We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Air compressors are more than just helpful tools for mechanics or builders. While they’re certainly a key part of many professional tool kits, the right model can tackle a whole host of jobs around the house and yard including inflating a kiddie pool, painting walls with a paint sprayer, and cleaning and detailing a vehicle. The best home air compressors can provide years of trouble-free service.

Unfortunately, air compressors are often heavy and loud, so they are sometimes seen as difficult to work with or dangerous. Neither is true. So in this article we’re going to take a detailed look at how to use an air compressor, how to maintain it, and how to stay safe.

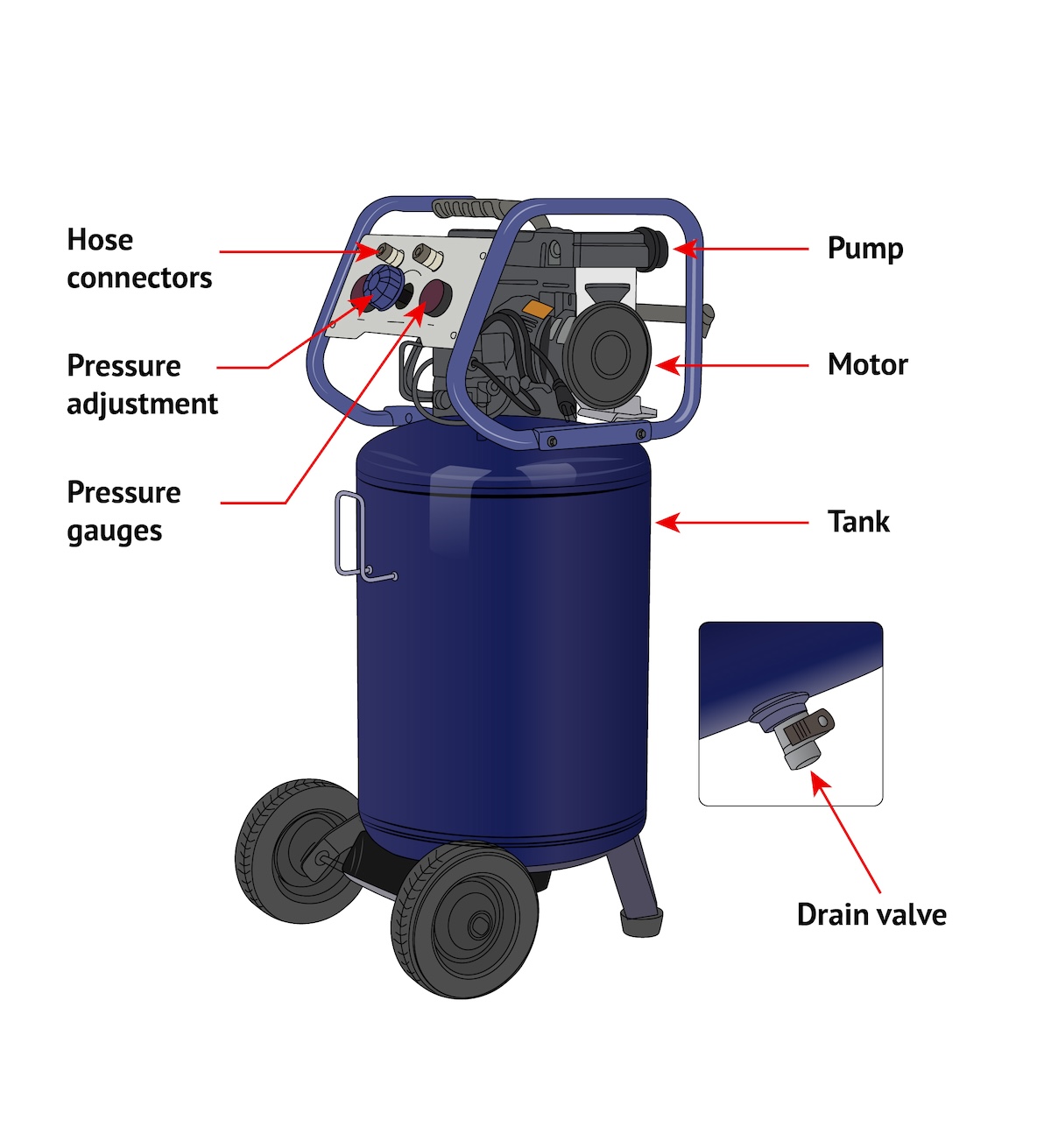

Important Air Compressor Parts

If you want to know how to use an air compressor, it helps to have an understanding of the tool’s key parts and the role each plays in its performance.

- Motor: Although gas and diesel motors are found on large commercial air compressors, electric motors that plug into a standard household outlet are also common.

- Pump: The motor drives the pump that compresses the air—either for immediate use or for storage.

- Tank (or receiver): Tire inflator air compressors do not have a tank so they need to run continuously. Other types store compressed air in one or more tanks. This allows the motor to rest, saving energy and prolonging its life. The motor will normally restart automatically when the air pressure drops.

