We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Oscillating tools are the multi-tool of saws, capable of performing diverse tasks ranging from cutting and grinding to scraping and sanding. But an oscillating tool will only perform these functions well when fitted with the proper blade. Oscillating tool blades come in various shapes and sizes, from fine-tooth straight models that make precision plunge cuts to large circular blades for long straight cuts. More specific types include blades with carbide teeth that can cut through hard metal, Japanese blades for executing smooth cuts through wood, and even diamond-coated blades for grinding through tile grout.

With so many options on the market, it can be challenging to determine the most suitable saw blade for the job. This guide will plunge deep into the crucial features to consider when shopping for the best oscillating tool blades and highlight some of our top favorites.

- BEST OVERALL: Vtopmart Oscillating Tool Blades Kit

- BEST BANG FOR THE BUCK: Leiluo Oscillating Multi-Tool Blade Kit

- BEST FOR CUTTING: Pecham Universal Oscillating Quick Release Saw Blades

- BEST FOR GROUT REMOVAL: DeWalt Oscillating Carbide Grout Removal Blade

- BEST QUICK-RELEASE: Herkka 23-Piece Oscillating Multi-Tool Saw Blade Kit

- BEST FOR SCRAPING: Dremel Universal Quick Fit Flexible Scraper Blade

- BEST BLADE KIT: Gulrear 60-Piece Oscillating Multi-Tool Blade Kit

How We Chose the Best Oscillating Tool Blades

In building our list of oscillating tool blades, we made sure to focus our research on a broad range of options that suit most of the well-known brands, such as DeWalt, Bosch, and Dremel. The majority of our top recommendations are suitable for any tool brand, so they’re flexible enough for most shoppers to consider.

We also made sure to offer a selection of the two popular blade types, each providing specific benefits depending on the project at hand. Plunge-cut blades are great at precision cuts with handy measurements on the side, while segment saws excel at cutting holes in the middle of drywall, for example.

Regarding material, we focused on quality blades made from carbide, which is durable and suitable for frequent heavy-duty work, and high-carbon steel, which is a bit more affordable and great for odd jobs.

Our Top Picks

The oscillating blades below take into account our considerations outlined later provide shoppers with options across a range of categories.

Best Overall

Vtopmart Oscillating Tool Blades Kit

Oscillating blade tools face harsher conditions than most manual saws. This is largely due to the amount of friction the oscillating motion of the power tool creates, which can quickly wear down lesser blades. These blades are thicker than most oscillating saw blades and consist of high-carbon steel, making them harder. This translates into blades that will hold their edge longer than typical oscillating saw blades.

This 20-piece kit is also versatile, with six different kinds of saw blades for cutting wood, metal, and plastic. Long, wavy teeth on each blade allow them to cut faster and smoother. Each blade has inch measurements on one side and centimeter measurements on the other, allowing for precision cuts. These blades are also compatible with most brands of oscillating tools, including Ryobi, Fein MultiMaster, Milwaukee, Hitachi, Craftsman, and Black+Decker.

Products Specs

- Number of pieces: 20

- Compatible material: Wood, plastic, and metal

- Blade type: Plunge cut

Pros

- Thicker and more durable than similar options on the market; will wear down more slowly

- These blades can fit the majority of oscillating tool brands

- Achieves faster and smoother cuts with long, wavy blade teeth

Cons

- Blades can start to dull quickly when used on harder materials

Get the Vtopmart oscillating tool blades at Amazon or Vtopmart.

Best Bang for the Buck

Leiluo Oscillating Multi-Tool Blade Kit

Those who use oscillating tools on a regular basis can go through a lot of blades. This kit, which is available in a 50- or 100-blade set, keeps the cost of new blades down with its bargain per-piece price. This set includes a variety of blades for cutting a range of different materials, including PVC, laminate, soft wood, plastic, gypsum board, and melamine. Each blade has metric measurements on one side and imperial measurements on the other, allowing for precision cuts.

Its universal mounting design fits most oscillating tools, including DeWalt, Milwaukee, Ryobi, Kitachi, and Craftsman. Keep in mind, however, that these blades won’t work with Bosch, Makita, Dremel models, and certain Fein models, which will require a separate adapter purchase.

