usually designed to rotate faster, so the slower motor of the 12-inch saw may not power it efficiently. Also, the smaller diameter blade will descend in a different position, reducing cutting capacity.

Q. Can I use my miter saw to cut metal?

You can, but there are limits. You will certainly need a metal-cutting blade. Nonferrous blades cut aluminum, brass, and copper. Steel-cutting blades are available, but they’re not really suited to the majority of miter saws. If you need to cut steel regularly, then a dedicated metal-cutting miter saw is recommended.

Q. What blade should I use to cut hardwood flooring?

We would suggest a blade with 80 or more teeth for a smooth finish. Our top pick or a plywood blade would suit the task.

Q. Are more teeth on a saw blade better?

Not necessarily. The number of teeth affects the speed of cutting and the quality of finish as discussed above.