The 5 Tools HGTV Star Keith Bynum Can’t DIY Without

Well-made, high-quality basic tools are the backbone of any tool collection.

Well-made, high-quality basic tools are the backbone of any tool collection.

Is the arching allure of a spider plant drawing you into its web? Learn spider plant care and propagation tips that will help your spider plant babies grow and thrive.

Switching up details such as the order in which you wash your dishes—and what you wash them in—can get them cleaner quicker. Try mixing up your routine today!

Here's how to score a Milwaukee 5.0Ah battery—a $169 value—for free.

Display the Stars and Stripes proudly, but make sure that you're flying Old Glory properly and respectfully.

Want to stash your stuff out of sight, out of mind? We have ideas.

The top early Prime Day EGO Power+ tool deals include blowers, mowers, trimmers, and more. Hurry, these prices won’t stick around.

Create the perfect atmosphere for your outdoor spaces with these cool and classy fans.

Make these easy changes to your garden and you’ll be hosting these stunning creatures all season long.

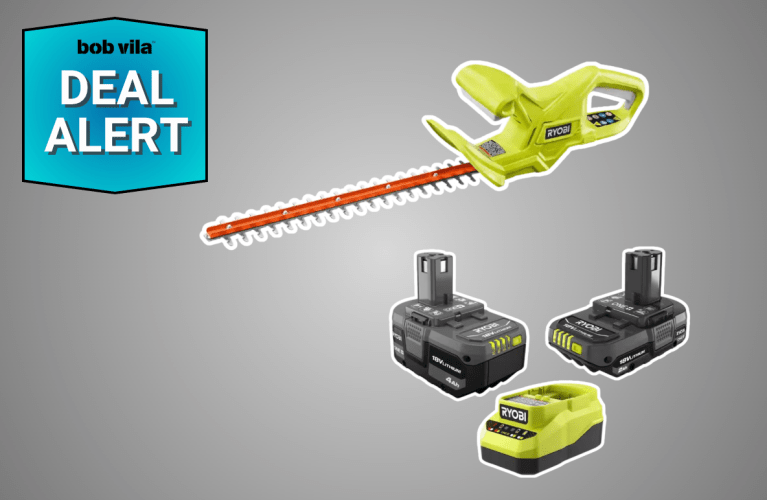

For a limited time, score a $79.95 Ryobi 18-inch hedge trimmer free when you pick up the $99 Ryobi One+ battery starter kit—an easy upgrade for anyone already eyeing summer yard work.

Use these crafty cord-management solutions to resolve your wire woes and stay plugged in.

The best moving container companies offer an easy and convenient compromise between an arduous DIY move and an expensive full-service moving company.

Tiny brown bugs can be a nuisance indoors, but identifying the culprit is the first step toward getting rid of them for good.

Keep your house cooler and save money on your electric bill by sealing these common air leaks.

Real estate agents know which plants appeal to homebuyers, so heed their advice when planting your yard for a quick, top-dollar sale.

Should you remove mushrooms in your yard or leave them be? Why do they grow there in the first place? Your questions, answered.

Amazon has already slashed prices on Makita blowers, chainsaws, and combo kits ahead of Prime Day 2025.

An excess of minerals in your water can leave soap scum in your sinks, clog your faucets, and even alter the taste of food. Here's how to know for sure if your home has hard water.

It doesn't take a major renovation to make a big impact on your home's exterior. See how big a difference a little imagination, paint, or some flowers can make.

From cooking to cocktails, borders to planters, fresh herbs add flavor to life, food, and gardening.