We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Sandpaper on a tools and materials list may seem like an easy enough item to check off. That is, until you hit the hardware store and face stacks of sandpaper sheets and booklets, each distinctly identified with different numbers that indicate sandpaper grits.

Each sandpaper grit performs a different job. Generally, the lower the grit number, the more coarse the grit. Therefore, a sheet of 220-grit sandpaper is more coarse than a sheet of 400-grit sandpaper. Coarser grits are used for heavy sanding on rough and uneven surfaces, while fine- grit sandpaper is used to polish and finish the surface of materials. Usually more than one type—and often three types—is needed for most projects.

It’s helpful to learn about different sandpaper grits so you can find the right sandpaper for your next project.

What do sandpaper grit numbers mean?

Sandpaper consists of fine particles from either natural or synthetic sources. The particles (also known as grains or grit) are sifted through screens and sorted by size before being bonded with adhesive to a paper, sponge, or cloth-type backing to create an abrasive material.

In the United States, grit is determined based on a gradation scale established by the Coated Abrasive Manufacturers Institute (CAMI). The higher the number, the finer the sandpaper grit. Most sandpaper follows the CAMI scale, but if you order sandpaper online, you may run across sandpaper grit sized by the Federation of European Producers of Abrasives (FEPA).

Grit sized with the FEPA scale is indicated by the letter “P” preceding the grit number. FEPA sizes are not identical to CAMI sizes, but you can find a very similar option by selecting one of the two closest FEPA numbers.

Sandpaper Grit Chart

Here’s a quick reference that will help you find the right sandpaper grit for the job at hand. Make sure to check out the “common uses” column if you are unsure of which grit to use on the project, and always test on an inconspicuous spot or scrap material when using new sandpaper.

| Grade | CAMI | FEPA | Description | Common Uses |

|---|---|---|---|---|

| Extra coarse | 24, 30, 36 | P12, P16, P30, P36 | 530 to 1,815 micrometers |

|

| Coarse | 40, 50 | P40, P50 | 336 to 425 micrometers |

|

Medium | 60, 80 | P60, P80 | 190 to 265 micrometers |

|

| Fine | 100, 120 | P100, P120 | 115 to 162 micrometers |

|

| Very fine | 150, 180, 220 | P150, P180, P220 | 190 to 265 micrometers |

|

How to Choose the Right Sandpaper Grit

Manufacturers may indicate sandpaper grit by the number or by describing it, so it’s helpful to know what each description means.

- Extra-coarse sandpaper (24 to 36 grit): Used for removing paint and varnish; sanding old floors might also require extra-coarse sandpaper.

- Coarse sandpaper (40 to 50 grit): Used to roughly shape wood and remove previous finishes, such as light coats of polyurethane.

- Medium sandpaper (60 to 80 grit): Primarily used to sand rough wood and remove scratches and planning marks.

- Fine sandpaper (100 to 120 grit): For most DIY projects, this sandpaper will suffice for final smoothing before the work is finished.

- Very fine sandpaper (150 grit or higher): Often used between coats of paint or varnish as well as for finishing.

On many projects, you’ll start with a coarse sandpaper grit, then gradually switch to finer grits to obtain a smooth finish.

Types of Sandpaper Grit Material

Most sandpaper manufacturers list on their product labels the type of material best suited for sanding. However, it’s smart to know what type of grit material to look for before you shop. The following are the most common types of sandpaper materials that DIYers may encounter.

1. Flint

Flint sandpaper’s surface has pulverized flint (or quartz) that creates its textured surface. It’s the oldest type of sanding paper and known for being inexpensive. A natural grain, flint is not durable and is traditionally used for light sanding and polishing. It can be rinsed after sanding jobs for repeated use.

Best For: Light sanding, removing varnish and paint

Our Recommendation: 3M Scotch-Brite Flint Super Fine Sanding Sheet at All Industrial Tool Supply for $0.16 per sheet.

Flint is a natural material that works well on tough sanding products.

2. Emery

Emery sandpaper features a natural grain that’s most often used for removing corrosion and/or polishing steel and other metals. The edges of its particles can be too sharp for sanding wood, and it’s best for deburring, paint removal, or mechanically finishing a surface.

Often referred to as emery cloth, the abrasive is actually glued to a cloth rather than a paper so it is actually a little more durable than sandpaper.

Best For: Removing corrosion, polishing steel, deburring, paint removal

Our Recommendation: LYFJXX Emery Cloth Roll at Amazon for $13.98.

Emery cloth is a durable sanding material that’s used for tough sanding jobs, such as deburring or paint removal.

3. Garnet

Another natural grain, garnet is slightly softer than flint and emery. Used for polishing and fine sanding of wood, leather, and plastic, it tends to dull relatively quickly when used to sand metal. While it will wear quickly while it’s being used, the rapid wear helps to create a finer finish on the surface it’s sanding. Some use it for power sanding, but it’s also used as a hand sander.