- Pressure gauge(s): On tire inflators a single gauge shows the air pressure inside the tire. Other types of air compressor have two gauges. One shows the pressure in the tank, the other measures the regulator (output) pressure.

- Pressure adjustment: Basic air compressors may run at a fixed pressure but most have a dial or knob to adjust the output.

- Hose connector(s): Most tools have either one or two of these air compressor fittings. The hose connector is where you plug in the air compressor hoses that connect to your tools.

- Drain valve: Air contains water that is squeezed out when it is compressed. This water and lubricating oil get into the system, and need to be removed periodically so an air compressor drain valve is located at the bottom of the tank.

Air Compressor Safety Tips

Using an air compressor is not inherently dangerous but it’s worth taking a few simple precautions. The following air compressor tips will help prevent accidents.

- First and foremost, read the operating manual carefully and follow the manufacturer’s instructions.

- Always wear eye protection. Some kind of ear defenders are also a good idea.

- Air compressors that are permanently or semi-permanently sited in garages or workshops should be somewhere with plenty of air flow to prevent overheating.

- Although kids love to help, the air compressor and hoses can be a trip hazard so it’s best to keep them away from the work area.

- Never operate air compressor tools if you’re feeling tired or unwell. If you can’t stay focussed, you risk serious injury.

Tool Tip

Supported by Craftsman

A garage workshop essential, the Craftsman portable air compressor’s 125 PSI can power pneumatic tools such as a nail gun, impact wrench, or paint sprayer as easily as it inflates tires and sports equipment. Mount the compressor on a vertical surface to save space (trust us: you’ll want to keep it accessible!), then pull out the retractable 30-foot air hose as needed.

Get the Craftsman 0.5-Gallon Wall-Mountable & Portable Air Compressor at Lowe’s for $159

How to Use an Air Compressor with Power Tools

It’s common to use an air compressor with tools like nail guns, sanders, wrenches, etc. Their versatility is one of their main selling points.

STEP 1: Set up the air compressor.

Your air compressor setup will depend on how you intend to use your air compressor. No matter the location you choose, setting up an air compressor is easy:

- Unbox the tool and read the manual (did we mention that already?).

- Depending on the model, it may be necessary to attach wheels and air and oil filters.

- Some models require oil that needs to be added before first use. Many are oil-free.

- Plug the air compressor into a standard household outlet.

STEP 2: Fill the tank.

Turn the air compressor on. Some have a rocker switch, and others have a start button. The tank will now begin to fill with compressed air. Any tool attached at this point may not function correctly because there is insufficient air pressure. However, even on high capacity models, filling the tank only takes a few minutes. When the tank is full, the motor will stop. The air pressure inside the tank is displayed on the tank pressure gauge.

STEP 3: Set the pressure regulator.

Each pneumatic tool has air pressure requirements. For example, 90 PSI (pounds per square inch) is normal for sanders, grinders, and impact wrenches but an HVLP spray gun might only need 25 to 30 PSI. If the air pressure supplied is too high it can damage the tool. Blown seals that allow air to escape are a common problem. Check the PSI demanded by the tool and adjust the regulator to suit.

STEP 4: Attach the hose and tool.

The type of air compressor we are discussing usually has convenient quick-release fittings. A 1/4-inch universal is the most common size on the compressor, but hoses can also be 3/8-inch or 1/2-inch. To complicate matters, ‘universal’ doesn’t necessarily accept all types of connector. Automotive and industrial types may not seal correctly allowing air to escape and reducing performance. In truth, these problems are rare but it’s a good idea to check that the air compressor, hose, and tool are compatible. Fortunately, adaptors are low cost items and are widely available.

Plug the air hose into the compressor. Attach the other end of the hose to the tool, and you’re good to go. Press the trigger on the tool in the same way as you would any cordless or corded device. As the air in the tank is used up, the motor will automatically restart to maintain pressure.

3 Other Ways to Use an Air Compressor Around the House

Air compressors are popular for use with DIY and workshop tools, but there are several other ways these devices can come in handy.

Duster/Blow Gun

Add a blow gun to your air compressor and you have a tool that can clear the dust off woodworking projects before finishing, remove debris from all kinds of mechanical components, and clean hard to reach places like refrigerator motor compartments. They are also popular for car detailing. Vacuums can struggle to remove dirt from clingy carpets and trim gaps. An air compressor can be used to blow it out instead.

Crafting & Hobbies

Portable air compressors are great for crafters and hobbyists. They can power lightweight staplers for upholstery or framing. They can drive a pneumatic glue gun and there are air-powered engravers. Although artists’ airbrushes might seem too delicate for a full-size air compressor, if the regulator can be turned down to around 20 PSI, they work fine. All you need is a hose adaptor.

Inflating Truck and RV Tires

Most tire inflators are designed for cars and motorcycles. Although they appear to deliver sufficient PSI, most don’t actually have the power to inflate truck and RV tires. For under 30 bucks you can add a heavy-duty model that will inflate any vehicle tires quickly and easily.