Products Specs

- Number of pieces: 50 or 100

- Compatible material: PVC, laminate, soft wood, plastic, gypsum board, and melamine

- Blade type: Plunge cut

Pros

- Includes a large number of multi-tool blades; great for frequent users of this type of tool

- Has both metric and imperial measurements on either side for maximum precision

- For a 50-pack set of blades, the price point is competitive compared to similar options

Cons

- Will not fit on certain Bosch, Makita, or Fein power tool models

- Also requires an adapter to fit some Dremel models (sold separately)

Get the Leiluo oscillating tool blades at Amazon.

Best for Cutting

Pecham Universal Oscillating Quick Release Saw Blades

With its variety of blade types and a design that makes each of these able to cut through wood or metal, this 24-piece set from Pecham will cover most cutting tasks performed with an oscillating tool. This set comes with an impressive variety of blade types, including standard-tooth, Japanese-tooth, and precision-tooth saw blades, each of which is designed specifically for cutting wood, plastics, or metal. Each blade is made of high-carbon and stainless steel, ensuring they’ll hold their edge longer than other blades. They also feature an electrophoretic black finish, which gives them an extra layer of defense against corrosion.

Built-in measurement markers on each side of the blade for inches and centimeters speed up the cutting process by eliminating the need to take measurements with another tool. This set is compatible with most oscillating tool brands.

Products Specs

- Number of pieces: 24

- Compatible material: Wood, plastic, and metal

- Blade type: Plunge cut and segment saw

Pros

- Wide selection of blade types to choose from; great for a variety of uses

- Built to fit a wide range of manufacturer tools; suitable for most popular brands

- Comes with C-clip adapters that fit to additional brands, which some blades do not include

Cons

- Blades may bend if put under too much pressure; not ideal for heavy-duty projects

Get the Pecham oscillating tool blades at Amazon.

Best for Grout Removal

DeWalt Oscillating Carbide Grout Removal Blade

Removing grout is a laborious process that can quickly wear out some of the best grinding blades. With its carbide construction, this blade is significantly harder than other steel alloy blades that can burn up more quickly. This allows it to cut more easily through grout. Although this blade is significantly more expensive than other oscillating tool blades, it will hold its edge longer, eliminating the need to repeatedly change out worn blades.

This model features an innovative wave shape that chews through grit up to twice as fast as other blades while also creating wider cuts, eliminating the need to make multiple passes with the blade. And, even though this is a DeWalt blade, it’s compatible with most major brands of oscillating tools.

Products Specs

- Number of pieces: 1

- Compatible material: Grout

- Blade type: Segment saw

Pros

- Manufactured by a well-established and reputable tool brand; high quality

- Fits a range of popular oscillating tool brands, not just DeWalt

- Innovative wave shape helps cut through grout much faster than standard blades

Cons

- While this high-quality blade is directly from a popular tool brand, single blade is expensive

Get the DeWalt oscillating tool blades at Amazon,Lowe’s, The Home Depot, Walmart, or Acme Tools.

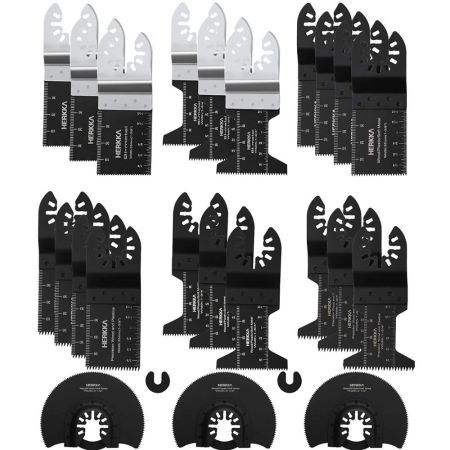

Best Quick-Release

Herkka 23-Piece Oscillating Multi-Tool Saw Blade Kit

Even the best oscillating saw blades will burn out fairly quickly, especially when doing a large job like grinding out all the grout in a bathroom or cutting through metal pipe. With that in mind, being able to quickly swap out blades is crucial to keeping the job moving forward. These blades from Herkka pop quickly out of an oscillating tool, making changing blades on the fly easy.

