We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

One of the biggest innovations in the housing market has been the introduction of 3D-printed homes, which builders can create faster and more affordably than those made with standard construction practices. Thus far, 3D-printed homes have primarily been made from concrete, but a company called Azure is set to change the game by offering a more eco-friendly option.

According to the Environmental Protection Agency, the construction and demolition industry sends more than 145 million tons of waste to landfills every year. Concrete makes up 85 percent of that waste.

Rather than using concrete, Azure uses recycled plastic to craft its structures. In fact, more than 60 percent of the materials that make up Azure homes come from recycled plastic that is used in water bottles and food packaging. Until now, Azure has only created small backyard structures, but the company’s next move is to offer full-sized homes from this eco-friendly process.

RELATED: See Inside Habitat for Humanity’s First 3D-Printed Home—and the Future of Construction

How are these structures made?

Azure launched in 2019 because co-founders Ross Maguire and Gene Eidelman had a vision of creating homes more quickly, affordably, and sustainably. They recognized that the construction industry was notorious for going over budget and not staying on schedule, and dreamed of offering an alternative. Not to mention, the construction sector is the “largest global consumer of raw materials globally” and is “responsible for approximately 20 percent of the world’s total carbon emissions,” according to the brand.

Azure recently opened a 15,000-square foot factory in California to house its custom-made 3D printer, which will eventually produce homes that the company can ship across the country. Clients will work with Azure to customize the design of their structures, and select the materials, colors, and other details they want.

Once the design is complete, printing will take only 24 hours. Because the process is so quick, Azure aims to deliver end products much more quickly than those made using traditional construction practices. Azure estimates that its 3D-printed homes are 20 to 30 percent cheaper than homes made from standard building materials and can be completed 70 percent faster.

RELATED: 30 Kit Homes You Can Buy and Build Yourself

How much do the 3D-printed structures cost?

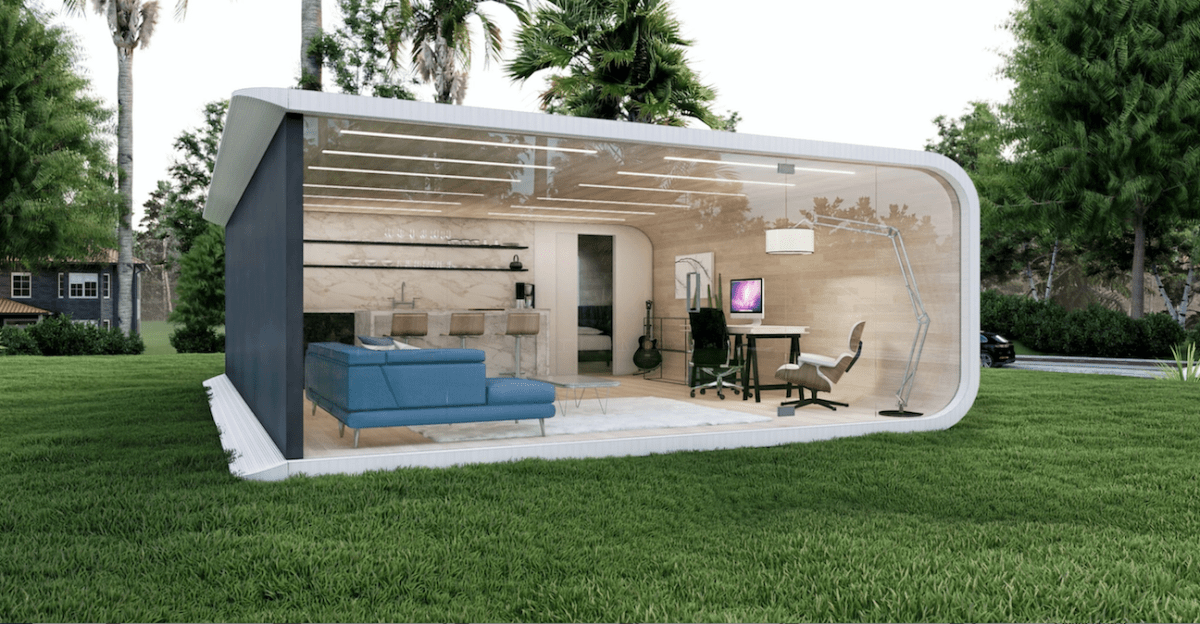

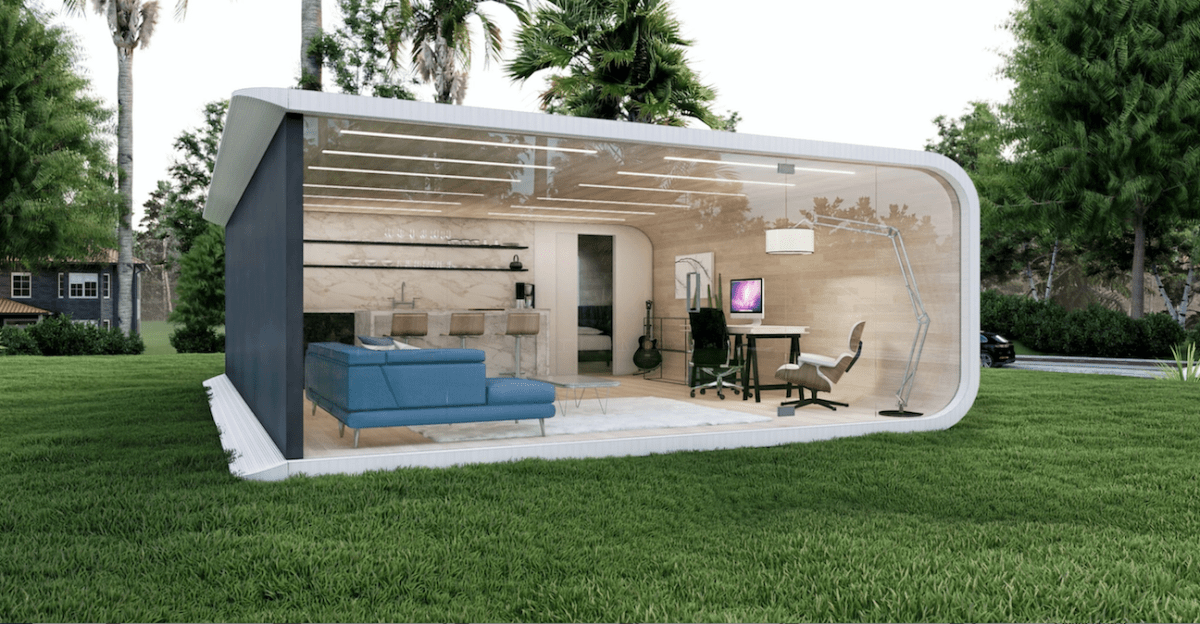

Azure is currently offering pre-orders for two kinds of structures: backyard studios and accessory dwelling units, or ADUs. The backyard studios measure 120 square feet and therefore don’t require building permits in most municipalities across the U.S. Prices start at $23,900 and vary depending on buyers’ design specifications. These small spaces can be used as home offices, gyms, game rooms, artist studios, and more.

The ADUs are larger, measuring 450 square feet or more. Prices start at $99,900 for these more spacious structures, which can be used as guest houses or income units.

Each structure is preassembled in Azure’s California factory and installed by Azure’s team upon delivery. It takes approximately three days to connect the structures to local utilities like water and electricity, meaning these 3D-printed units can be up and running in little time.

If you’re considering purchasing a 3D-printed structure from Azure, they are currently available to pre-order for delivery on or after July 1, 2022.