We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Chop saws are best for making fast, straight cuts through tough materials like metal and masonry. Miter saws, on the other hand, are best suited to make angled and precise crosscuts in wood, and are the go-to saw for trim work, framing, and woodworking projects.

While these two power tools might look similar at first glance (comparable motors, blades, and fences), their functions and uses are quite different. Confusing them can lead to wasted time, money, and materials. In this guide, we’ll break down the key differences between chop saws and miter saws so you can choose the right tool for your next project.

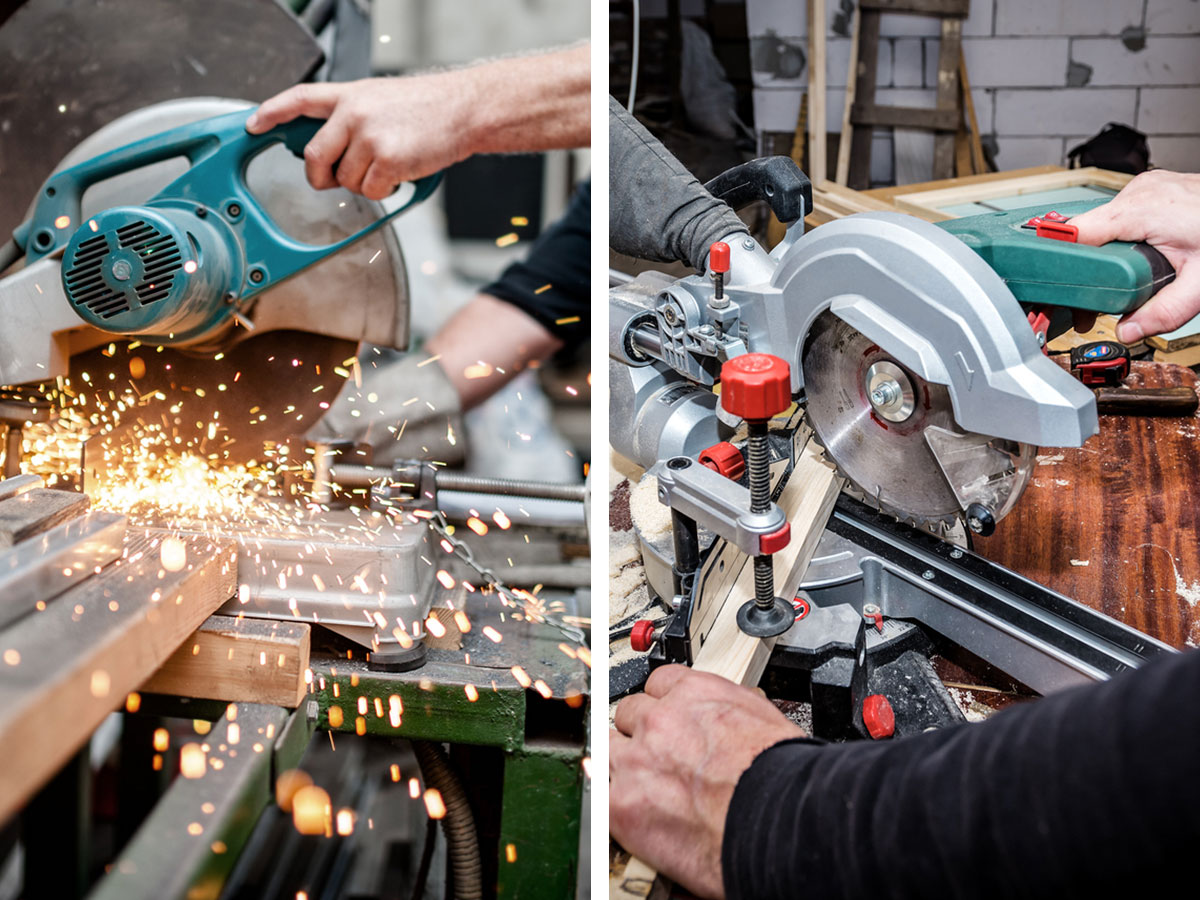

What is a chop saw?

A chop saw is a powerful, no-frills cutting tool designed primarily for making straight, 90-degree cuts through hard materials like metal, tile, and masonry. It’s built for speed and durability rather than finesse, so it is a staple on construction sites and in metalworking shops.