They’re also compatible with a wide range of popular brands, including Ryobi, Milwaukee, Chicago, and Hitachi. This set includes seven different types of saw blades, including three circular blades for cutting through plastic, metal, and wood. The blades’ purpose is clearly labeled on the side, eliminating confusion. Each blade has metric and imperial measurements for quick reference.

Products Specs

- Number of pieces: 23

- Compatible material: Wood, plastic, and metal

- Blade type: Plunge cut and segment saw

Pros

- Quick-release design helps users change out blades quickly and easily

- Surprisingly good-quality material that can last for several uses before getting dull

- Can easily stand up to more expensive rivals in terms of longevity; great affordability

- Comes with a handy storage box to help keep the blades protected from moisture

Cons

- Could do with including a few more O-rings to help attach to certain tool brands

Get the Herkka oscillating tool blades at Amazon or Kmart.

Best for Scraping

Dremel Universal Quick Fit Flexible Scraper Blade

Those who need their oscillating blade for a variety of DIY projects will want to consider adding this option from Dremel to their collection. This 2-inch blade is suitable for removing grout and caulk as well as scraping, sanding, and grinding. For convenience, the universal Quick Fit scraping blade can be used with Dremel, Bosch, Milwaukee, Rockwell, and Makita oscillating tools.

The oscillating blade is a flexible scraper that works in hard-to-reach areas and should be used at a 30- to 45-degree pitch for best results.

Product Specs

- Number of pieces: 1

- Compatible material: Removing caulk, coats of peeling paint, and other soft adhesives

- Blade type: Scraper blade

Pros

- Highly versatile tool; ideal for scraping, sanding, and grinding

- Compatible with multiple brands of oscillating tools for convenience

- Flexible blade is ideal for preparing smooth surfaces for projects

Cons

- Flexible blade only used for softer scraping applications (doesn’t cut through things)

Get the Dremel oscillating tool blades at Amazon, Ace Hardware, Walmart, Grainger, or Menards.

Best Blade Kit

Gulrear 60-Piece Oscillating Multi-Tool Blade Kit

This large 60-piece kit of multi-tool blades is a great choice for shoppers who need enough blades to keep them going through larger, more demanding projects. These blades from Gulrear are made with high-speed and high-carbon steel, with an additional electrophoretic finish on top to ensure long-lasting protection against corrosion.

Gulrear’s multi-tool blade kit is designed to fit most oscillating tools available on the market, notably Fein Multimaster, Ryobi, Milwaukee, Black+Decker, DeWalt, and Craftsman. These blades may not be suitable for certain Dremel models, though.

To keep such a large number of oscillating blades organized, this kit includes a plastic storage box that’s moisture- and dustproof. This protects the blades from rusting while sitting on the shelf.

Products Specs

- Number of pieces: 60

- Compatible material: Wood and plastic

- Blade type: Plunge cut

Pros

- These blades have an added electrophoresis layer that helps prevent rust

- Kit includes a large plastic storage container that helps protect blades from dust and moisture

- Can fit the majority of tool brands, some requiring a small adapter to fit

Cons

- Struggles with cutting any sort of hard metal; blades can dull quite quickly

Get the Gulrear oscillating tool blades at Amazon.

Jump to Our Top Picks

What to Consider When Choosing Oscillating Tool Blades

Understanding an oscillating tool blade’s shape and consistency is crucial to getting the most out of it. Here’s a closer look at the characteristics of oscillating tool blades.

Purpose

Their small size makes oscillating tool blades ideal for cutting in places where circular saws, jigsaws, and other conventional saws are too big to do the job.

Oscillating blades can cut many different materials, including metal, plastic, wood, masonry, and drywall. Universal blades can cut plastic, wood, or soft metals. Blades designed specifically for metal are capable of cutting through harder metals, while Japanese-style saw blades are adept at making smooth cuts through wood.

Some blades feature scraper edges ideal for removing caulk or for pulling up old wallpaper or linoleum. Special diamond-coated blades are suitable for grinding through mortar and cement.

To avoid confusion, most manufacturers print what materials the blade can cut through on the sides of the blade.

