We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Must-Have Tools to Simplify DIY

Whether you’re a rookie handyman or a seasoned do-it-yourselfer, everyone needs some basic gear to complete basic around-the-house tasks. If you haven’t had to repair holes in drywall, assemble furniture, or sand your deck yet, don’t worry, your day will soon come. Here are the tools that will help you cut, connect, repair, and measure the things that need to be done around the house.

Combination Square

The combination square is adjustable, consisting of a rigid steel rule, typically 12 inches long, with a headpiece that slides along its length. The headpiece has both a 90-degree edge and one that forms a 45-degree angle with respect to the rule. It’s ideal for marking (and checking) both 90-degree crosscuts and miter cuts. A bubble level in its handle makes the combination square useful for leveling as well. (Available at Amazon.)

Torpedo Level

The torpedo level’s sealed vials contain water, alcohol, or another clear liquid and an all-important air bubble. Each tube or vial is slightly curved and has two parallel lines drawn at its center. When the bubble is aligned between the hairlines, it indicates that the object being trued is perfectly vertical or horizontal, depending on the orientation of the vials and how the level has been placed on the object. It’s great for use in tight spaces, and is small enough to be carried in a pocket or tool belt. (Available at Amazon.)

Handsaw

A basic handsaw has a blade roughly 2 feet long that tapers from the heel (at the handle) to its toe. It’s most commonly used for simple cutoff work, when it’s quicker to grab a handsaw than a power saw. The teeth may be designed for cutting across the grain (crosscut saws) or for cutting with it (ripsaws). A 10- or 12-tooth crosscut saw is a good, basic model that can also rip a board if necessary. This 16-inch saw from WilFiks, which has a nonslip handle and a high carbon steel blade, is one to consider. (Available at Amazon.)

Electric Drill

A basic electric drill consists of a motor built into a pistol-shaped body. Instead of a gun barrel, though, there’s a gripping device called a chuck into which one of a wide variety of drill bits are inserted. Older models lock the bits in place using a key that tightens the chuck, but most new drills use a keyless chuck that requires only the grip of your hand to tighten it. Use electric drills, like this one from Black+Decker, to make holes, drive screws, stir paint, grind metal and more. (Available on Amazon.)

C-Clamps and Bar Clamps

When working with wood in particular, clamps are essential for pulling together pieces that need to be glued and for holding them tight and flush until the glue sets. For most around-the-house jobs, C-clamps or bar clamps will do the trick. C-clamps have jaws in the shape of the letter C. Bar clamps are usually larger, with a fixed jaw at one end and another on a tail slide that moves up and down the bar’s length. These bar clamps from IRWIN have pads that prevent them from scuffing your workpieces. (Available on Amazon.)

Related: 7 Tools That Contractors Swear By

Random Orbital Sander

A convenient, one-handed tool, the random orbital sander is driven by an electric motor. The motor spins a shaft on which a counterweight is mounted, causing the sander to spin and wiggle, never the same way twice. The tool does a neat job, producing little or no scratching across the grain. Using prefabricated sandpaper disks, which are available in coarse and fine grits, an orbital sander—like this one from Black & Decker—can remove lots of material quickly or produce a fine finish. (Available on Amazon.)

Staple Gun

A staple gun can be used to fasten all kinds of materials in home construction and maintenance work. Roofing contractors, insulation installers, and carpenters as well as homeowners and hobbyists find a multitude of uses for staplers every day. Staple guns, like the Arrow model pictured here, come in hand-powered and electric models, although the most common variety is powered by a spring. (Available on Amazon.)

Locking Pliers

Adjustable pliers are useful as a hand-held vice or clamp. They lock firmly onto a workpiece, usually one of metal. They are also known as plier wrenches, lever-wrench pliers, and by the proprietary name Vise-Grips. Locking pliers are sold in several designs (with long-nose, flat, and even C-clamp jaws), but the standard design has serrated, straight jaws. Irwin’s Vice-Grips are made of alloy steel and come with a built-in wire cutter. (Available on Amazon.)