Best For: Polishing and fine sanding of wood, leather, and plastic

Our Recommendation: 3M Garnet Sandpaper at Amazon for $3.69.

Garnet sandpaper is used for polishing and fine sanding of multiple materials and wears quickly.

4. Zirconia Alumina

Until ceramic was used, zirconia alumina was the most abrasive grain available for sanding projects. A synthetic product, this grit is long lasting and ideal for grinding away burrs on metal and for an initial sanding of rough wood. When it’s used for sanding metal, the grit particles can actually become sharper, so you won’t have to change sandpaper frequently.

Best For: Grinding away metal burrs and sanding rough wood

Our Recommendation: ABN Zirconia Alumina Sandpaper Disc Set at Amazon for $13.99.

One of the most abrasive types of sanding materials, zirconia alumina is often sold as belts and discs for tough projects.

5. Aluminum Oxide

Another very durable synthetic grit, aluminum oxide is well suited for sanding and polishing various types of metal, including bronze and alloy steel. It’s known for being long lasting and can be found in a variety of grits from fine to coarse. Aluminum oxide is also a good choice for sanding all types of hardwoods.

Best For: Sanding hardwood and various types of metal

Our Recommendation: 3M Aluminum Oxide Sandpaper 6-pack at Ace Hardware for $4.59.

A general-purpose sandpaper that’s available in a variety of grits, aluminum oxide is durable and long lasting.

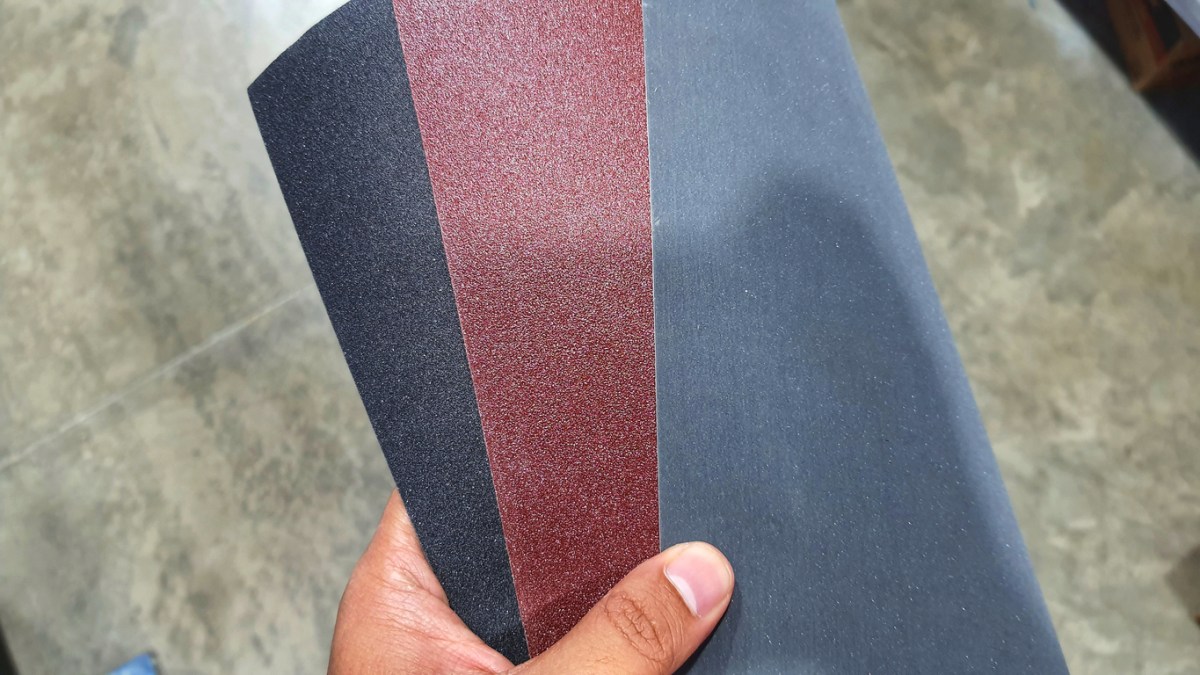

6. Silicon Carbide

Often used for automotive projects or wet sanding projects like polishing marble or stone, silicon carbide is made in coarse grits that can remove rust and in less-coarse grits for polishing. The most durable of all synthetic abrasives, silicon carbide is good for sanding a wide range of materials, including plastic, metal, hardwoods, and softwoods.

Best For: Sanding plastic, metal, hardwoods, and softwoods

Our Recommendation: LotFancy Silicon Carbide Dry Wet Sanding Sheet at Amazon for $8.99.

Silicon carbide sandpaper is often offered in a range of 80 to 3,000 grit, making it a versatile type of sandpaper for many different kinds of projects.

Looking for the best type of sanders for your sanding project? See our guides to the best random orbital sanders, the best palm sanders, and the best detail sanders.