Because of their ability to cut through various materials—and their ability to make plunge cuts—oscillating tool blades are often ideal for small jobs, such as cutting openings out of drywall, trimming baseboards, cutting pipes, grinding out old grout, and lopping off nail heads.

Material

Oscillating saw blades are made from a variety of metal types.

High-carbon steel has a higher carbon content, which makes the steel harder and stronger. A high-carbon blade is sharper and will hold its edge longer.

Carbide is a steel alloy that includes tungsten, which makes it much harder than other steel alloys, giving it a longer life and faster cutting speed.

Bi-metal blades consist of two different types of steel: conventional steel, which comprises the body of the saw blade, and high-speed steel, which is used for the teeth and holds its hardness even at high temperatures.

As with carbide blades, a bi-metal blade cuts more quickly and is more durable than other steel alloys. Keep in mind that bi-metal blades and carbide steel blades typically cost more.

Blades designed for wood have a Japanese saw-blade style, which features blade teeth that cut in both directions. Speciality blades with diamond coatings are suitable for grinding through brick, cement, and even glass.

Some blades feature a black electrophoretic finish, which improves the blade’s wear while protecting it from corrosion.

Blade Types

Cutting blades come in three different types: plunge-cut blades, segment saw blades, and scraper blades.

- Plunge-cut blades have a square shape with a flat edge and come in various lengths. The two flat sides typically have measuring strips, which serve as handy guides for determining the depth of the cut. These measuring strips, coupled with the blade’s shape, allow for the blade to make more precise plunge cuts.

- Segment saw blades are circular. This circular profile is handy when making cuts in the middle of a material, such as when cutting a rectangle out of a piece of drywall.

- Scraper blades simulate the look of a manual scraper with a broad, smooth edge that can slide under or behind materials like sheet flooring or bathroom caulk.

Features

Some tools have added features designed to improve usability or extend the life of the blade. Most straight-edge blades feature metric and imperial measurements on the sides, making it easier to gauge the depth of a cut.

Since oscillating saw blades tend to wear out quickly, most blades have a quick-release system. This allows the operator to quickly change blades on the fly, which can be particularly useful for applications such as grinding out grout or cutting metal, which can wear an edge out in less than an hour.

Tool Compatibility

Oscillating blades attach to the oscillating tool via a C-shaped piece located on the inside of the blade. Grooves cut into the piece are designed to fit most oscillating tools, all of which have universal mounting bracket patterns.

That said, not all oscillating tools will work with all blades. Some brands use Starlock blades, which use a special star-shape to fit the blade to the tool. Starlock fittings create a tighter connection, allowing for better power transfer between the blade and the tool. The Starlock system also doesn’t require a hex key, making blade changes much faster. Only certain blades are compatible with Starlock oscillating tools.

FAQs

Here are some of the most frequently asked questions from shoppers wondering what oscillating tool blades can cut or how long they last.

Q. Are oscillating tool blades universal?

Most oscillating tool blades are universal, allowing them to fit most oscillating tool brands. Newer Starlock oscillating tools are the exception. Blades that fit this type of oscillating tool must be Starlock compatible.

Q. Can an oscillating tool cut nails?

Oscillating tools can easily cut through nails and screws when fitted with a metal cutting blade.

Q. How long can a typical oscillating blade last?

This can vary, depending on what the oscillating blade is cutting. Cutting through metal or drywall will wear out a blade much faster than cutting through wood. Running the oscillating tool at a higher speed will also heat the blade to a higher temperature and cause it to wear out more quickly. With that in mind, for lighter-duty use, a blade may last for an entire day. For heavy-duty applications, a blade may wear out in less than 1 hour.

Why Trust Bob Vila

Bob Vila has been America’s Handyman since 1979. As the host of beloved and groundbreaking TV series including “This Old House” and “Bob Vila’s Home Again,” he popularized and became synonymous with “do-it-yourself” home improvement.

Over the course of his decades-long career, Bob Vila has helped millions of people build, renovate, repair, and live better each day—a tradition that continues today with expert yet accessible home advice. The Bob Vila team distills need-to-know information into project tutorials, maintenance guides, tool 101s, and more. These home and garden experts then thoroughly research, vet, and recommend products that support homeowners, renters, DIYers, and professionals in their to-do lists.