Tried and True Advice

Regular maintenance is key to air compressor performance, and even oil-free models need to have the tank drained regularly. It’s only a 5-minute job so don’t overlook it. Also, don’t be put off by size. Large air compressors are just as easy to operate as portable models, so consider your performance needs carefully before deciding on a compressor. — Bob Beacham

Air Compressor Maintenance Tips

There are a number of air compressor tips and tricks that can help you get the most out of your tool, but none is more important than knowing how to look after it properly. The good news is that not any of these tasks are difficult or take very long.

- It bears repeating: Read the manual. Nobody knows better how to look after your air compressor than the people who made it.

- Drain the tank after each use. Moisture left inside can cause rust. The air compressor should be turned off before draining.

- Check the oil level and change it regularly (does not apply to ‘oil-free’ models). The air filter will also need to be cleaned or replaced.

- Check the pressure release valve/switch to make sure it is operating correctly. This prevents over-pressurization.

- Hoses and fittings can wear eventually so check for air leaks. These can reduce tool performance, and leaks can make the motor work harder than necessary to maintain pressure. Change if necessary.

- Air compressors vibrate so check occasionally for loose nuts, bolts, and screws. Plus, always check it whenever you notice a change in the sound it makes.

Final Thoughts

If you only need to staple or nail a few times, there’s little point investing in an air compressor. On the other hand if you’re getting serious about home auto repair, woodworking, home remodeling, or crafts and hobbies, they are well worth considering. These are remarkably versatile tools and, as this how to use an air compressor guide has shown, they are surprisingly easy to operate. Many corded or cordless tools can also be bought as a pneumatic (air-driven) version. Air tools are often cheaper than their cordless counterparts, offsetting the initial cost of the compressor. They also have fewer moving parts so they are usually more durable.

There are numerous benefits to owning these tools, which is why they are found in so many pro workshops. Now that you know how easy it is to use an air compressor, it might be time to add one of the best home air compressors to your home toolkit.

4 Types of Air Compressors to Know

Technically speaking, air compressors can be described as reciprocating, axial, screw, vane, centrifugal, or scroll. However, most of these apply to large commercial or industrial models, and are not relevant in this air compressor for beginners article. The ones we are detailing are reciprocating, which means they use one or more pistons.

However, there are different types of reciprocating compressors that are popular in homes and workshops. These types show the potential air compressor uses around the house.

1. Tire Inflators

Some people argue that tire inflators are not true compressors because they don’t store air in a tank. Nevertheless, they do compress air to inflate vehicle or bicycle tires, plastic pools, balls, kayaks, and paddle boards. They usually run off a 12V DC outlet (cigarette lighter) making them very convenient for leisure trips. They are compact and lightweight enough to stow in the trunk.

Our Recommendation: EPAuto 12V DC Digital Tire Inflator at Amazon for $29.97

This model was tested and earned a spot among our picks for the best portable air compressors. It has a display that not only gives clear readings but can be used to set an auto shut-off when the correct pressure is reached.

2. Portable

Portable (or compact) air compressors are the most popular choice for tasks around the house and yard. They can be powerful enough to drive tools like sanders and nailers, yet are light enough to carry easily from one place to another. There are a variety of different designs (pancake and hotdog for example) and performance options. An increasing number of cordless models are becoming available providing the ultimate in freedom of movement.

Our Recommendation: Makita MAC2400 Portable Air Compressor at The Home Depot for $389

We were impressed with Makita’s powerful and reliable compressor with two ports during our in-depth test and review. It’s tough to beat for a wide range of DIY and home workshop tasks.

3. Horizontal

Although there are exceptions, horizontal air compressors are usually more powerful than portable models. They have larger tanks that can deliver more consistent pressure, and the lower demands on the motor makes them more durable. There are single- and two-stage models, the latter effectively compressing the air twice for higher performance. They do tend to be larger, of course, so space may be an issue. It’s important to check dimensions before buying. Increased weight also reduces portability, so many have wheels.

Our Recommendation: California Air Tools 8010 Air Compressor at Amazon for $201.62

This took the top spot in our best quiet air compressor review. It provides competitive performance for DIYers and amateur auto enthusiasts, and it is terrific value for money.

4. Vertical (or Upright)

Vertical air compressors are very much like horizontal models, but they have a much smaller footprint. It’s often easier to find space in a garage or workshop for one of these devices. Controls, connectors, and gauges are near the top of the machine which many find convenient as it reduces the need to bend over. Vertical air compressors tend to be powerful, high capacity tools that can be noisy, so it’s a good idea to check the decibel rating.

Our Recommendation: Stealth 20-Gallon Ultra Quiet Air Compressor at The Home Depot for $369

This is a high-performance model that was best in class when we looked at air compressors for home garages. It would also make a great choice for keen home woodworkers or those taking on a substantial remodeling challenge.