T-Bevel

Though the bevel gauge, or T-bevel, is a near relation of the square, its purpose is to help fabricate pieces that are not square. (It’s especially helpful when working on old homes, where walls and floors may not be at standard angles.) The tool consists of a handle (or stock) with a blade that’s attached with a wingnut. The blade fits into a groove cut into the head of the stock, and when the nut is loosened the blade can rotate 360 degrees and fabricate any angle in relation to the handle. (Available on Amazon.)

Carpenter's Square

The carpenter’s square is actually an L-shaped tool, usually with a 2-inch-wide, 24-inch-long leg perpendicular to a 1-1/2-inch-wide, 16-inch-long tongue. The most common use is for framing, laying out and marking patterns for framing, roofing, and stairway work. It’s also useful as a straightedge for determining the flatness of a surface, and for marking cutoff work on wide stock. (Available on Amazon.)

Related: 7 Tools with Hidden Talents

Plumb Bob

You don’t need a graduate degree in physics to understand that a string suspended with a weight at the bottom will be both precisely vertical, or “plumb,” and perpendicular to any level plane through which it passes. The plumb bob, obviously, is the companion tool to the level. Well-machined and well-balanced bobs, like this one from General Tools, have pointed tips that make them more precise to use. (Available on Amazon.)

Handheld Circular Saw

The Skilsaw, or circular handsaw, is the one of the power tools most often found in the average homeowner’s tool chest. It’s easy to use, affordable, and astonishingly flexible and practical. It’s designed to cut boards to size, typically using a 7 ¼-inch-diameter blade, but can also cut through metal, plastic, and concrete. The circular saw is a powerful and efficient tool, but one that can cause grave injury—be sure to follow safety precautions when using it. (Available on Amazon.)