Best for:

- Cutting through tough materials like steel, rebar, aluminum, or concrete

- Projects where precise angles or detailed finish work aren’t required

Pros:

- Powerful motor handles dense materials with ease

- Makes fast, efficient straight cuts

- Typically more durable and lower maintenance

Cons:

- Can make only straight, 90-degree cuts

- Not suitable for detailed woodworking or trim

- Usually lacks safety and dust-collection features found in miter saws

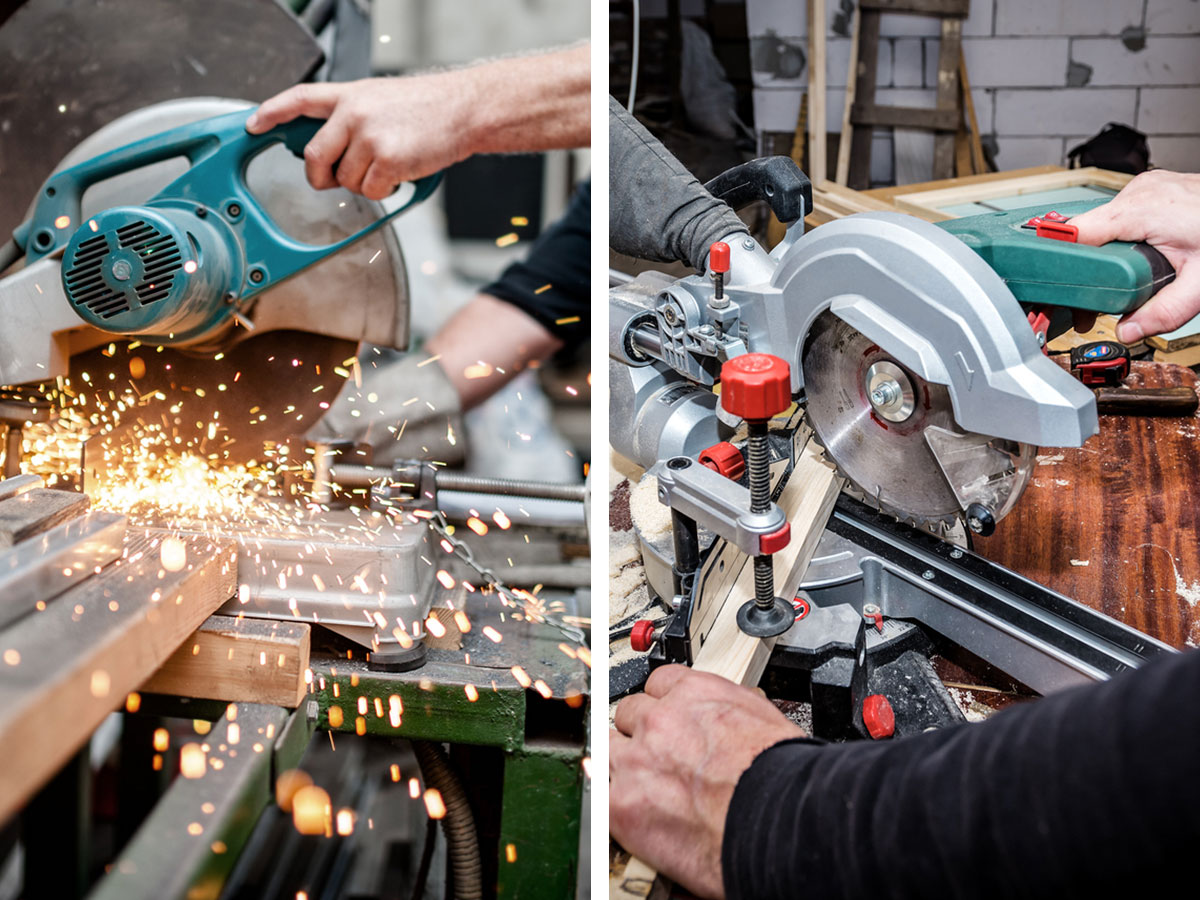

What is a miter saw?

A miter saw is a precision cutting tool used primarily in woodworking. It’s fantastic at making accurate angled cuts, so it’s ideal for projects like crown molding, picture frames, baseboards, and furniture building. Many models also tilt for bevel cuts, adding even more versatility.