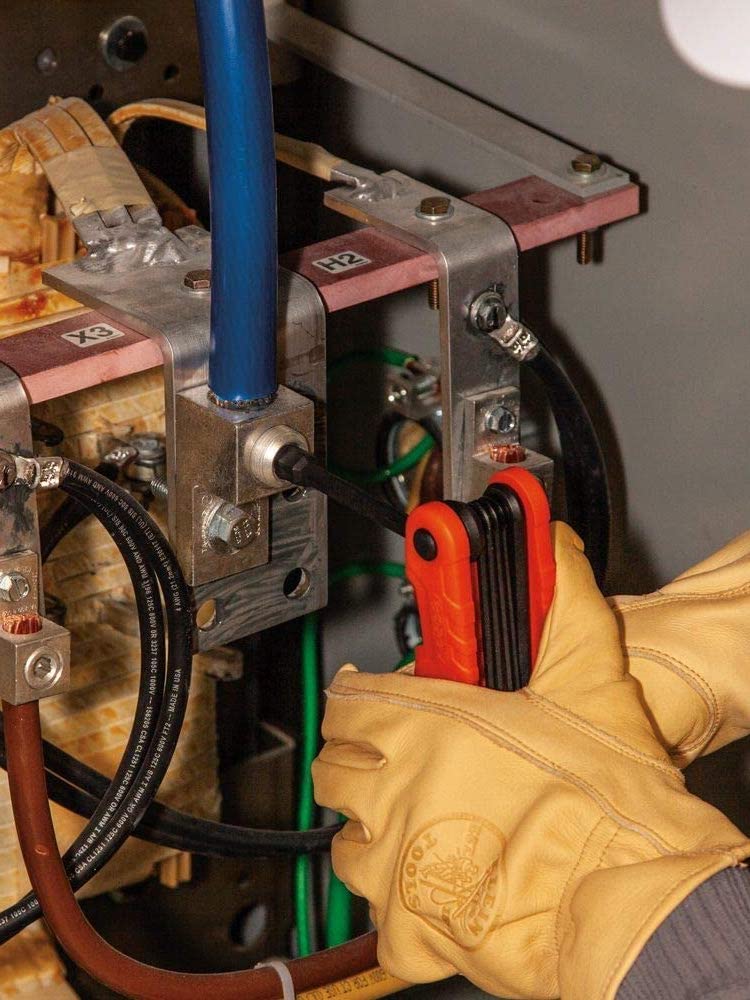

Hex Keys

Also known as Allen wrenches, hex keys are familiar tools to anyone who has bought furniture from IKEA. Though you might have a few throwaway hex keys with which you’ve assembled flat-packed furniture, it’s a good idea to have a quality set in your toolbox. These keys are useful for mounting towel bars and other bathroom accessories, repairing bicycles, and for other projects in which hexagonal bolts or recessed-head screws need to be adjusted. This folding hex key set from Klein Tools has a comfortable grip and keeps hex keys in 11 sizes corralled, rather than lost in your junk drawer. (Available on Amazon.)

Putty Knife

Putty knives are the tools of choice for simple drywall repairs: Simply scoop some joint compound with a putty knife, apply it to the damaged area, and smooth the compound with the knife’s edge. This simple tool is also used to apply thinset when making minor tile repairs, spackle nail holes, or scrape old wallpaper out of tight spaces. If you’ve painted a window shut, running the putty knife’s blade between the window frame and its sash should loosen the dried paint. Putty knives are available in a variety of sizes, but we find the 2- and 3-inch models, like this 3-inch model from Warner, most versatile. (Available on Amazon.)

Stud Finder

Stud finders help DIYers locate 2×4 wall studs behind drywall so that they can anchor heavy items like mirrors, bathroom towel bars, TVs, and shelving securely. Drywall alone will crumble under heavy weights, and without anchoring them into wood studs your TVs and treasures will tumble to the ground. Some stud finders, like this one from VIVREAL, can also detect metal pipes, joists, rebar, and live AC wires. (Available at Amazon.)

Utility Knife

Utility knives are good for far more than opening cardboard boxes—they can slice through rope, drywall, plastic, roofing shingles, rubber, linoleum, wallpaper and other materials. These knives’ sharp blades can even score soft metals. Though they are an essential, versatile tool for every household, utility knives must be handled with care: Protect the blade when the knife is not in use, store refill utility blades in a secure place, and keep the knife and blades out of the reach of children. Though many utility knives have retractable blades, we also like Workpro’s folding version, which has an anti-slip ABS grip and comes with five replacement blades. (Available on Amazon.)

Tape Measure

A quality tape measure is an indispensable device for completing DIY tasks and general around-the-house upkeep: Will that new fridge fit between your kitchen cabinets? How many square feet of wood flooring do you need for the living room? You won’t get far without a retractable tape measure, like this 25-foot model from Komelon. (Available at Amazon.)

Safety Glasses

Though they can’t locate, measure, cut, or grip, safety glasses protect your most precious tools: your eyes. Wear these glasses to protect your peepers so that flying debris—such as glass, metal particles, and sawdust—does not injure your eyes as you work. If your project involves wielding a blow torch or using pesticides or other chemicals, again, eye protection is essential. Look for safety glasses that are approved by the American National Standards Institute (ANSI), like these from Dewalt. (Available on Amazon.)

Flashlight or Headlamp

A good flashlight or headlamp is crucial when you’re executing a tricky task, even more so if that task is in the basement, under a sink, or behind an appliance. Look for an LED light that allows you to adjust the light’s brightness, and the breadth of the beam. We are partial to headlamps so you still have two free hands to work. This headlamp from Fenix has a built-in micro-USB charging port, and can be detached and used as a mini-flashlight. (Available at Amazon.)

Crescent Wrench

Great for gripping, turning, and tightening, a quality wrench is a key component to every toolbox. A crescent wrench has one adjustable jaw and one fixed jaw, which allows you to use it on nuts and bolts in a variety of sizes. (Turn the screw at the bottom of the wrench’s head to adjust the jaws.) This tool is useful for plumbing and auto repair, or for other instances in which you have to adjust fasteners in close quarters. To keep your hand from slipping while using a crescent wrench, make sure that the wrench’s jaws have a close grip on the fastener before turning it. (Available on Amazon.)