Best for:

- Woodworking, finish carpentry, and DIY home projects

- Cutting angles and bevels with precision and control

Pros:

- Makes straight, miter, bevel, and compound cuts

- Highly accurate and great for detailed finish work

- Often includes safety features like blade guards and dust collection

Cons:

- Typically more expensive than basic chop saws

- Not designed to cut through metal or masonry

- Less durable when used on heavy-duty materials

Recommended Tools

DeWalt 12-Inch Sliding Compound Miter Saw on Amazon for $649.

DeWalt’s miter saws consistently top independent reviews, and this model offers class-leading capacities, repeatable precision, and outstanding reliability.

Porter-Cable Chop Saw on Amazon for $159.

A powerful 15-amp motor, 14-inch blade, and competitive pricing make this a great choice for home users or small engineering shops.

Differences Between Chop Saws and Miter Saws

DIYers might find the different types of saws available confusing when buying a saw or choosing the best one for a specific job. For example, miter saws and table saws also have similar features, but differ in key ways such as the length of the wood material.

Precision

Chop saws make straight, 90-degree cuts in a simple up-and-down motion. That’s where the “chop” comes from in the name. They’re designed strictly for crosscuts and can’t pivot for angled or bevel cuts. Some models might have adjustable fences, but the blade itself stays fixed.

This is a key difference between a chop saw and a miter saw, as their limited range of motion makes chop saws ideal for high-volume, straight-cut tasks, especially in metalworking or masonry environments where speed and power matter more than precision.

Unlike chop saws, miter saws can rotate to make angled (miter) cuts and tilt for bevel cuts. Many models include preset detents for common angles, speeding up setup and ensuring accuracy.

- Compound miter saws add even more flexibility by tilting the blade for compound cuts.

- Sliding models extend the cutting range by allowing the blade to move forward and backward—making them ideal for wider boards and more complex woodworking projects.

Materials They Cut

Chop saws are built for cutting metal and other dense materials. Most use abrasive cutting wheels instead of toothed blades, which are ideal for steel, cast iron, and other hard metals. Some can be fitted with toothed blades for softer metals like aluminum and brass, but these are not designed for fine or detailed work.

Miter saws, by contrast, are designed primarily for cutting wood. They’re great at making precise cuts in framing lumber, trim, and hardwoods. With the right miter saw blade, they also can handle materials like plywood, melamine, or even small pieces of nonferrous metal.

Note: Metal-cutting is not a miter saw’s specialty and can damage the tool over time.

Blade compatibility and RPM differences mean the blades on these two saw types are not interchangeable, even if they look like they’re the same size.

Weight and Operating Speed

While a metal chop or circular saw is usually a benchtop device, it is often a large and heavy tool. Manufacturers recommend bolting chop saws down to provide adequate stability and safety. Most have a blade size that ranges from 12 to 15 inches.

Chop saws generally run much more slowly than miter saws, typically around 1,500 revolutions per minute (RPS) rather than 3,000-plus RPM for miter saws. Using this saw to cut metal too quickly can cause excess heat, and as the metal expands, there’s a danger it will bind the blade.

An interesting development in the past few years for those considering a miter saw vs a chop saw has been the hybrid chop saw, like this multipurpose saw from Evolution Power Tools. These are a more compact model with 7¼-inch blades designed for DIY use. While still intended mostly as a metal-cutting tool, hybrid saws also can cut wood, and they are particularly useful if converting old pallets or scrap wood that might have nails or staples hidden inside.

Versatility

A miter saw is not just a very versatile wood cutting saw; it also comes in a wide variety of sizes. Like chop saws, they are described by their blade size.

- 8½-inch models are very compact and lightweight, yet they can still offer good cutting capacities.

- 10-inch miter saws are probably the most popular DIY tool.

Since they are lighter than most chop saws, miter saws are more portable and hence more versatile and popular on the job site. They often can rest on any available surface (or even the floor), but a variety of leg stands and workstations can hold them in place. These fold down for easy transportation but provide a comfortable working height and a stable sawing platform.

Choosing the Right Saw for Your Project

In the chop saw vs. miter saw debate, the tools look similar, but they don’t quite do the same thing. A chop saw is great for tough, repetitive cuts in industrial materials. A miter saw is a precision instrument for detail and finish work.

When choosing between them, think about the materials you’ll be cutting most often, and whether speed or accuracy is your top priority. The right tool will make a huge difference in the quality and ease of your work.